Tapered fusing cladding power filter

A filter and power technology, applied in clad optical fibers, multi-layer core/clad optical fibers, instruments, etc., can solve the problems of optical glue temperature rise, affecting the properties of optical glue, damage, etc., to improve the filtering effect , Improve the effect of heat-resistant temperature and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

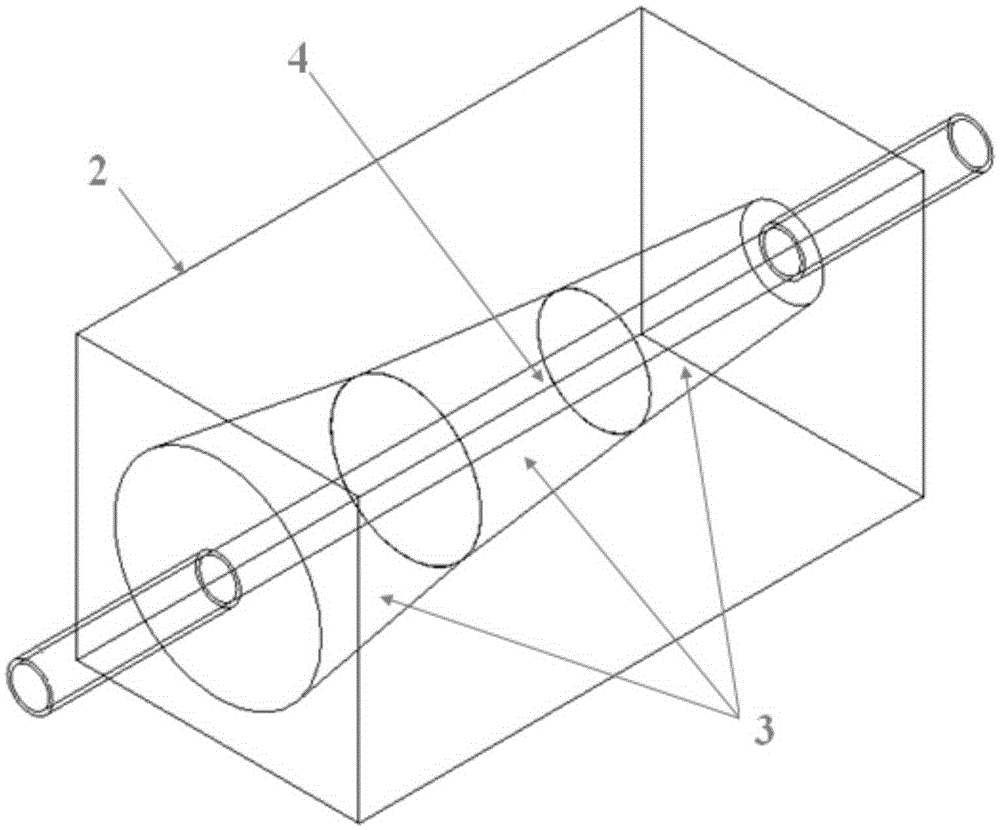

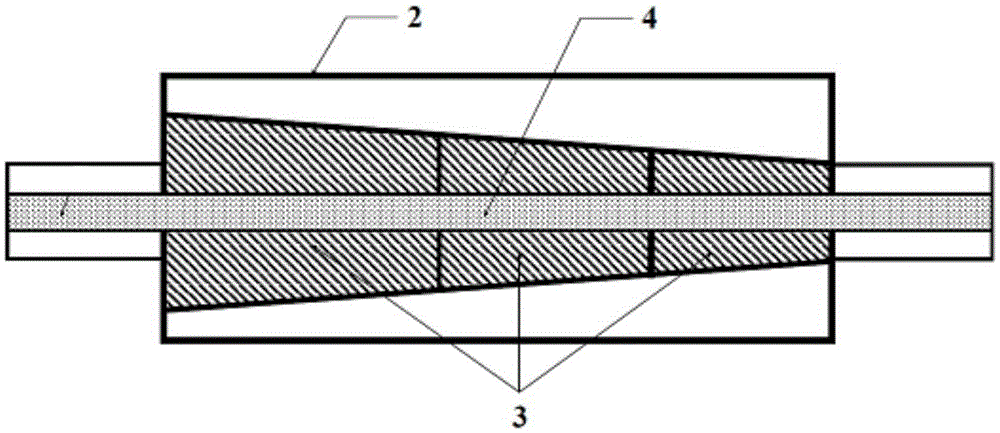

[0012] Such as figure 1 and figure 2 As shown, a tapered fused cladding power filter of the present invention includes a section of optical fiber 4 that removes the outer cladding and coating layer, and connects and solidifies the optical glass layer 3 on the optical fiber 4; the optical glass layer 3 is a tapered body, The outer diameter of the cone gradually shrinks along the propagation direction of light in the optical fiber 4, and the cone angle of the cone is greater than 10°; the refractive index of the optical glass layer 3 is greater than that of the removed outer cladding and coating layer; the optical fiber 4 and the optical glass layer 3 All are sealed in the metal casing 2, and a cooling water channel is arranged in the metal casing 2.

[0013] Such as figure 1 As shown, the optical glass layer 3 of the tapered fused cladding power filter is divided into N segments, N≥2, and along the light propagation direction in the optical fiber 4, the refractive index of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com