Automatic line body for front-section printing of touch screen

A touch screen, automatic technology, applied in printing, printing machines, printing processes, etc., can solve the problems of increased risk of product scratches, inability to make breakthroughs in efficiency and production capacity, and scratches on the outside of the sensor, so as to reduce personnel intervention and contact The frequency, high installation flexibility and adaptability, the effect of reducing the chance of being scratched and collided

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

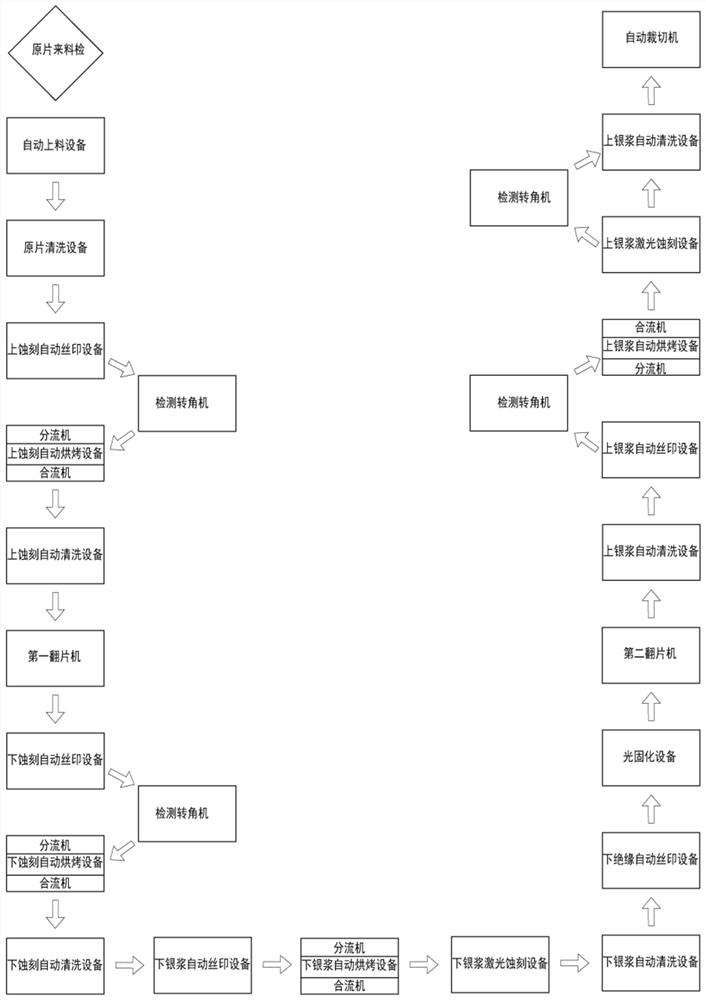

[0033] like figure 1 As shown, the front-end printing automation line body of the touch screen of the present invention includes automatic feeding equipment, original film cleaning equipment, automatic screen printing equipment for etching on the silk screen, and automatic screen printing equipment for IPQC sampling inspection products that are sequentially connected and directly installed on the floor of the factory building. Screen printing effect detection corner machine, splitter for side-by-side transmission of products to the upper etching baking machine, upper etching automatic baking equipment, confluence machine for realizing product delivery one by one, upper etching automatic cleaning for cleaning upper etching Equipment, the first film turning machine for flipping products, the automatic screen printing equipment for bottom etching for silk screen printing, the detection corner machine for IPQC sampling inspection of product silk screen printing effects, the splitte...

Embodiment 2

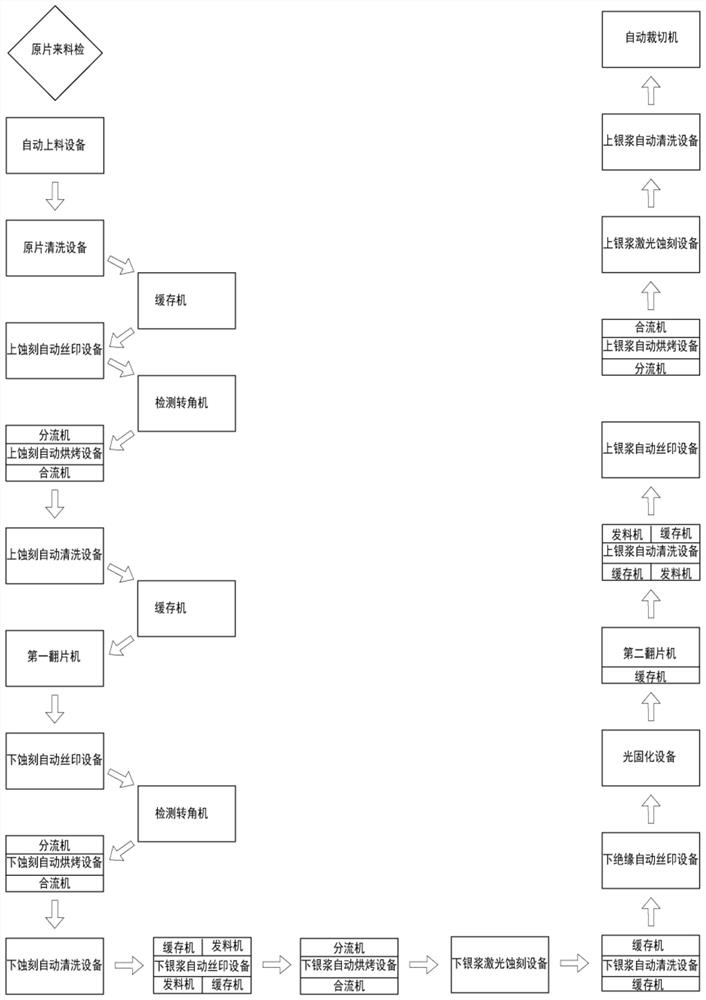

[0036] like figure 2As shown, the touch screen front-end printing automation line body of the present invention includes automatic feeding equipment, original film cleaning equipment, buffer machine, automatic screen printing equipment for etching on the silk screen, and automatic screen printing equipment for etching on the screen printing. IPQC inspection corner machine for sampling silk screen printing effect of products, diverter machine for side-by-side transmission of products to the upper etching baking machine, automatic baking equipment for upper etching, confluence machine for transferring products one by one, and upper etching machine for cleaning Etching automatic cleaning equipment, a buffer machine for receiving 40 pieces each time, the first film turning machine for flipping products, automatic silk screen printing equipment for bottom etching for silk screen printing, and a corner machine for testing the silk screen effect of IPQC sampling products, Diverter f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com