Method used for extracting uranium and niobium from low-grade ore

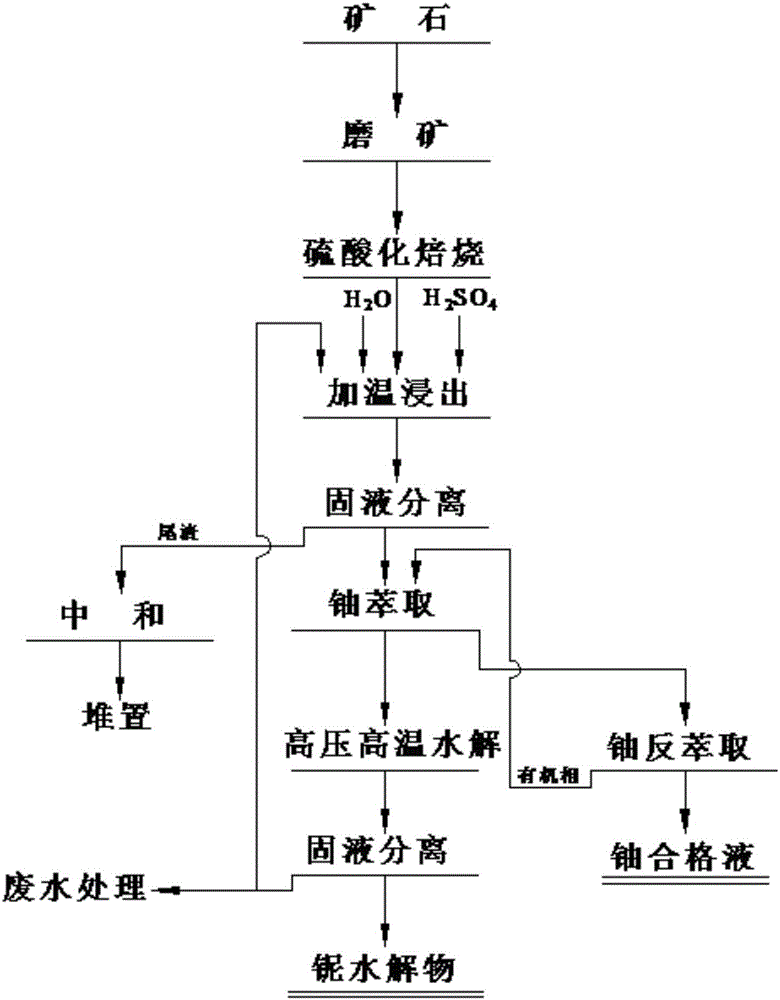

A low-grade, uranium separation technology, applied in the field of hydrometallurgy, to achieve the effects of high uranium and niobium leaching rate, low reagent cost, reduced processing capacity and reagent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A low-grade uranium-containing niobium ore contains 0.425% uranium and 0.359% niobium. The ore is finely ground to -0.030mm and the proportion of ore is 50%. The ore after grinding and concentrated sulfuric acid (98wt%) are ore: concentrated sulfuric acid = 1:0.6 for batching and mixing uniformly, put it in the roaster after 0.5h at room temperature, and roast for 2h at 230℃. After roasting, the clinker is leached with 10wt% sulfuric acid solution, the mass ratio of the leaching liquid is 1.5:1, the leaching temperature is 60°C, and the leaching rate is 1h. The uranium leaching rate is 98.75% and the niobium leaching rate is 86.26%. The leaching pulp is filtered and washed to obtain a filtrate containing uranium and niobium, and the leaching residue is discarded after the washing treatment. The uranium in the organic relative leachate composed of 6% P204 + 5% TBP + 1% P311 + 88% sulfonated kerosene is used for collaborative extraction. The extraction ratio (O / A) is 1.2,...

Embodiment 2

[0029] A low-grade uranium-bearing niobium ore contains uranium content of 0.368%, niobium content of 1.655%, and the ore is ground to -0.025mm, and the ratio of ore is 45%. After grinding the ore and concentrated sulfuric acid (85wt%) according to the mass ratio of the ore: concentrated sulfuric acid = 1:0.8 for batching and mixing uniformly, put it in the roaster at room temperature for 1 hour, and roast at 260°C for 4 hours. After roasting, the clinker is leached with 15wt% sulfuric acid solution, the mass ratio of the leaching liquid is 1.5:1, the leaching temperature is 60℃, the leaching time is 2h, the uranium leaching rate is 98.65%, and the niobium leaching rate is 92.57%. The leaching pulp is filtered and washed to obtain a filtrate containing uranium and niobium, and the leaching residue is discarded after the washing treatment. The uranium in the organic relative leachate composed of 5% P204 + 5% TBP + 2% P311 + 88% sulfonated kerosene is used for collaborative extra...

Embodiment 3

[0031] A low-grade uranium-containing niobium ore contains 0.412% uranium and 0.629% niobium. The ore is finely ground to -0.025mm and the ratio of ore is 60%. The ore after grinding and concentrated sulfuric acid (90wt%) are ore: concentrated sulfuric acid = 1:1 batching, mixing uniformly, placed at room temperature for 1h, then transferred to the roaster, roasted at 280℃ for 3h. After roasting, the clinker was leached with a 10wt% sulfuric acid solution, the leaching liquid solid volume ratio was 2:1, the leaching temperature was 80°C, the leaching time was 1.5h, the uranium leaching rate was 98.52%, and the niobium leaching rate was 92.57%. The leaching pulp is filtered and washed to obtain a filtrate containing uranium and niobium, and the leaching residue is discarded after the washing treatment. The uranium in the organic relative leachate composed of 8% P204 + 5% TBP + 2% P311 + 85% sulfonated kerosene is used for collaborative extraction. The extraction ratio (O / A) is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com