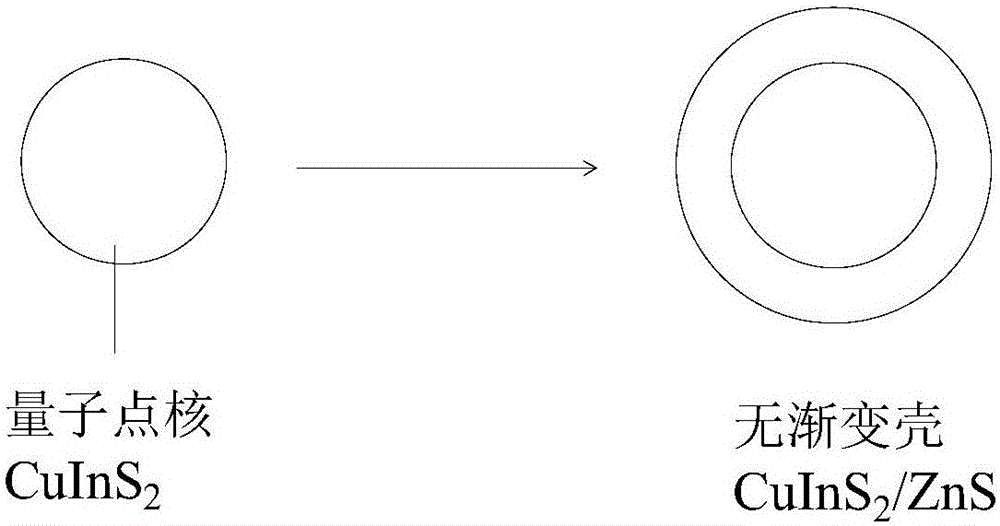

Cadmium-free core-shell quantum dot and preparation method thereof

A core-shell quantum dot and a technology for quantum dots, which are applied to the field of cadmium-free core-shell quantum dots and their preparation, can solve the problems of inability to effectively reduce the half-peak width, large lattice mismatch, limited improvement in fluorescence efficiency, etc., and achieve easy control. , Simple operation, realize the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

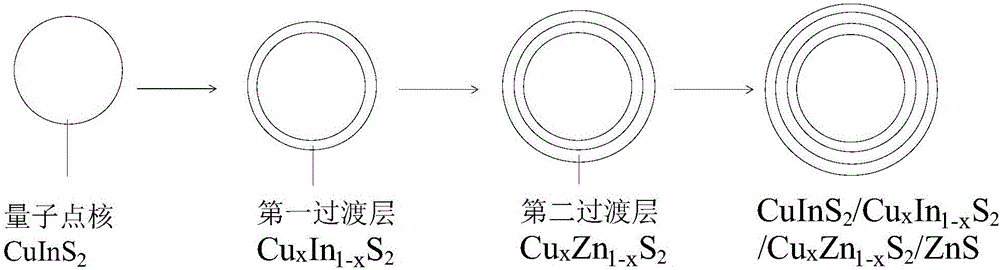

[0032] Correspondingly, the embodiment of the present invention also provides a method for preparing cadmium-free core-shell quantum dots, comprising the following steps:

[0033] S01. Preparation of quantum dot cores: providing nuclear cation precursors and nuclear anion precursors to prepare quantum dot cores;

[0034] S02. Prepare a gradient transition layer: add the quantum dot core, ligand reagent and solvent into the reaction vessel, and heat up to 120-300° C. after exhaust treatment;

[0035] Add nuclear cation precursors and nuclear anion precursors into the reaction vessel for the first reaction; follow this method for the second reaction in sequence... Nth 1 reaction, with the increase of the number of reactions, the molar amount of the nuclear cation precursor and / or the nuclear anion precursor gradually decreases, and the molar ratio of the nuclear cation precursor and the nuclear anion precursor is less than the specified The molar ratio of corresponding elements...

Embodiment 1

[0054] a CuInS 2 / Cu x In 1-x S 2 / Cu x Zn 1-x S 2 The preparation method of / ZnS cadmium-free core-shell quantum dot comprises the following steps:

[0055] S11. Extract 4ml of copper oleate containing indium oleate and 2ml and inject it into another three-necked flask and heat it to 180°C, then extract 0.2mmol of octamercaptan (OT) and inject it rapidly into the flask containing indium oleate and oil In the flask of acid-copper mixed solution, react for 3 minutes, and when the color of the mixed solution changes from green to blue and finally to yellow, extract 0.6 mmol of S-ODE solution and inject it into the mixed solution for 10 minutes, then react Stop heating the mixture until the temperature of the mixture drops to 100°C and maintain this temperature, extract 1ml of trioctylphosphine (TOP) and add dropwise at a rate of 1ml / h for 1h, after the addition, lower the temperature of the reaction mixture to room temperature. Finally, a precipitant was added to the mixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com