Buffer layer of secondary electron emission film and preparation method thereof

A technology for secondary electron emission and buffer layer, which is applied in electron multiplier details, coating, sputtering and other directions, and can solve the problems of reducing the grain size of magnesium oxide and reducing the secondary electron emission performance of composite films. , to achieve the effect of promoting growth and improving the performance of secondary electron emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

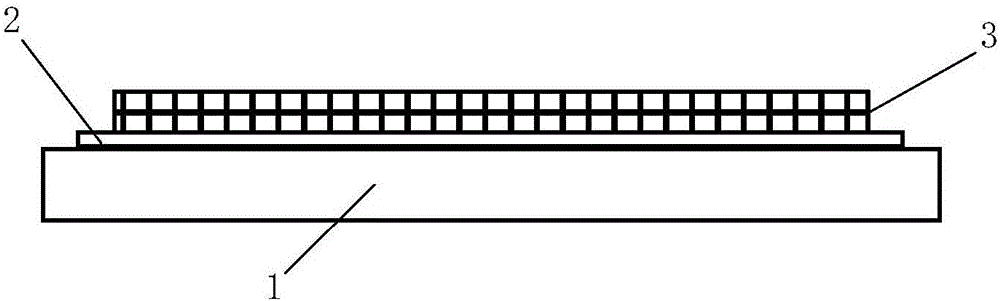

[0025] refer to figure 1 , indicating a secondary electron emission source structure of a magnesium oxide composite thin film doped with metal materials. The secondary electron emission source is composed of a metal base 1 , a nickel oxide buffer layer 2 fabricated on the metal base 1 , and a magnesium oxide layer 3 doped with metal materials fabricated on the nickel oxide buffer layer 2 . The preparation of nickel oxide buffer layer 2 comprises the following steps:

[0026] The metal substrate 1 is cleaned. First, before depositing the nickel oxide buffer layer 2 on the metal substrate 1, the metal substrate 1 is cleaned, the metal substrate 1 is put into a container, acetone is poured into the container to soak the metal substrate 1, and the container is put into ultrasonic cleaning The metal base 1 was ultrasonically cleaned in the machine for 15 minutes, and then the acetone in the container was replaced with ethanol and pure water in turn, and the metal base 1 was ultra...

Embodiment 2

[0029] refer to figure 1 , indicating a secondary electron emission source structure of a magnesium oxide composite thin film doped with metal materials. The secondary electron emission source is composed of a metal base 1 , a nickel oxide buffer layer 2 fabricated on the metal base 1 , and a magnesium oxide layer 3 doped with metal materials fabricated on the nickel oxide buffer layer 2 . The preparation of nickel oxide buffer layer 2 comprises the following steps:

[0030] The metal substrate 1 is cleaned. First, before depositing the nickel oxide buffer layer 2 on the metal substrate 1, the metal substrate 1 is cleaned, the metal substrate 1 is put into a container, acetone is poured into the container to soak the metal substrate 1, and the container is put into ultrasonic cleaning The metal base 1 was ultrasonically cleaned in the machine for 15 minutes, and then the acetone in the container was replaced with ethanol and pure water in turn, and the metal base 1 was ultra...

Embodiment 3

[0033] refer to figure 1 , indicating a secondary electron emission source structure of a magnesium oxide composite thin film doped with metal materials. The secondary electron emission source is composed of a metal base 1 , a nickel oxide buffer layer 2 fabricated on the metal base 1 , and a magnesium oxide layer 3 doped with metal materials fabricated on the nickel oxide buffer layer 2 . The preparation of nickel oxide buffer layer 2 comprises the following steps:

[0034]The metal substrate 1 is cleaned. First, before depositing the nickel oxide buffer layer 2 on the metal substrate 1, the metal substrate 1 is cleaned, the metal substrate 1 is put into a container, acetone is poured into the container to soak the metal substrate 1, and the container is put into ultrasonic cleaning The metal base 1 was ultrasonically cleaned in the machine for 15 minutes, and then the acetone in the container was replaced with ethanol and pure water in turn, and the metal base 1 was ultras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com