A polymer heavy metal flocculation device

A flocculation device, heavy metal technology, applied in flocculation/sedimentation water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of reduced treatment efficiency, long treatment time, poor adsorption effect, etc. , to achieve the effect of prolonging the service life, improving the adsorption effect and guaranteeing the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

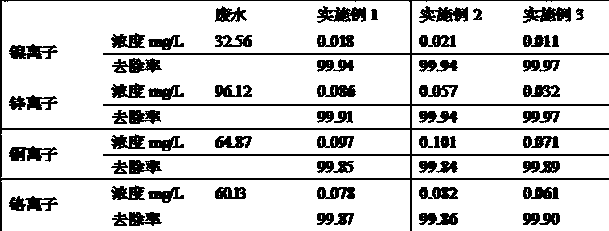

Embodiment 1

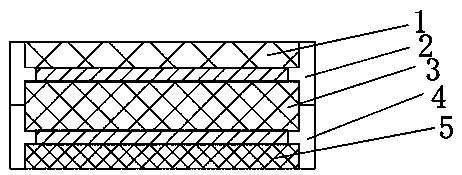

[0028] A polymer heavy metal flocculation device, comprising a filter plate 1, a first-level fixed aluminum plate 2, a first-level heavy metal flocculation plate 3, a second-level fixed aluminum plate 4, and a second-level heavy metal flocculation plate 5, the first-level fixed aluminum plate 2 and the second-level fixed The aluminum plate 4 is I-shaped, and is docked to form a cavity. A first-level heavy metal flocculation plate 3 is placed in the cavity. A filter plate 1 is arranged in the groove at the upper end of the first-level fixed aluminum plate 2. The second-level fixed aluminum plate 4. A secondary heavy metal flocculation plate 5 is arranged in the groove at the lower end, and the centers of the primary fixed aluminum plate 2 and the secondary fixed aluminum plate 4 are all provided with oblique grid hole plates, and the filter plate 1 is a stainless steel filter plate. The primary heavy metal flocculation plate 3 and the secondary heavy metal flocculation plate 5 a...

Embodiment 2

[0037] A polymer heavy metal flocculation device, comprising a filter plate 1, a first-level fixed aluminum plate 2, a first-level heavy metal flocculation plate 3, a second-level fixed aluminum plate 4, and a second-level heavy metal flocculation plate 5, the first-level fixed aluminum plate 2 and the second-level fixed The aluminum plate 4 is I-shaped, and is docked to form a cavity. A first-level heavy metal flocculation plate 3 is placed in the cavity. A filter plate 1 is arranged in the groove at the upper end of the first-level fixed aluminum plate 2. The second-level fixed aluminum plate 4. A secondary heavy metal flocculation plate 5 is arranged in the groove at the lower end, and the centers of the primary fixed aluminum plate 2 and the secondary fixed aluminum plate 4 are all provided with oblique grid hole plates, and the filter plate 1 is a stainless steel filter plate. The primary heavy metal flocculation plate 3 and the secondary heavy metal flocculation plate 5 a...

Embodiment 3

[0046] A polymer heavy metal flocculation device, comprising a filter plate 1, a first-level fixed aluminum plate 2, a first-level heavy metal flocculation plate 3, a second-level fixed aluminum plate 4, and a second-level heavy metal flocculation plate 5, the first-level fixed aluminum plate 2 and the second-level fixed The aluminum plate 4 is I-shaped, and is docked to form a cavity. A first-level heavy metal flocculation plate 3 is placed in the cavity. A filter plate 1 is arranged in the groove at the upper end of the first-level fixed aluminum plate 2. The second-level fixed aluminum plate 4. A secondary heavy metal flocculation plate 5 is arranged in the groove at the lower end, and the centers of the primary fixed aluminum plate 2 and the secondary fixed aluminum plate 4 are all provided with oblique grid hole plates, and the filter plate 1 is a stainless steel filter plate. The primary heavy metal flocculation plate 3 and the secondary heavy metal flocculation plate 5 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com