Method for preparing metallic-matrix ceramic coating by using laser cladding assisted by heat, sound and magnetic complex energy field

A composite energy field and auxiliary laser technology, applied in the direction of metal material coating process, coating, etc., to achieve the effects of microstructure refinement and homogenization, time extension, and improved effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

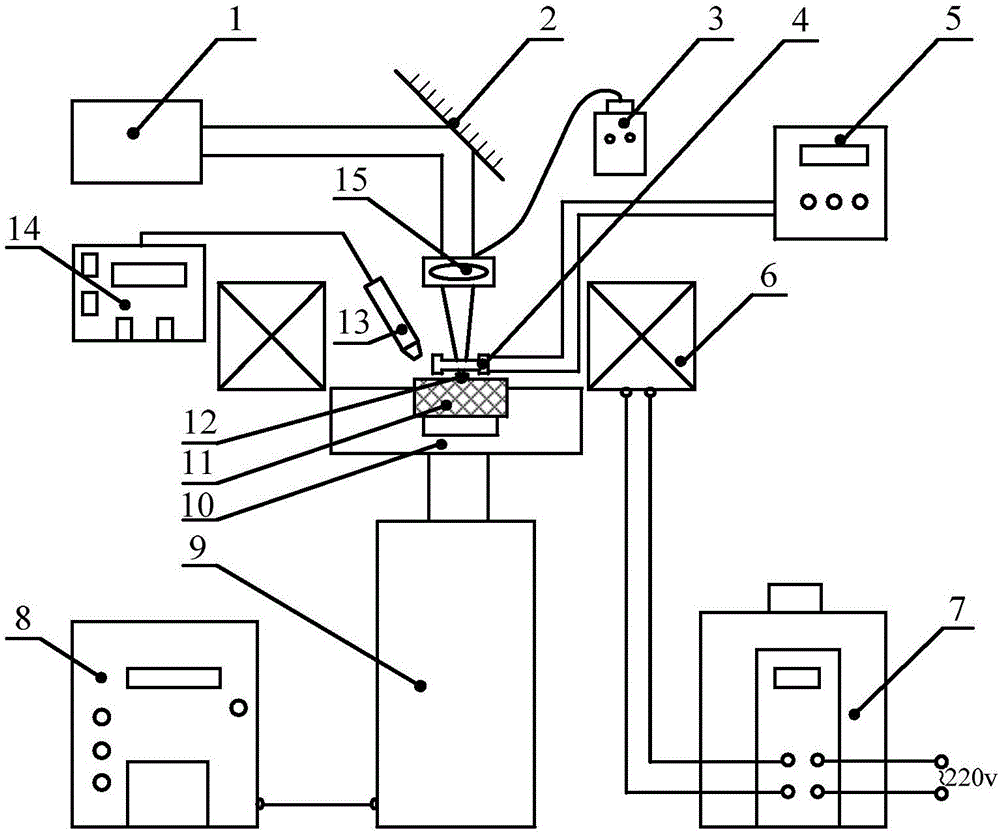

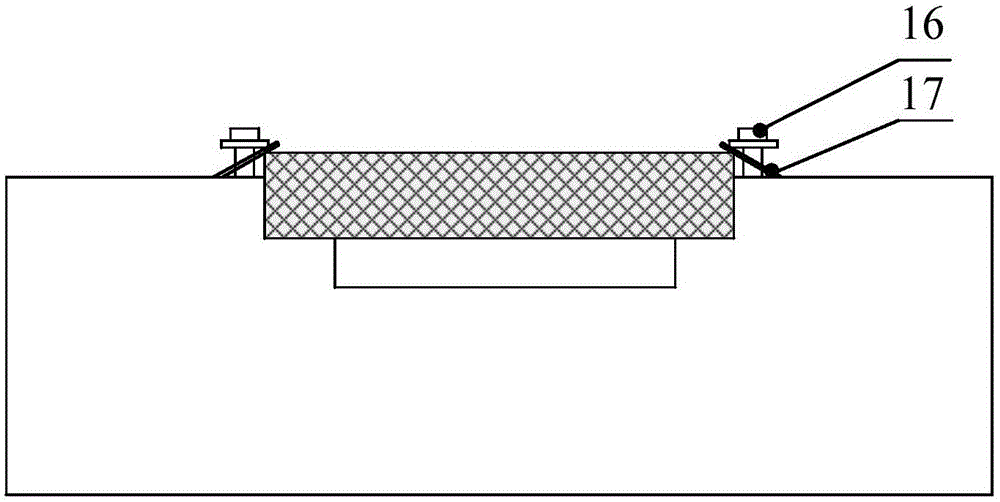

[0033] 1) Install and fix the mold steel after grinding, cleaning and drying on the fixture 10; as figure 2 As shown, the substrate 11 is clamped and positioned by four screw rods 16 through the gasket 17;

[0034] 2) Put the Ni+35% WC alloy powder with a good ratio into a ball mill for 8 hours of mixing, and put the powder into the coaxial powder feeder 3 after stirring evenly;

[0035] 3) The distance between the induction heating coil 4 and the base material 11 is set to 1mm, and the induction heating power supply 5 is adjusted to make the surface temperature of the base material 11 reach 280°C;

[0036] 4) Use the industrial online infrared thermometer 13 to monitor the surface temperature of the substrate 11, and observe the temperature change of the substrate 11 surface in real time through the digital display control instrument 14. After the surface temperature of the substrate 11 reaches the predetermined temperature, turn on the electromagnetic-ultrasonic The compos...

Embodiment 2

[0040] 1) Install and fix the polished, cleaned and dried nickel-based superalloy on the fixture 10;

[0041] 2) Put the Co+35% TiC alloy powder with a good ratio into a ball mill for 12 hours of mixing, and put the powder into the coaxial powder feeder 3 after stirring evenly;

[0042] 3) The distance between the induction heating coil 4 and the base material 11 is set to 5mm, and the induction heating power supply 5 is adjusted to make the surface temperature of the base material 11 reach 800°C;

[0043] 4) Use the industrial online infrared thermometer 13 to monitor the surface temperature of the substrate 11, and observe the temperature change of the substrate 11 surface in real time through the digital display control instrument 14. After the surface temperature of the substrate 11 reaches the predetermined temperature, turn on the electromagnetic-ultrasonic The composite energy field device realizes the multi-field coupling coordination of induction preheating, electroma...

Embodiment 3

[0047] 1) installing and fixing the polished, cleaned and dried titanium alloy on the fixture 10;

[0048] 2) Put Fe+50% SiC alloy powder with a good ratio into a ball mill for 10 hours of mixing, and put the powder into the coaxial powder feeder 3 after stirring evenly;

[0049] 3) The distance between the induction heating coil 4 and the base material 11 is set to 3mm, and the induction heating power supply 5 is adjusted to make the surface temperature of the base material 11 reach 450°C;

[0050] 4) Use the industrial online infrared thermometer 13 to monitor the surface temperature of the substrate 11, and observe the temperature change of the substrate 11 surface in real time through the digital display control instrument 14. After the surface temperature of the substrate 11 reaches the predetermined temperature, turn on the electromagnetic-ultrasonic The composite energy field device realizes the multi-field coupling coordination of induction preheating, electromagnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com