Water-based adhesive, and preparation method and application thereof

A water-based adhesive, water-based technology, applied in the directions of adhesives, bonding methods, carboxyl rubber adhesives, etc., can solve the problems of high price, low solid content and slow drying speed of water-based polyurethane adhesives, and achieve a simple and fast application method. , The effect of high adhesive strength and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

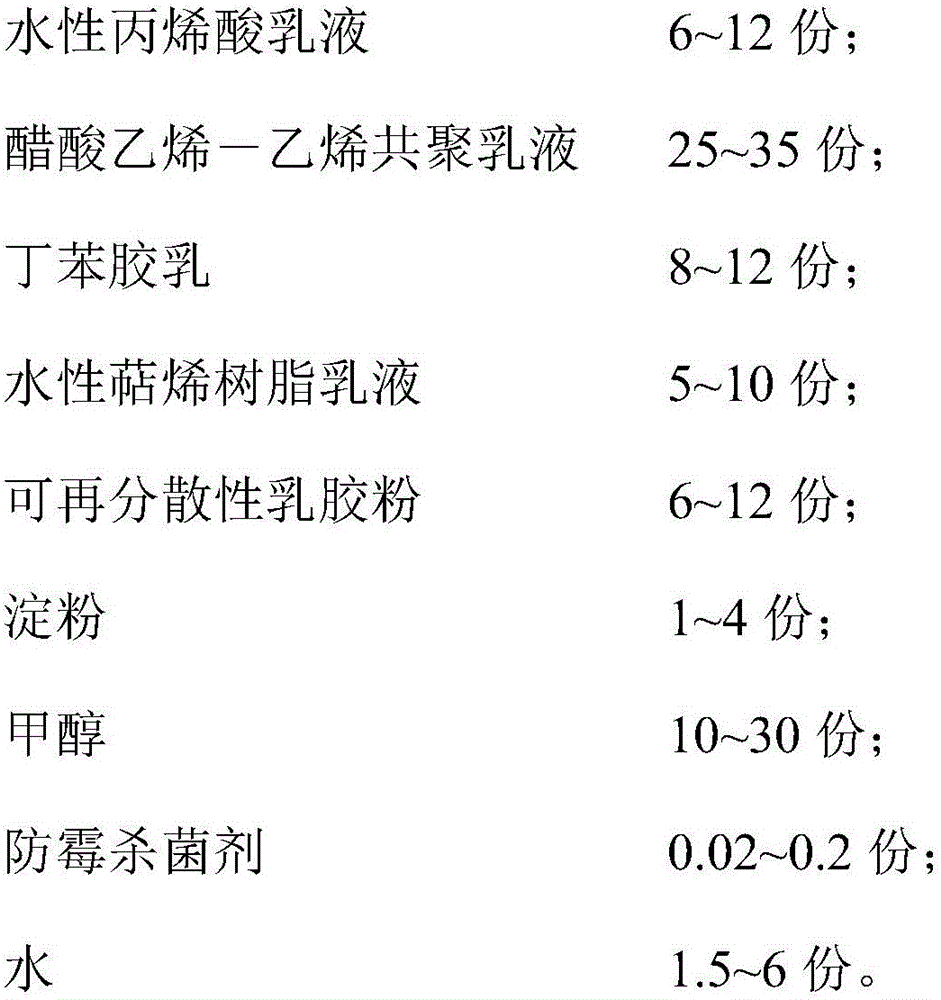

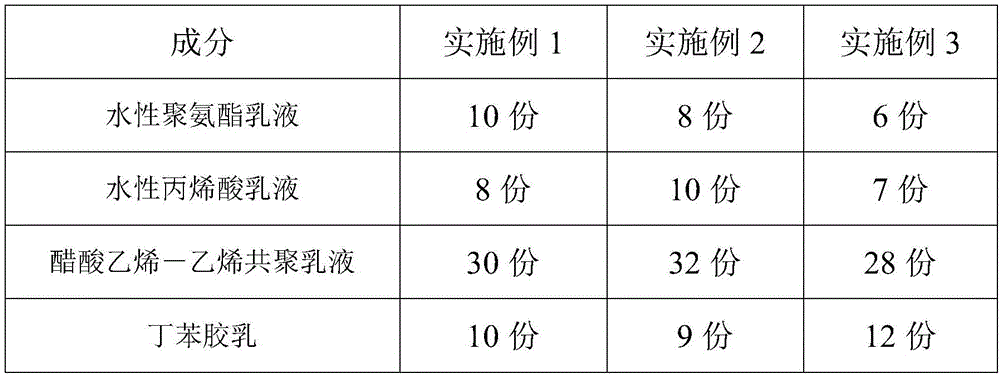

[0030] Embodiments 1 to 3 disclose a water-based adhesive, the components and parts by weight of which are shown in Table 1:

[0031] The composition and parts by weight of Table 1 Embodiment 1~3

[0032]

[0033]

[0034] The solid content in the composition is as shown in Table 2,

[0035] The solid content of table 2 embodiment 1~3 component

[0036]

[0037] Among them, the water-based polyurethane emulsion is purchased from Hefei Ketian Chemical Co., Ltd., and the model is KTA-715 water-based polyurethane dispersion adhesive.

[0038] The water-based acrylic emulsion is a water-based acrylic pressure-sensitive adhesive emulsion purchased from Wenzhou Runhong Adhesive Products Co., Ltd., model number ST-100.

[0039] The vinyl acetate-ethylene copolymer emulsion was a vinyl acetate-ethylene copolymer emulsion purchased from Sinopec Sichuan Vinylon Plant, model number CW40-716.

[0040] The styrene-butadiene latex was purchased from Foshan Junneng Chemical Co., ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com