Light filter material for aerated biological filter tank and preparation method thereof

A technology of biological aerated filter and lightweight filter material, which is applied in the fields of chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., and can solve the problem of film-hanging speed, hanging modulus film and filter material tightness Insufficient, COD and ammonia nitrogen removal rate needs to be improved, unfavorable ecological balance and effective utilization of resources, etc., to achieve the effect of favorable treatment, fast and convenient backwashing, and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

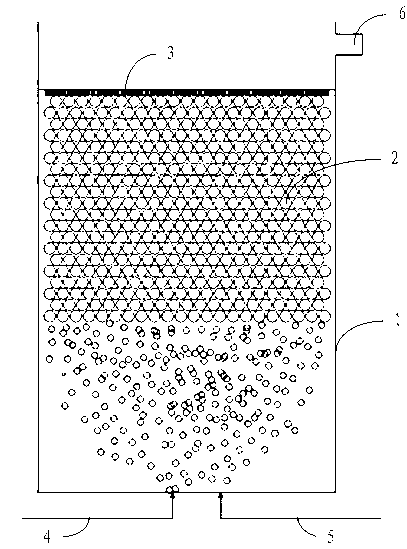

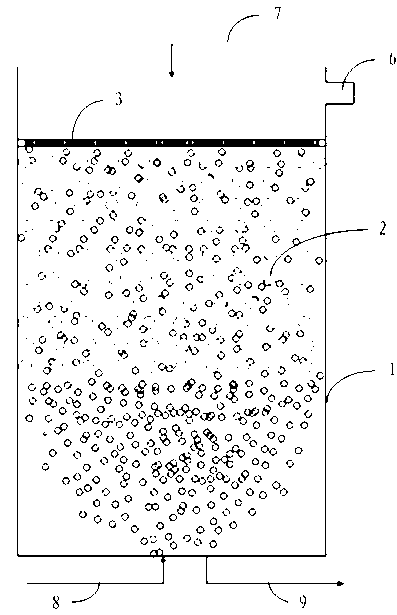

Method used

Image

Examples

Embodiment 1

[0024] Polystyrene (PS) is foamed and injected into a spherical filter material, with a particle size of 3-4mm and an apparent density of 0.14g / cm 3 . The apparent density can be measured by the following method: Take a jar with a volume of 1L and dry it to constant weight, and weigh it as W 1 ; Place the filter material to be tested in a desiccator and dry it at 23°C for more than 24 hours, then fill the jar with the dry filter material and weigh it as W 2 ; Then fill the jar with water, wipe off the water on the outer wall of the jar, and weigh it as W 3 ; Pour out all the filter material in the jar, fill it with water and dry the outer wall, and weigh it as W 4 . The apparent density of the filter material is calculated as follows: [(W 2 -W 1 ) / (W 4 -W 3 +W 2 -W 1 )]·1g / cm 3 .

[0025] The obtained filter material and common high-resolution material filter material are carried out hydrophilic test, and the results are shown in Table 1 and Table 2:

[0026]

...

Embodiment 2

[0034] Polystyrene (PS) is foamed and injected into a spherical filter material, with a particle size of 3-4mm and an apparent density of 0.085g / cm 3 . The filter material is irradiated with ultraviolet light with a wavelength of 200nm-400nm for 1.7 hours, and the irradiation temperature is 65°C-70°C.

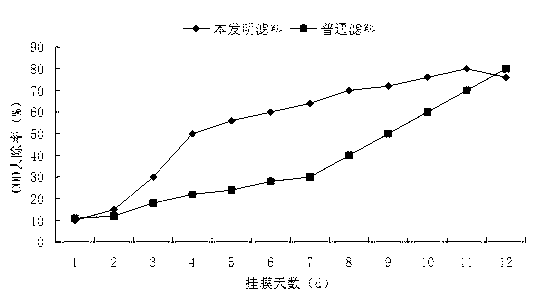

[0035] The prepared filter material is used in the upflow biological aerated filter for domestic sewage treatment. Under the condition that the air-water ratio is (4-5): 1 and the hydraulic retention time is 1.5h, it is comparable to the ordinary polymer filter. Compared with the sewage treatment effect of raw materials, the results are as follows image 3 , Figure 4 As shown, it can be seen from the figure that the filter material of the present invention has a better COD removal rate during different film-hanging periods, and the filter material of the present invention has a better ammonia nitrogen removal rate after 3 days of film-hanging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com