Non-woven fabric automatic packaging production line system and production process

A technology of automatic packaging and non-woven fabrics, applied in packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of not allowing the outer surface of non-woven fabrics to touch, high labor intensity, low packaging efficiency, etc., to prevent pollution Possibility, high equipment utilization, effect of reducing operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific implementation manners of the present invention will be further described below with reference to the accompanying drawings.

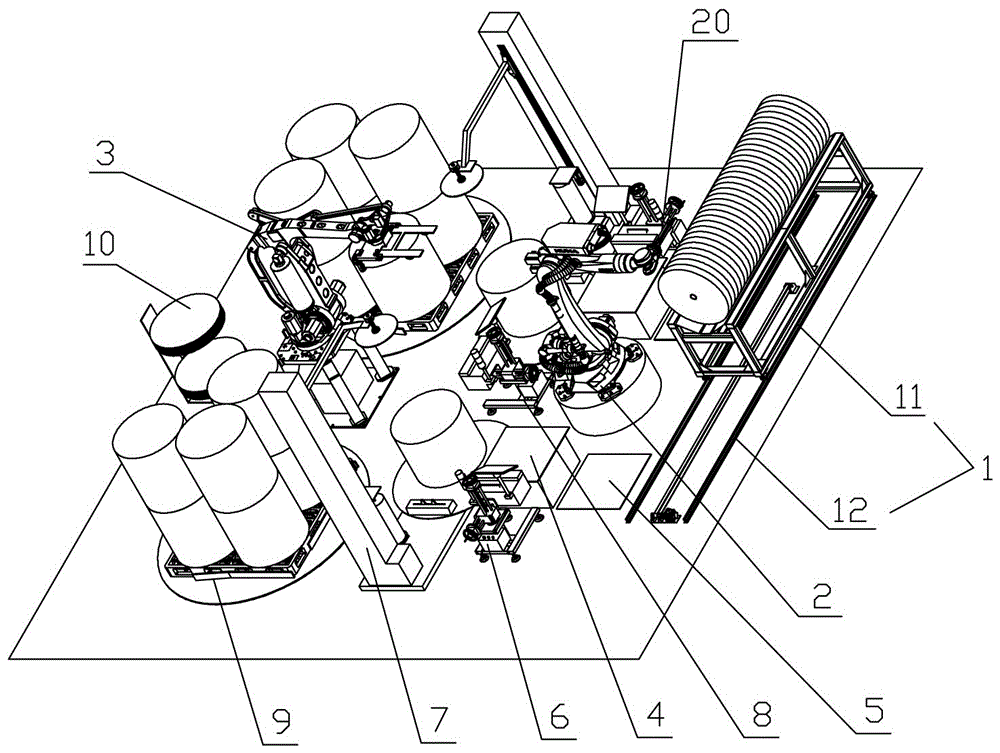

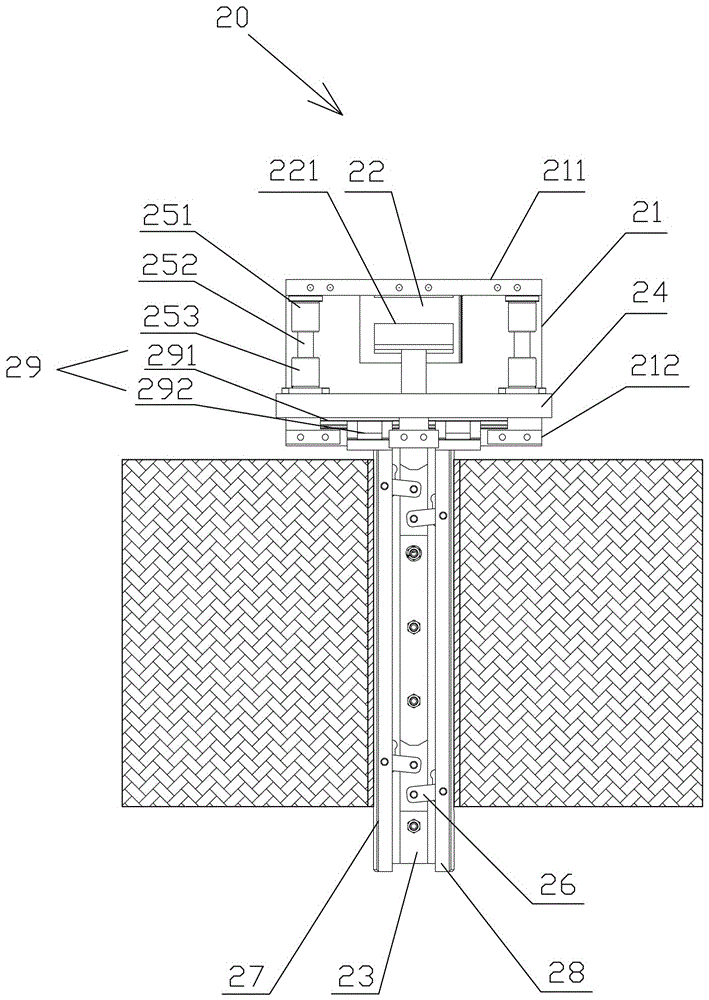

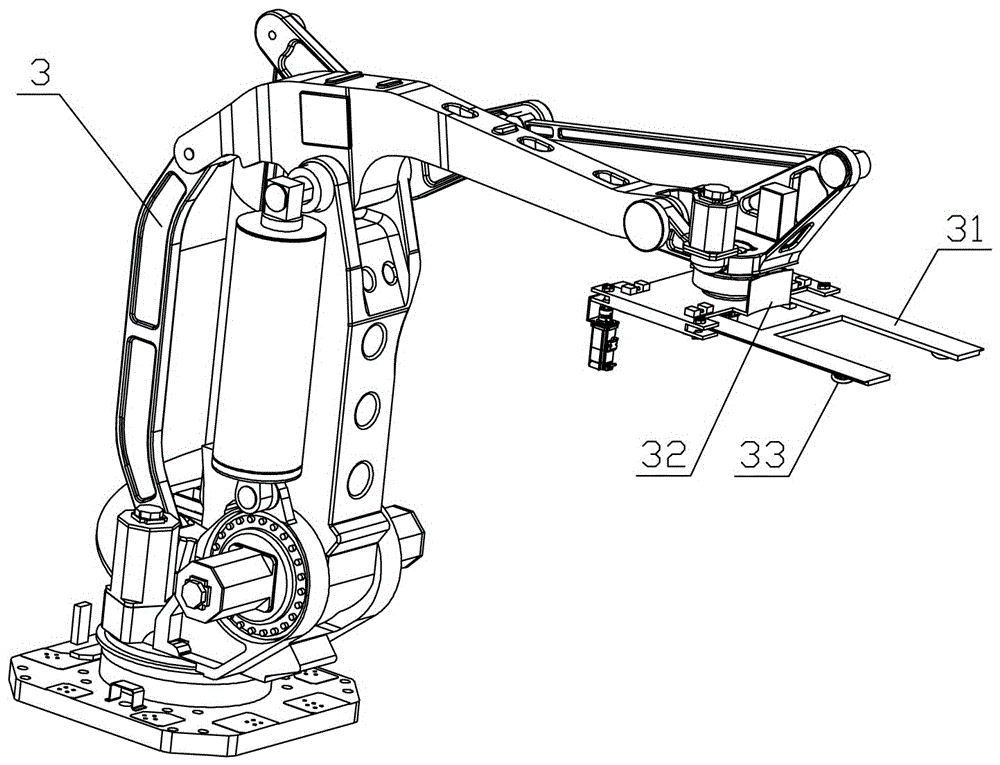

[0050] like figure 1 As shown, a non-woven automatic packaging production line system includes a self-propelled trolley 1 for transporting unpacked single rolls of non-woven fabrics, a six-axis articulated robot 2 for grabbing and delivering non-woven fabrics, and a robot for handling and A palletizing robot 3 for palletizing and packaging finished products, the palletizing robot 3 and the self-propelled trolley 1 are installed on the left and right sides of the six-axis articulated robot 2 respectively, and the self-propelled trolley includes a car Frame body 11, walking slide rail 12 and a photoelectric sensor (not shown in the figure due to viewing angle), the frame body 11 slides and runs on the walking slide rail 12, and the photoelectric sensor is used to control the vehicle At the sliding position of the frame body 11, a pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com