Magnesium fluoride catalyst and its preparation method and use

A catalyst, magnesium fluoride technology, applied in physical/chemical process catalysts, dehydrohalogenation preparation, chemical instruments and methods, etc., can solve problems such as the application mode and effect of magnesium fluoride catalyst are not given, and achieve safety High, stable, suitable pore size and pore volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

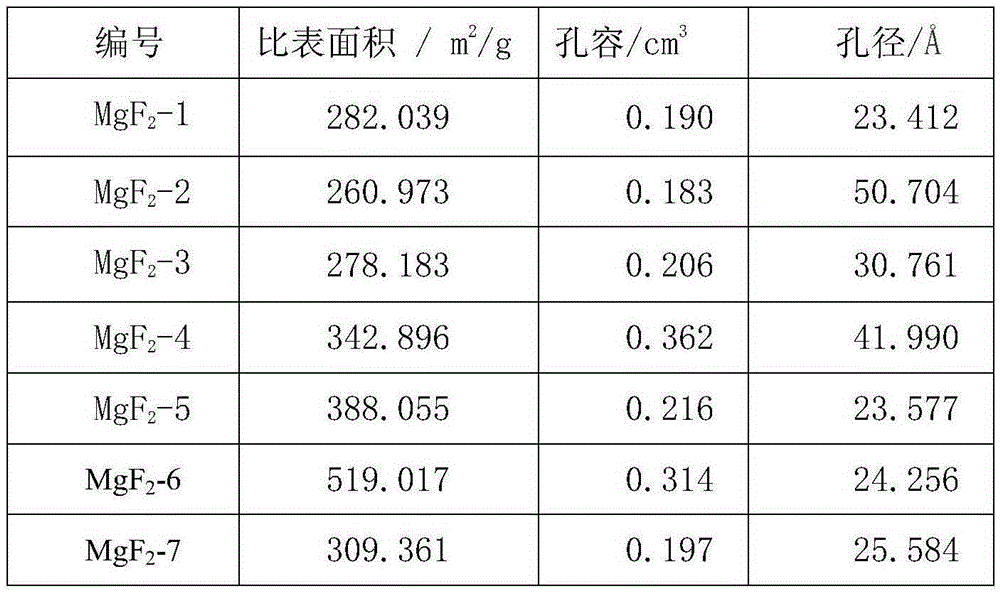

Embodiment 1

[0038] Dissolve 82.68g of magnesium ethylate in 570ml of isopropanol, stir to make it evenly mixed, and form a magnesium-alcohol solution. At room temperature, dissolve 31.79g of anhydrous HF in HF-Et 2 O (ether) solution was added to the magnesium-alcohol solution, stirred vigorously, and stopped stirring after 20 hours of reaction. Use a vacuum rotary evaporator to remove the volatile components in the product, put it in a vacuum oven to dry, and then obtain the catalyst precursor, which is denoted as MgF 2 -1.

Embodiment 2

[0040] Dissolve 82.68g of magnesium isopropoxide in 600ml of toluene, stir to make it evenly mixed, and form a magnesium-benzene solution. At room temperature, dissolve 25.53g of anhydrous HF in HF-Et 2 O solution was added to the magnesium-benzene solution, stirred vigorously, and stopped stirring after 20 hours of reaction. Use a vacuum rotary evaporator to remove the volatile components in the product, and then dry it in a vacuum oven to obtain the catalyst precursor, which is denoted as MgF 2 -2.

Embodiment 3

[0042] Dissolve 82.68g of magnesium acetate in 600ml of methanol, stir to make it evenly mixed, and form a magnesium-alcohol solution. At room temperature, dissolve 25.55 g of anhydrous HF in HF-CH 3 Add OH (methanol) solution into the magnesium alcohol solution, stir vigorously, and stop stirring after 20 hours of reaction. Use a vacuum rotary evaporator to remove the volatile components in the product, and then dry it in a vacuum oven to obtain the catalyst precursor, which is denoted as MgF 2 -3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com