Cyclone separator of oblique side-cutting cyclone water inlet structure

A technology of cyclone separator and oblique side, which is applied in the field of cyclone separator with oblique side cut swirl flow inlet structure, can solve the problems of small centripetal force of feed water, low water quality, oil, sedimentation, water can not be completely separated, etc., to achieve cyclone The effect of long flow time and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

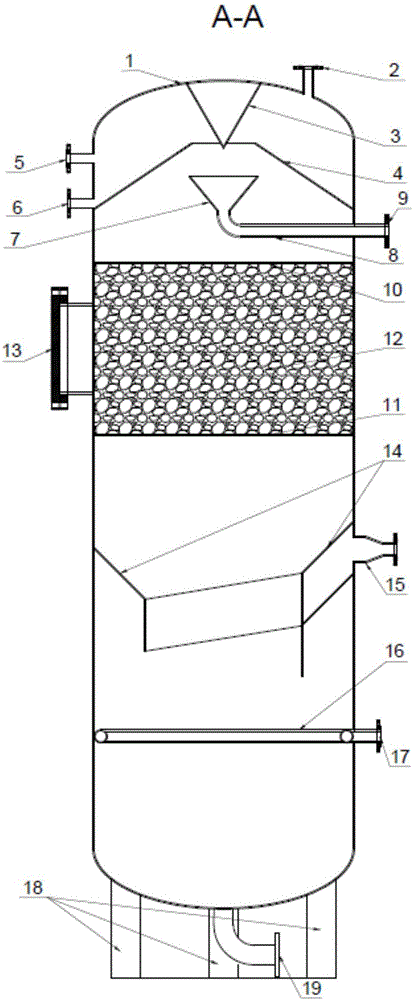

[0029] See details figure 1 , figure 2 , a spiral diversion rapid sedimentation and separation device provided by the present invention, comprising a tank body 1, an overflow port 2, a diverter cone 3, a diverter cap 4, an oil discharge port 5, a slag discharge port 6, a water collection port 7, and a drain pipe 8 , water outlet 9, upper filter plate 10, filler 11, lower filter plate 12, manhole 13, spiral diversion groove 14, water inlet 15, backwash water pipe 16, backwash inlet 17, support foot 18, sewage outlet 19.

[0030] The tank body 1 is installed on the support feet 18, the outer wall of the tank body 1 is provided with a water inlet 15 in the middle, a sewage outlet 19 in the lower part, a manhole 13 in the upper middle part, a water outlet 9, a slag discharge port 6, an oil discharge port 5 and a water outlet in the upper part. An overflow port 2; a diverter cone 3 is arranged on the top of the inner cavity of the tank body 1, a diverter cap 4 is arranged under t...

Embodiment approach

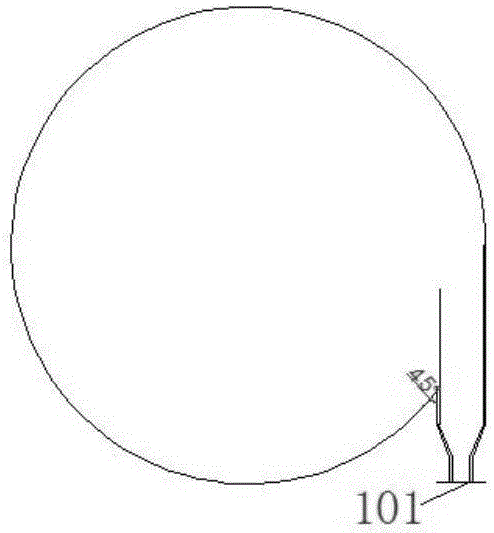

[0034] The implementation mode of this example: the waste water containing oil and organic impurities enters the spiral diversion tank 14 from the water inlet pipe 101, and uses inertia and centripetal force to swirl in the tank. Because the densities of organic impurities, water, and oil are different, three-phase separation is finally formed. Sewage oil floats up and is collected by the oil collection port, and machine miscellaneous sinks are discharged into the sludge tank from the sewage discharge port, and the clear water layer in the middle flows out from the outlet of the cyclone.

[0035] The advantage of this embodiment:

[0036] (1) Low manufacturing cost;

[0037] (2) Low manufacturing difficulty;

[0038] (3) Low installation difficulty.

Embodiment 2

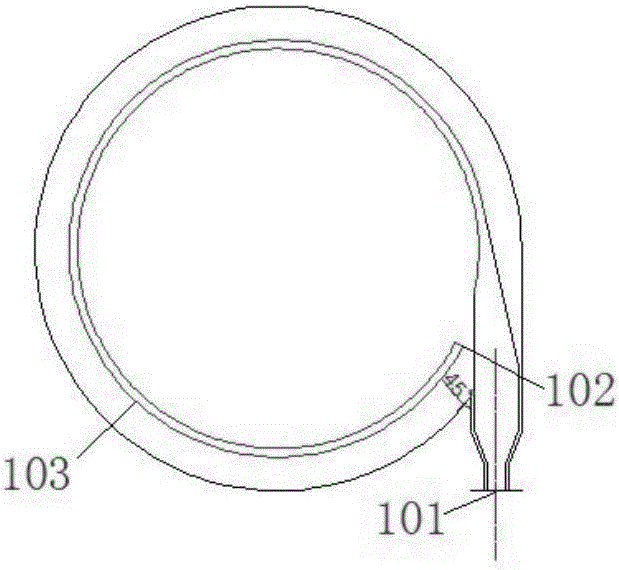

[0040] please see image 3 , a cyclone separator with oblique side-cut swirl water inlet structure provided by the present invention, the structure is similar to that of embodiment 1, the difference is that a water distribution pipe 103 is arranged in the spiral diversion groove 14, and the water inlet of the water inlet pipe 101 passes through After the water distribution pipe 103, it flows out through the water distribution pipe outlet 102.

[0041] Implementation of the present example: the waste water containing oil and organic impurities enters the tank through the water inlet pipe 101 , swirls around the water distribution pipe 103 in the tank for a circle, and flows out through the outlet 102 of the water distribution pipe. Because of the different densities of machinery, water, and oil, a three-phase separation is finally formed. The dirty oil floats up and is collected by the oil collection port, and the machinery sinks and is discharged into the sludge tank from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com