Die-casting mould pouring parameterization design system and method

A technology of parametric design and die-casting mold, applied in the field of die-casting mold industry, can solve problems such as incompleteness, low efficiency, and inability to unify design methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

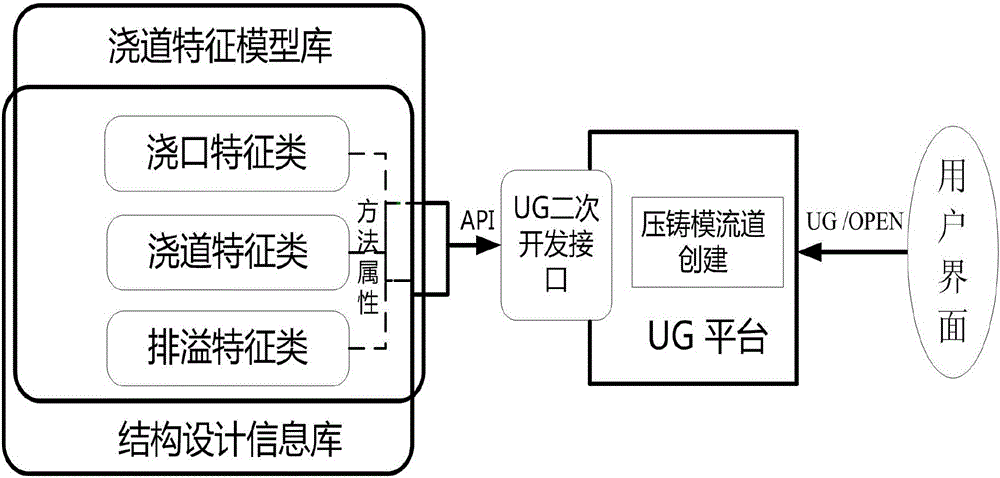

[0117] In the specific implementation, the encapsulation of the sprue feature unit is formed into the sprue feature class through the object-oriented programming method, which includes the fusion of digital information and design information of the mold sprue geometric elements. The communication between these encapsulated feature classes is carried out by setting the method attributes of each feature class, thus forming a sprue feature model library and structural design library with a certain level of hierarchy and system; and the communication with the outside uses UI BLOCK The human-computer interaction menu tools and application programming interface API (Application Programming Interface) created by STYLER realize the communication between the runner characteristic unit and the UG platform, and complete the instantiation expression of the die-casting mold runner design information. The communication process of sprue feature class is as follows: figure 1 shown.

[0118] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com