Preparation method of hydrotreating catalyst

A hydrogenation treatment and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of affecting the catalyst's reactivity and affecting the high dispersion of active components And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

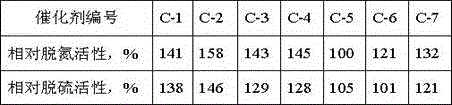

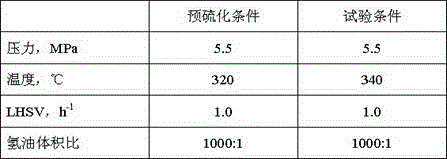

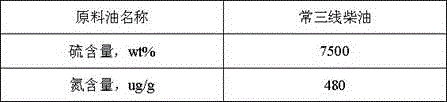

Examples

Embodiment 1

[0019] Example 1 (preparation of alumina carrier)

[0020] Weigh 200 grams of aluminum hydroxide dry rubber powder, 100 grams of SB powder, add 4 grams of kale powder and 4 grams of citric acid, mix well and add acidic solution, the concentration of nitric acid in the acidic solution is 2wt%, and the rest is distilled water. Roll for 15-25 minutes, extrude with a clover orifice plate with a diameter of 1.7mm, dry at 120°C for 12 hours, and bake at 550°C for 3 hours to obtain an alumina carrier, namely Z-1, whose properties are as follows: the pore volume is 0.72ml / g, the specific surface area is 342m 2 / g.

Embodiment 2

[0022] Weigh an appropriate amount of carrier Z-1, and impregnate carrier Z-1 with an impregnating solution containing Mo, Ni, P, 2-amino-1,3 propanediol in equal volume. The composition of the impregnating solution is MoO 3 The content of NiO is 88.5g / 100ml, the content of NiO is 15 g / 100ml, the content of P is 2.3g / 100ml, and the molar ratio of the amount of 2-amino-1,3 propanediol to Ni atoms in the final catalyst is 0.5:1. Microwave treatment was carried out after impregnation. The power of microwave was 8 W / g, and the treatment time was 15 minutes. The sample after microwave treatment was dried in air atmosphere at 180°C for 3 hours to obtain catalyst C-1. The catalyst composition was 23%MoO 3 , 3.6%NiO, 1.5%p.

Embodiment 3

[0024] Weigh an appropriate amount of catalyst carrier Z-1, impregnate the carrier Z-1 with an impregnation solution containing Mo, Ni, P, 2-amino-1,3 propanediol in equal volume, the composition of the impregnation solution is MoO 3The content of NiO is 89.5g / 100ml, the content of NiO is 15 g / 100ml, the content of P is 2.5g / 100ml, and the molar ratio of the amount of 2-amino-1,3 propanediol to the Ni content in the final catalyst is 1:1. The impregnated sample was subjected to microwave treatment. The power of the microwave was 10 W / g, and the treatment time was 15 minutes. The sample after microwave treatment was dried in an air atmosphere at 150°C for 1 hour to obtain catalyst C-2. The catalyst composition was 23%MoO 3 , 3.6%NiO, 1.63%p.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com