Solar photovoltaic flame-retardant type white EVA packaging glue film and flame-retardant type double-glass photovoltaic component

A solar photovoltaic and packaging film technology, applied in photovoltaic power generation, adhesives, electrical components, etc., can solve problems such as trouble, increase installation cost, and difficulty in customer promotion, achieve strong weather resistance, reduce trouble, and laminate curing speed. Satisfying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

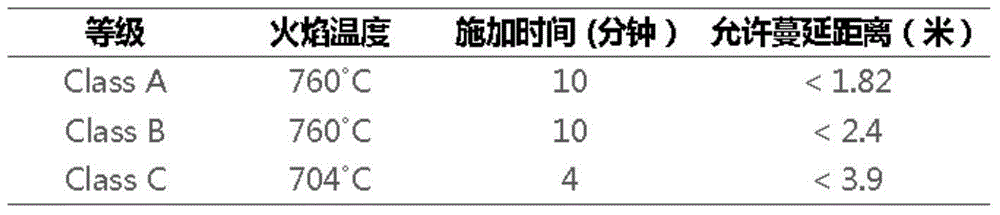

[0052] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0053] In order to verify the various performances of the flame-retardant white EVA packaging film of the present invention, 4 groups of flame-retardant white EVA packaging films obtained by using four sets of data from the 1st to 4th were tested respectively, each group of EVA packaging film The specific components and proportions of the film are listed in the following table, where the content of each component is expressed as: per 100 parts by mass of EVA, the mass parts added by other components:

[0054]

[0055]

[0056] According to the relevant data of the above 10 groups of flame-retardant white EVA packaging films, the following parameters of the 4 groups of flame-retardant white EVA packaging films were obtained through experiments:

[0057]

[0058] 1-10 groups of EVA encapsulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com