Self-repaired hydrogel and preparation method thereof

A hydrogel and self-healing technology, applied in the field of intelligent polymer materials, can solve the problems of high preparation cost, high price, and unproposed material repair ability, so as to reduce preparation cost, realize precise control and remote control, and realize remote The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

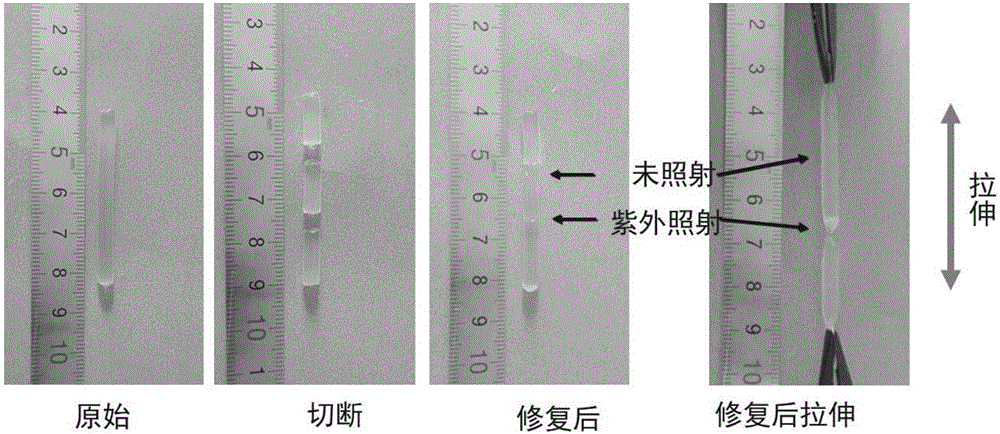

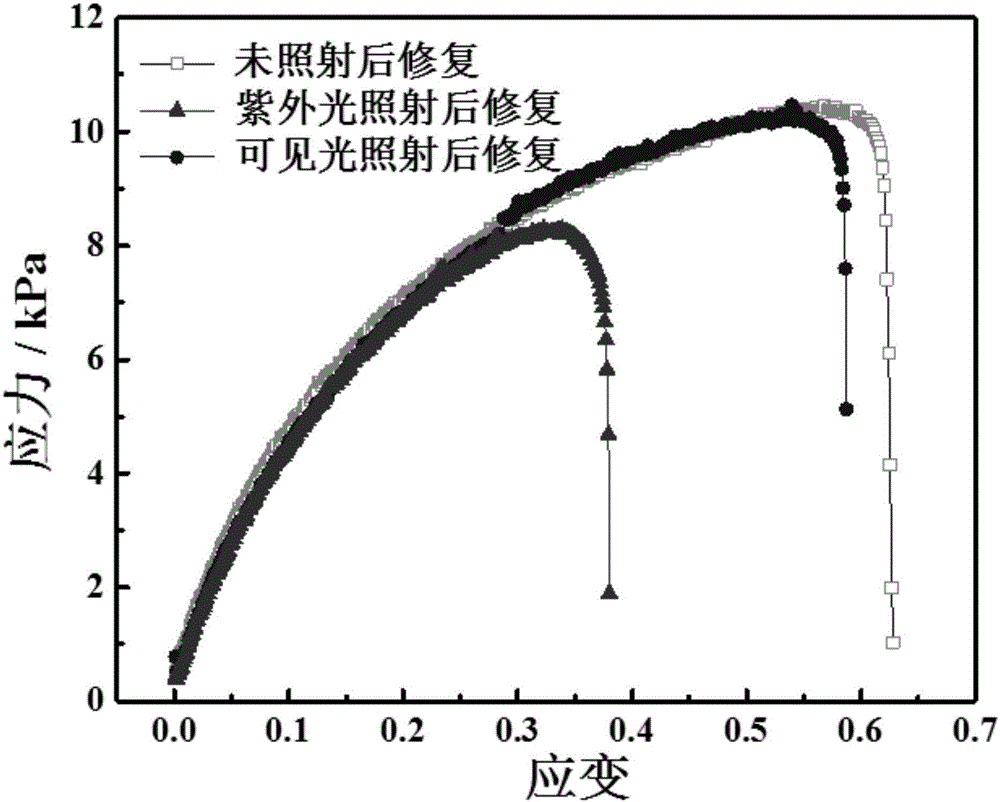

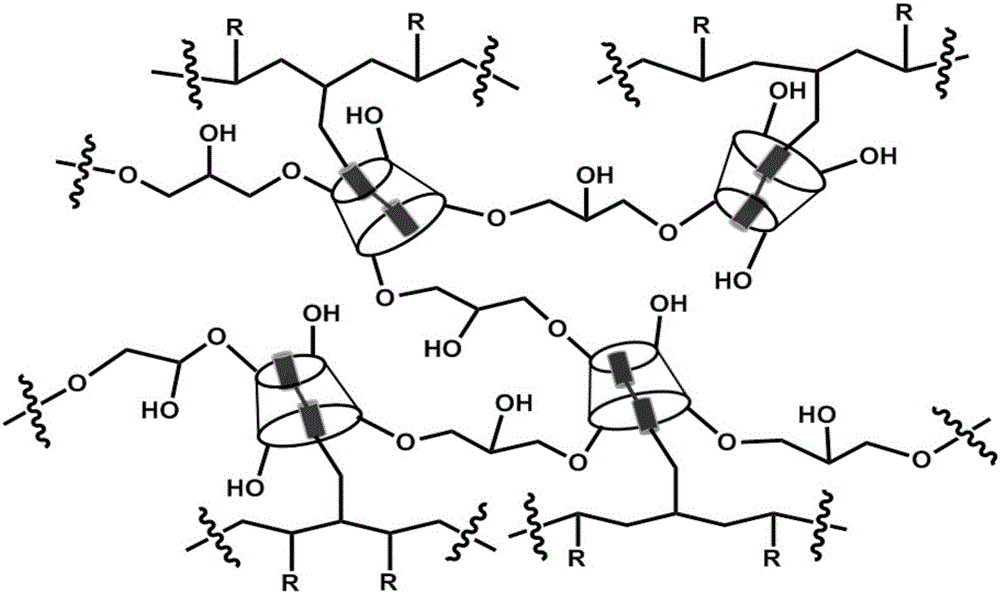

[0030]50 parts by mass of β-cyclodextrin and 30 parts by mass of NaOH were added to 100 parts by mass of water, and stirred at room temperature until a clear solution was obtained. The solution was heated and kept at 30° C., and then 30 parts by mass of epichlorohydrin was quickly added to react under constant temperature stirring. The reaction process was monitored, and when the solution became viscous after 4 hours of reaction, 50 parts by mass of acetone solution was added to terminate the reaction, and the acetone was removed with a rotary evaporator. Then use hydrochloric acid (6mol / ml) to adjust the pH of the solution to 10 and dialyze (dialysis bag molecular weight cut-off 3000), remove unreacted cyclodextrin, sodium hydroxide and epichlorohydrin, and dialyze for a week to obtain cyclodextrin- Epichlorohydrin copolymer solution, and then add 2 parts by mass of azobenzeneacrylamide to the cyclodextrin-epichlorohydrin copolymer solution, and stir and react at 20°C for 5h ...

Embodiment 2

