A system for improving the recovery rate of rare earths and a liquid collection system for rare earth mines using the same

A recovery rate and rare earth technology, applied in the improvement of process efficiency, surface mining, underground mining and other directions, can solve the problems of lower concentration, affecting the recovery rate of rare earth, and high impurity content, and achieve the goal of increasing the concentration, increasing the recovery rate of rare earth, reducing the The effect of impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

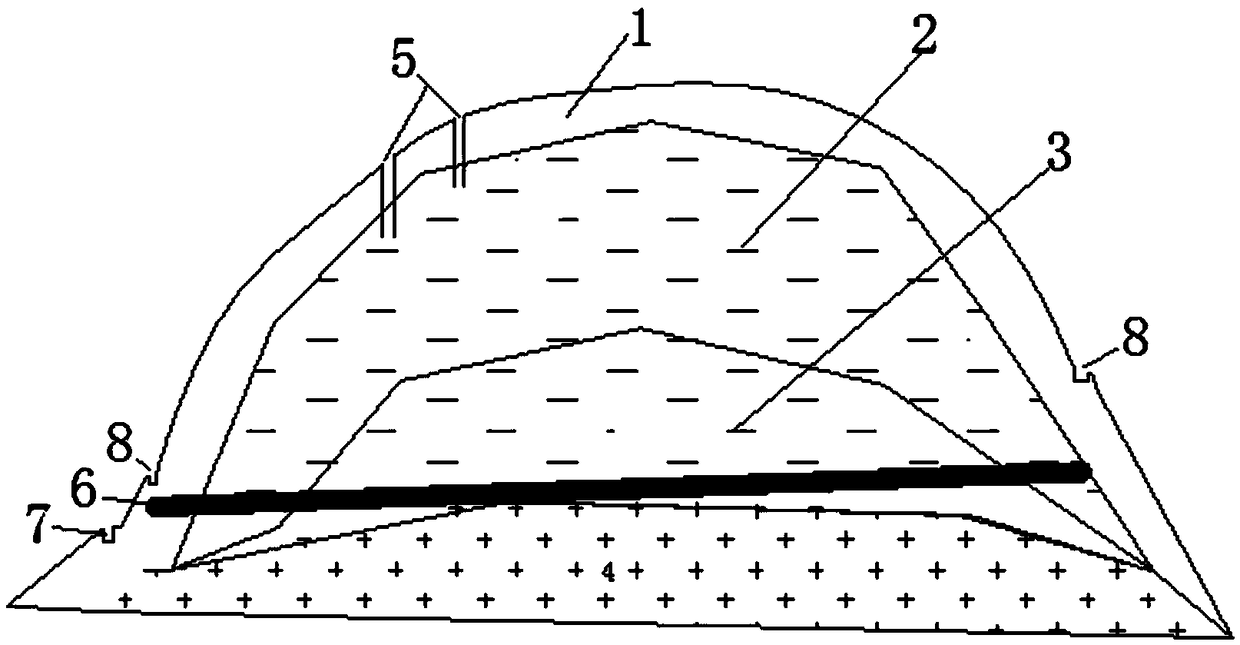

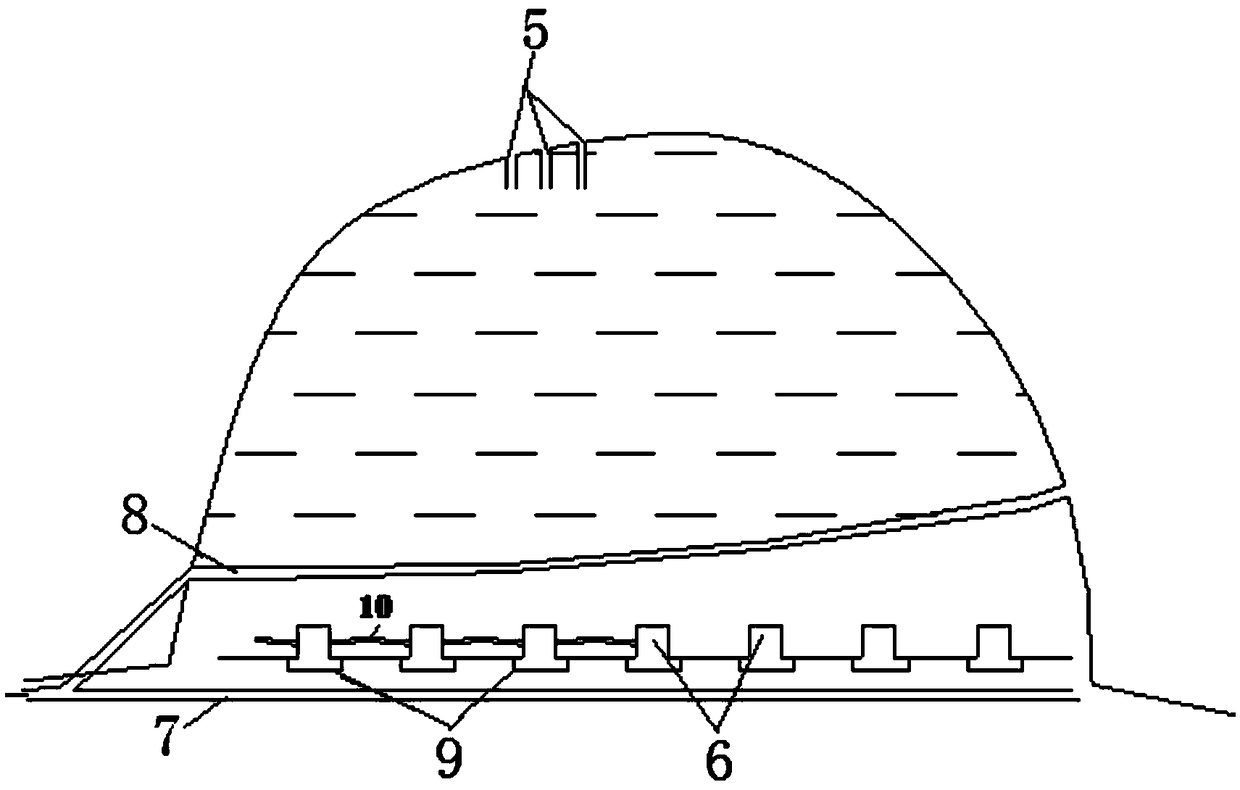

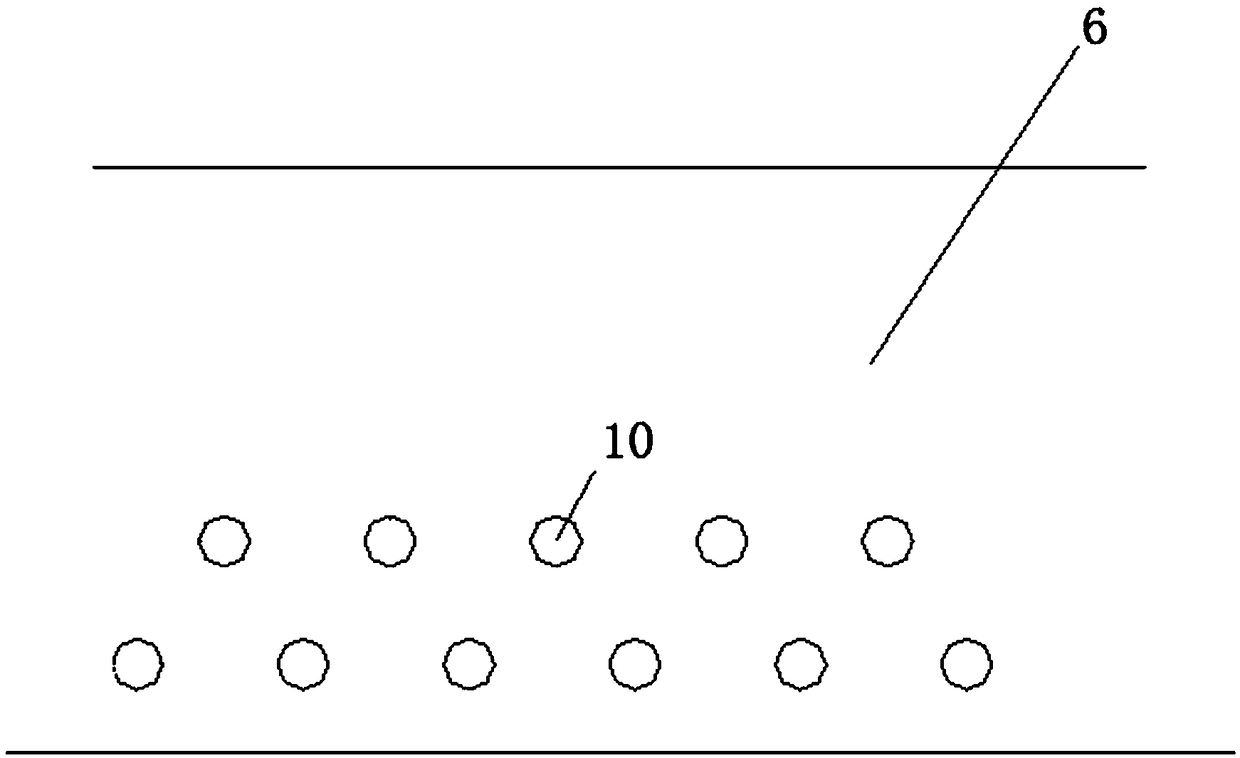

[0038] This embodiment provides a system for improving the recovery rate of rare earths, such as figure 1 and 2 As shown, the system includes a mountain-surrounding water-avoidance ditch 8 arranged above the liquid collection roadway 6 along the lower part of the regolith 2 for intercepting and separating non-rare earth leachate.

[0039] In the above-mentioned system, by setting the ditch 8 around the mountain, the non-rare earth leachate, such as rainwater, can be intercepted and separated, so as to prevent the non-rare earth leachate from entering the liquid collection roadway 6 and mixing with the rare earth leachate. Compared with the prior art, this operation increases the concentration of the rare earth leach solution, reduces the impurity content in it, and reduces the difficulty of subsequent rare earth separation from the rare earth leach solution. Correspondingly, it is also conducive to improving the recovery rate of rare earth.

[0040] In order to further reduce...

Embodiment 2

[0058] This embodiment provides a liquid collection system for rare earth mines, such as figure 1 and 2 As shown, it includes a liquid collection roadway 6 placed between the weathered layer 2 and the bedrock 4, and a liquid injection hole 5 arranged above the weathered layer 2; it also includes the system for improving the recovery rate of rare earths in Example 1.

[0059] Through the liquid collection system of the above-mentioned rare earth mines, a clean-up and diversion system is established on the rare earth mines, rainwater and other non-rare earth leaching liquids are collected through the ditch 8 around the mountain, and the rare earth mines are separated from the streams and ponds through the flood drainage ditch 7 to avoid its impact The rare earth leaching solution and the non-rare earth leaching solution collected by the surrounding mountain avoidance ditch 8 enter the flood discharge ditch 7 and are discharged to the outside, realizing the diversion of cleaning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com