Carbon fiber insulation hard felt and preparation method thereof

A technology of thermal insulation hard felt and carbon fiber, which is applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc. Easy to chalk and ageing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

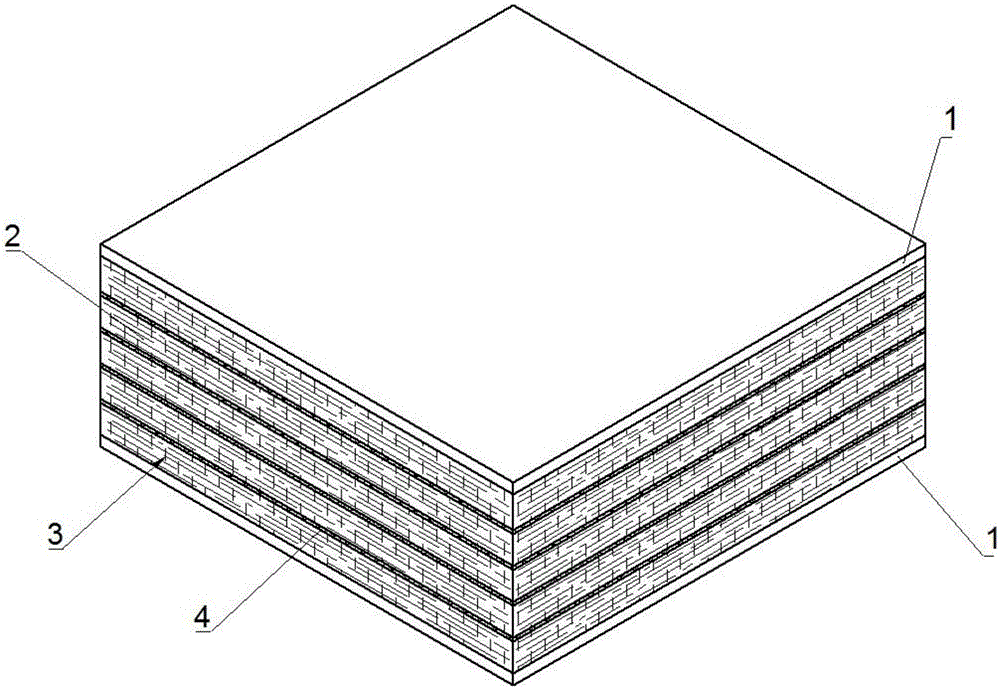

[0030] The invention provides a method for preparing a carbon fiber thermal insulation hard felt, comprising the following steps:

[0031] A) performing chopping, heating pretreatment, carding and opening, layer laying and acupuncture compounding of carbon fibers in sequence to obtain unit layers;

[0032] B) performing multiple times of sizing and drying the unit layer to obtain a treated unit layer;

[0033] C) superimposing and laying the multi-layer treated unit layers after sizing to obtain a composite unit layer;

[0034] After the uppermost layer and the lowermost layer of the composite unit layer are superimposed and laid with protective layers, hot pressing treatment and carbonization treatment are carried out to obtain carbon fiber thermal insulation hard felt; the heating procedure of the carbonization treatment is:

[0035] Raise the temperature to 1000°C at a heating rate of 20-50°C / h;

[0036] Then raise the temperature to above 1500°C at a heating rate of 30-7...

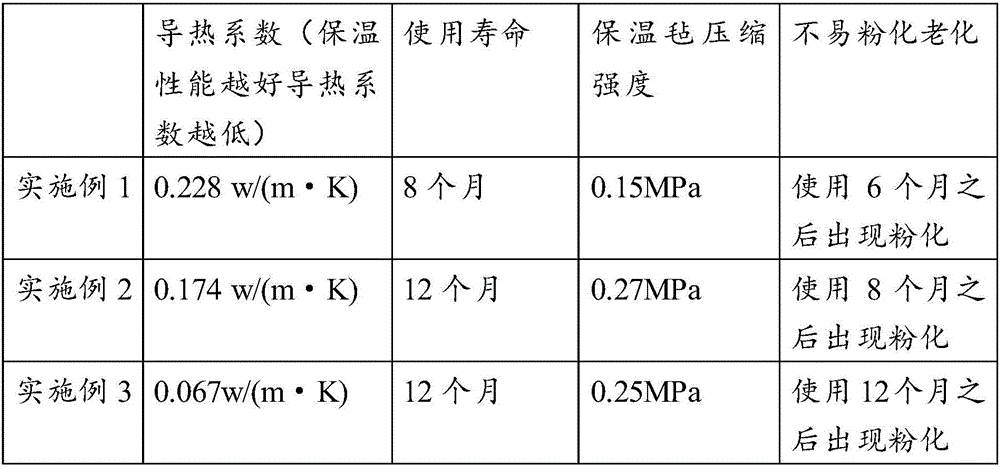

Embodiment 1

[0082] The PAN-based carbon fiber is chopped to 50mm, and heated at 50°C for 1 hour for pretreatment. Then, the raw material is fed from the feeding port of the carding machine, carded and opened by the carding machine, and then laminated.

[0083] Afterwards, the carbon fibers after laying are needle-punched, and the needle-punching is completed in a needle-punching machine. The fibers have a certain orientation, and more than 60% of the carbon fibers are in the same direction.

[0084] Glue was applied to the prepared unit layers by using a spraying device, and the amount of glue received by each unit layer was 22% (calculated by the weight increase percentage of the unit layer). Push the glue-sprayed unit layer into the drying room for drying at a temperature of 50°C for 0.5 hours. The glue used for sizing is a mixture of vinyl resin and water in a ratio of 1:7.

[0085] Use the spray device to spray glue on the upper and lower surfaces of the 10-layer treated unit layer....

Embodiment 2

[0092] The pitch-based carbon fiber is chopped to 90mm, heated at 120°C for 5 hours for pretreatment, and then the raw material is fed from the feeding port of the carding machine, carded and loosened by the carding machine, and then laminated .

[0093] Afterwards, the carbon fibers after laying are needle-punched, and the needle-punching is completed in a needle-punching machine. The fibers have a certain orientation, and more than 60% of the carbon fibers are in the same direction.

[0094] Put the unit layer into the inner cylinder of a horizontal centrifuge with a dipping tank, first add glue, and slowly rotate the inner cylinder while adding, so that the soft felt is completely soaked in glue, and the immersion time is 5 minutes; then drain the excess glue, and set The rotating speed of the centrifuge is: 1000 rpm; the time is: 2min, and the overall weight gain of the unit layer is controlled at 30%. The glue used for sizing is a mixture of epoxy resin and water in a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com