[0034] Add 60 parts by mass of β-cyclodextrin and 40 parts by mass of NaOH to 100 parts by mass of water, stir at room temperature until it becomes a clear solution, heat the solution at a constant temperature of 30°C, and then quickly add 40 parts by mass of epoxy Chloropropane reacted under stirring at constant temperature. Monitor the reaction process, add 100 mL of acetone solution when the solution becomes thick after 2 hours of reaction, and stir for 3 minutes to terminate the reaction, and remove the acetone with a rotary evaporator. Then use hydrochloric acid (6mol / ml) to adjust the pH of the solution to 10 and dialyze (dialysis bag molecular weight cut-off 3000), remove unreacted cyclodextrin, sodium hydroxide and epichlorohydrin, and dialyze for a week to obtain cyclodextrin- Epichlorohydrin copolymer solution, and then add 4 parts by mass of azophenylacrylamide to the cyclodextrin-epichlorohydrin copolymer solution, and stir and react at 25°C for 24h until the solut...

Embodiment 3

[0038] Add 80 parts by mass of β-cyclodextrin and 60 parts by mass of NaOH to 100 parts by mass of water, stir at room temperature until it becomes a clear solution, heat the solution at a constant temperature of 20°C, and then quickly add 60 parts by mass of epoxy chlorine Propane reacted under constant temperature stirring. Monitor the reaction process, add 150 parts by mass of acetone solution when the solution becomes viscous after 0.5 hours of reaction, and stir for 5 minutes to terminate the reaction, and remove the acetone with a rotary evaporator. Then use hydrochloric acid (6mol / ml) to adjust the pH of the solution to 10 and dialyze (dialysis bag molecular weight cut-off 3000), remove unreacted cyclodextrin, sodium hydroxide and epichlorohydrin, and dialyze for a week to obtain cyclodextrin- Epichlorohydrin copolymer solution, and then add 6 parts by mass of azobenzeneacrylamide to the cyclodextrin-epichlorohydrin copolymer solution, and stir and react at 50° C. for 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com