Iron carbon and bentonite sodium alginate gel catalyst and preparation method and application thereof

A technology of gel catalyst and sodium alginate, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., which can solve the problem of white spots, high proportion of tetrahydrofuran generation, and the impact of Problems such as the appearance of shoe uppers, to achieve the effects of cost reduction, high efficiency, and small release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Dissolve 2-4g of bentonite in deionized water (100mL of deionized water), then add 0.2-1g of activated carbon powder, and finally add 2-5g of sodium alginate and stir until dissolved;

[0033] (2) Place the material obtained in step (1) under mechanical stirring for 6-10 hours;

[0034] (3) Add 2 to 10 g of iron powder to the material obtained in step (2), and then stir for 5 to 30 minutes;

[0035] (4) preparation concentration is the calcium chloride solution of 4~8wt%;

[0036] (5) Pour the material of step (3) gained in the funnel, then the calcium chloride solution of step (4) is placed on the magnetic stirrer, then let the material of step (3) gained in the above-mentioned calcium chloride solution Gel into gel balls and soak for 0.5-2 hours;

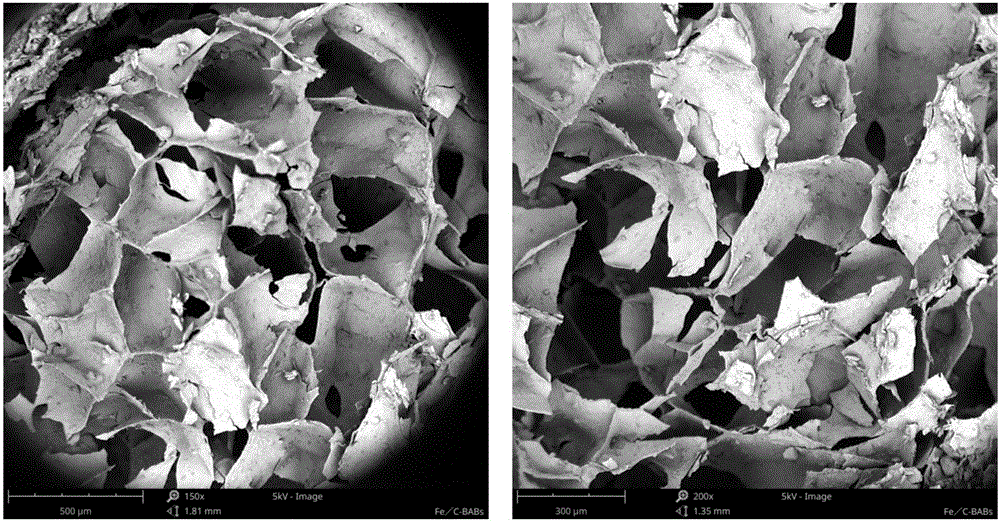

[0037] (6) Wash the gel beads obtained in step (5) with deionized water, seal them in water or store them in vacuum for later use, and obtain the following: figure 1 and figure 2 The iron-carbon-bentonite sodium al...

Embodiment 2

[0039] Preparation of iron-carbon-bentonite sodium alginate gel catalyst (beads, MABs):

[0040] (1) Dissolve 2g of bentonite in deionized water (100mL of deionized water), then add 0.2g of activated carbon powder, and finally add 2g of sodium alginate and stir until dissolved;

[0041] (2) Place the material obtained in step (1) under mechanical stirring for 6-10 hours;

[0042] (3) Add 2 g of iron powder to the material obtained in step (2), then stir for 5 to 30 minutes;

[0043] (4) preparation concentration is the calcium chloride solution of 4wt%;

[0044] (5) Pour the material of step (3) gained in the funnel, then the calcium chloride solution of step (4) is placed on the magnetic stirrer, then let the material of step (3) gained in the above-mentioned calcium chloride solution Gel into gel balls and soak for 0.5-2 hours;

[0045] (6) Wash the gel beads obtained in step (5) with deionized water, and then set aside.

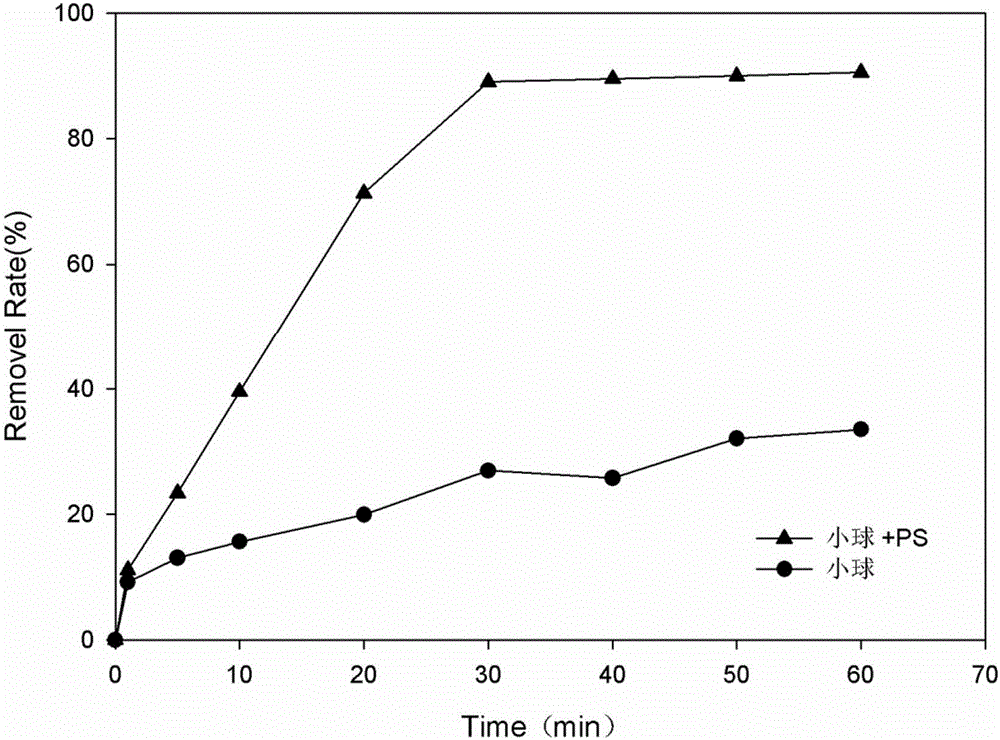

[0046] Add 100mL of reactive black 5 (RBK5) solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com