Multifunctional soil remediation equipment combining leaching remediation and thermal desorption remediation

A technology of soil remediation and thermal desorption, which is applied in the field of multifunctional soil remediation equipment, can solve the problems of energy waste and heat that cannot be recycled, and achieve the effects of saving energy, improving repair effects, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

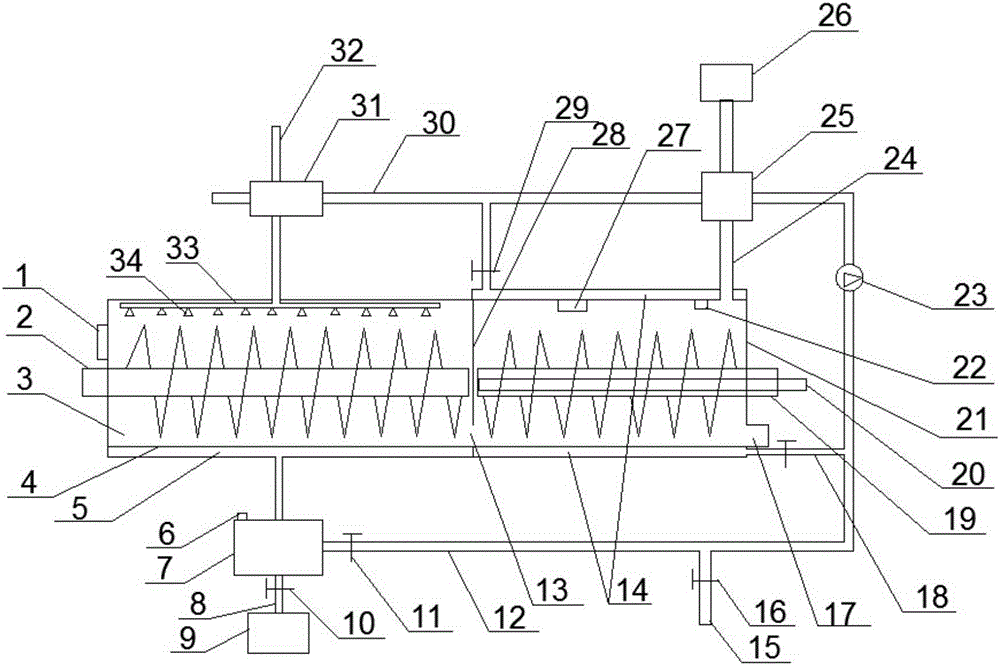

[0029]A kind of multifunctional soil remediation equipment combined with shower repair and thermal desorption repair, comprising a repair box, the repair box is provided with a partition 28, and the partition 28 divides the repair box into a spray repair chamber 3 and a thermal desorption chamber. Repairing room 21, the side wall of the repairing box located on the side of the spray repairing room 3 is provided with a feed inlet 1, and the side wall of the repairing box located on the side of the thermal desorption repairing room 21 is provided with a discharge port 17, the spraying A first screw conveyor 2 is horizontally arranged in the shower repair room 3, a second screw conveyor 19 is horizontally arranged in the thermal desorption repair room 21, and a through hole 13 is provided at the lower end of the partition 28; the spray repair room 3 is provided with a spray device, which communicates with the external rinse agent through the rinse agent inlet pipe 32, and the bott...

Embodiment 2

[0032] Based on Embodiment 1, the spraying device comprises a rinse agent spray pipe 33 and a shower head 34, and the rinse agent spray pipe 33 is horizontally arranged above the first screw conveyor 2, and the middle part of the rinse agent spray pipe 33 is connected to the spray nozzle. The agent inlet pipe 32 is connected, and the spray nozzles 34 are evenly distributed on the rinse agent spray pipe 33 and communicated with the rinse agent spray pipe 33 . The rinse agent spray pipe 33 arranged horizontally and the spray heads 34 evenly distributed on the rinse agent spray pipe 33 make the rinse agent spray evenly and improve the restoration effect.

Embodiment 3

[0034] Based on Embodiment 1, the soil heating device is a heating rod 20 , and the heating rod 20 is horizontally arranged in the rotating shaft of the second screw conveyor 19 . When the second screw conveyor 19 is working, the screw blades stir and transport the soil, and setting the heating rod 20 in the rotating shaft can make the soil evenly heated, and the soil is heated throughout the lateral movement process, which is conducive to the complete removal of organic pollution thing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com