Coral sand solidification method

A curing method and technology of coral sand, applied in construction, infrastructure engineering, soil protection and other directions, can solve problems such as large porosity, loss of active coral sand, and making ends meet, and achieve enhanced crack resistance and impermeability, The effect of maintaining underwater topography and high impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

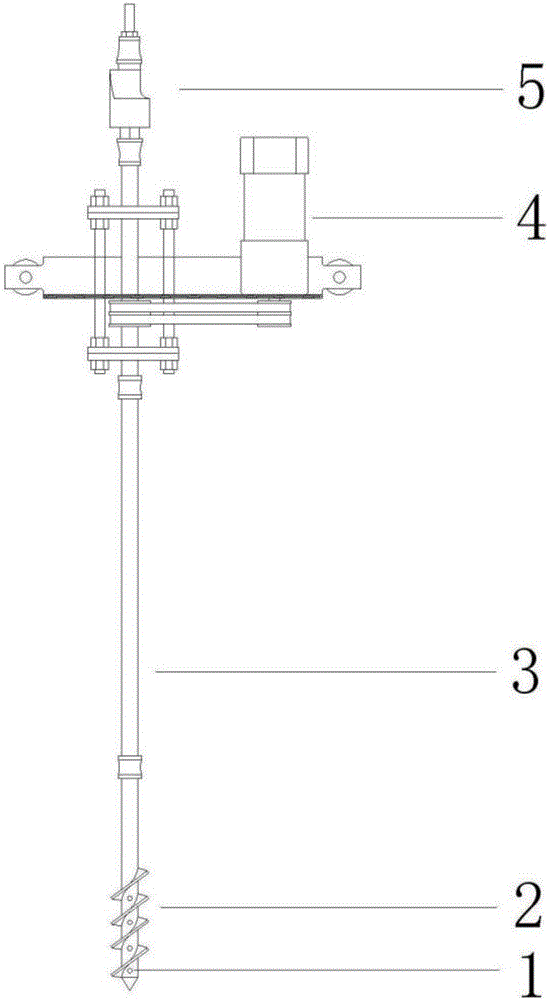

Image

Examples

Embodiment 1

[0032] A kind of coral sand curing method, comprises the following steps:

[0033] S1. Drilling the above-mentioned high-pressure jet grouting device to a preset depth, the preset depth is 0.5-2 meters.

[0034] S2. Start the mortar pump valve, squeeze the prepared cement slurry through the mortar pump, transport the cement slurry to the drill pipe, and squeeze and grout the coral sand through the drill bit and the grouting hole. Rotate within the range of 0.5-2 meters and continue to lift and lower the drill pipe, and inject grout while rotating the drill bit, which is conducive to fully mixing the coral sand and cement slurry at this place.

[0035] S3. After the rotary spraying and stirring work is completed, the drill pipe is lifted out, and the coral sand concrete can be obtained after curing.

[0036] The invention can forcibly infiltrate special cement slurry into coral sand through a high-pressure rotary jet grouting device to form coral sand concrete, thereby achievi...

Embodiment 2

[0038] A kind of coral sand curing method, comprises the following steps:

[0039] S1. Drill the above-mentioned high-pressure jet grouting device to a first preset depth, and the first preset depth is 1-2 meters.

[0040] S2. Start the valve of the mortar pump, pass the prepared cement slurry through the extrusion of the mortar pump, transport the cement slurry to the drill pipe, and perform extrusion grouting to the coral sand through the drill bit and the grouting hole. Rotate and continuously lift and lower the drill pipe at a depth of 1 to 2 meters, and inject grout while rotating the drill bit, which is conducive to fully mixing the coral sand and cement slurry there.

[0041] S3. Lifting the drill bit to a second preset depth, the second preset depth is closer to the ground than the first preset depth, and the second preset depth is 0.5-1 meter.

[0042] S4. Rotate and continuously lift and lower the drill pipe within the second preset depth of 0.5 to 1 meter, and inje...

Embodiment 3

[0046] A method for curing coral sand, comprising the following steps:

[0047] S1. Drill the above-mentioned high-pressure rotary jet grouting device to a first preset depth, where the first preset depth is 1-2 meters.

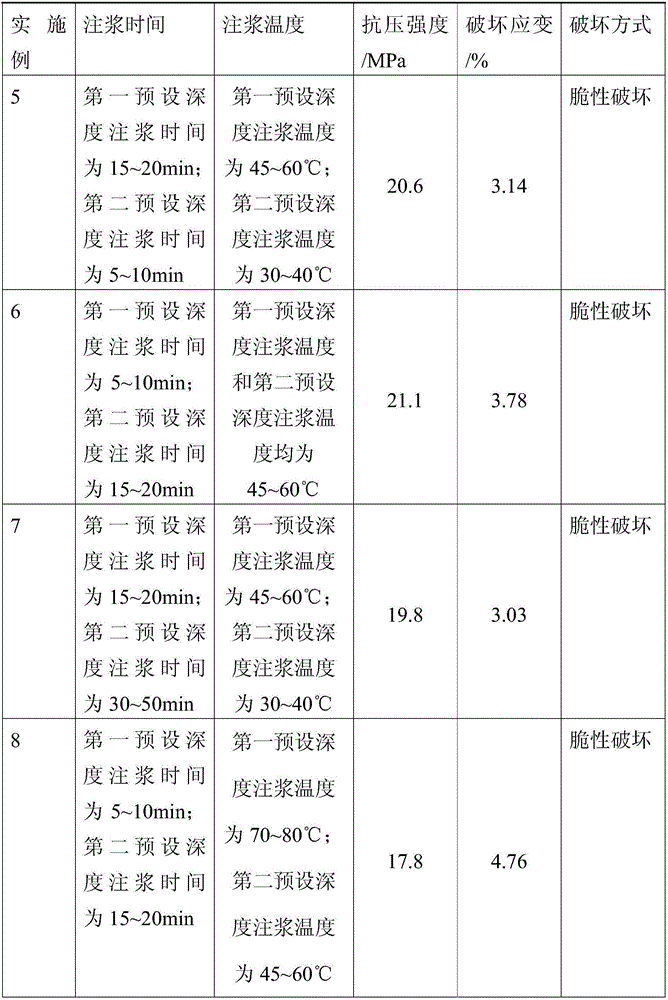

[0048] S2. Start the mortar pump valve, squeeze the prepared cement slurry through the mortar pump, transport the cement slurry to the drill pipe, and squeeze the coral sand through the drill bit and the grouting hole. The drill pipe is set to rotate within a depth of 1 to 2 meters and continuously raise and lower the drill pipe, and the drill bit is rotated while grouting, which is conducive to fully mixing the coral sand and the cement slurry. In order to improve the mixing effect at a deeper position from the ground, In this step, the grouting time should be shorter and the temperature should be higher, preferably the grouting time is 5-10 minutes, and the slurry temperature is 45-60°C.

[0049] S3. Raise the drill bit to a second preset depth, where the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com