Shaft furnace process for producing iron coke

A technology for iron coke and shaft furnace, which is applied in the field of shaft furnace technology for producing iron coke, can solve the problems of poor thermal performance, difficult to achieve production effect, low iron ore ratio, etc., so as to reduce production cost, reduce temperature, reduce The effect of coke consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

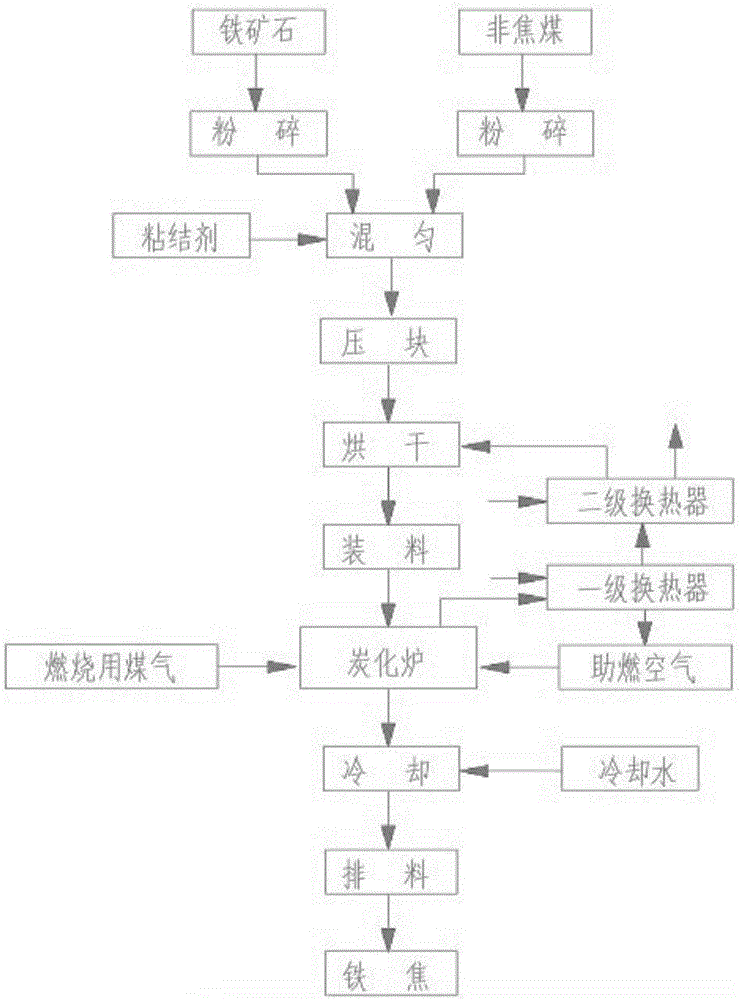

[0039] like figure 1 As shown, the present invention provides a shaft furnace process for producing iron coke, which is used to produce iron coke that replaces part of the blast furnace coke, and its main production steps include:

[0040] 1) Mix the iron ore powder (0.3mm) and coal powder with a qualified particle size after pulverization, and then briquette after mixing. The particle size of the briquette is 20-50mm, and then dry;

[0041] 2) The dried briquette is fed from the top of the carbonization chamber by the charging device, and the carbonization chamber is completely filled with the briquette, and the material surface is higher than the carbonization furnace body by a certain height;

[0042]3) The briquetting material runs downward by gravity in the carbonization chamber, and the carbonization process is completed after passing through the preheating section and the carbonization section. The temperature in the carbonization chamber is 1100 ° C. The heat required...

Embodiment 2

[0053] The technique for producing iron coke of the present invention comprises the following steps:

[0054] 1) Fully mix the pulverized iron ore powder and lignite with an iron grade of 53% and binder, the mass ratio of iron ore powder and lignite is 30:70, and briquetting after mixing, the particle size after briquetting About 30mm, after being dried by the dryer, it is transported to the silo under the tank;

[0055] 2) Put the dried block material obtained above into the carbonization chamber from the top of the carbonization furnace by the furnace top device, and the compact material will completely fill the carbonization chamber and be higher than the top surface of the carbonization furnace by a certain height;

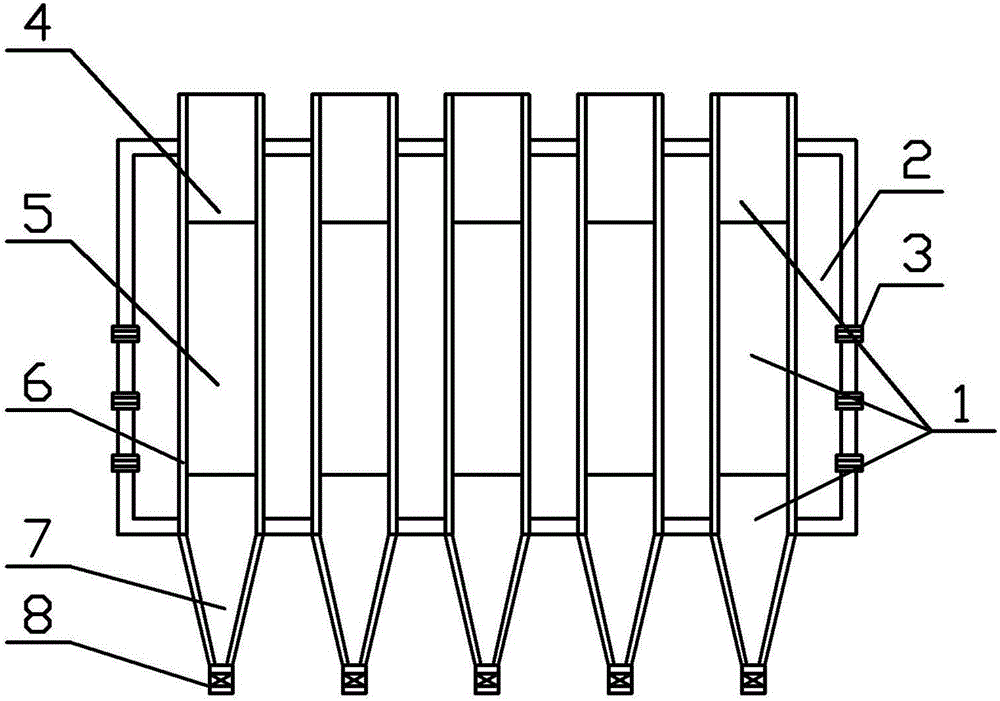

[0056] 3) The preheating section and carbonization section of the carbonization chamber are rectangular, with a width of 300-800mm, a length of 1000-1800mm, and a height of 10000-18000mm;

[0057] 4) The coal gas supplied to the burner through the pipeline an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com