Production line and method of non-autoclaved light building blocks

An autoclave-free, production line technology, applied in the field of building materials, can solve the problems of large cost input and large production energy consumption, and achieve the effects of reducing equipment investment, small pollutant emissions, and high resistance to pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

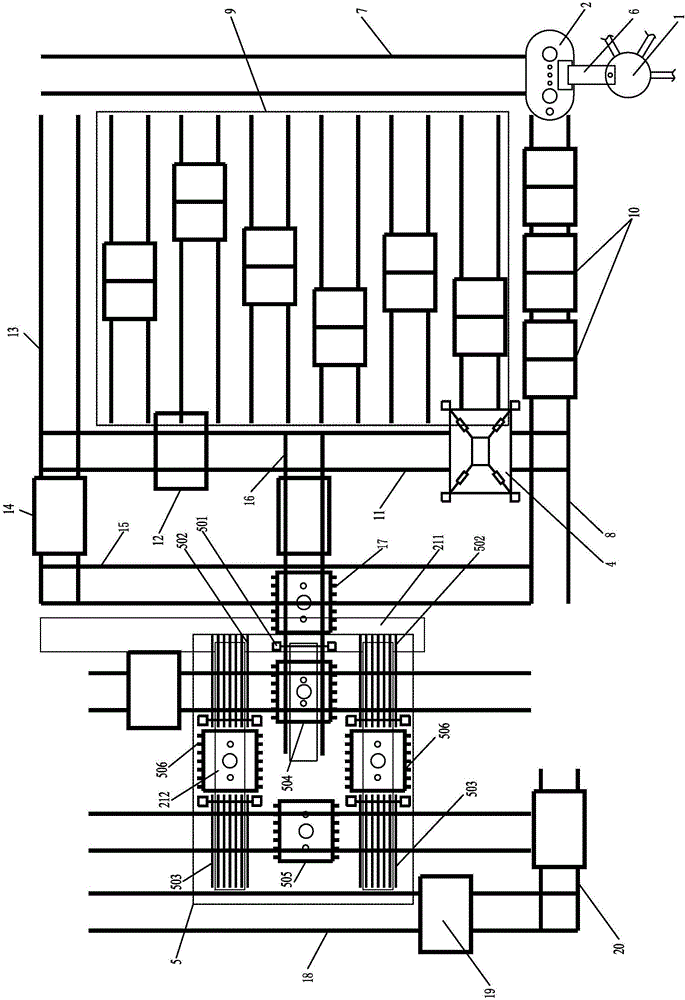

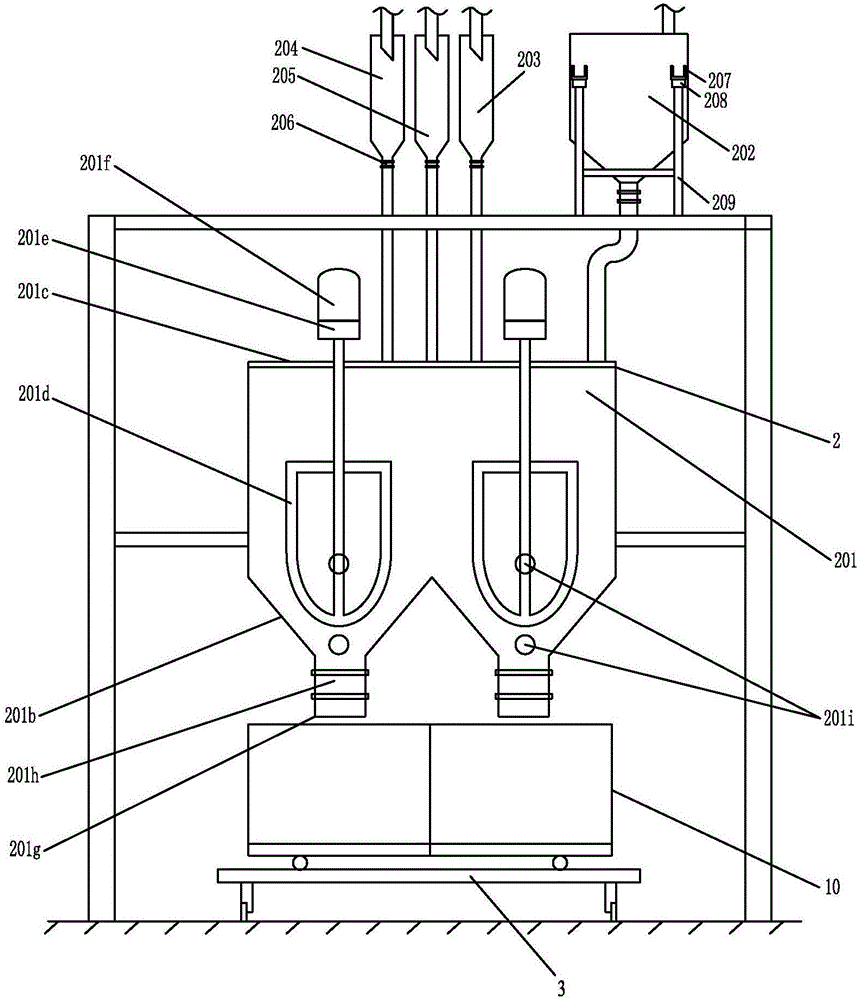

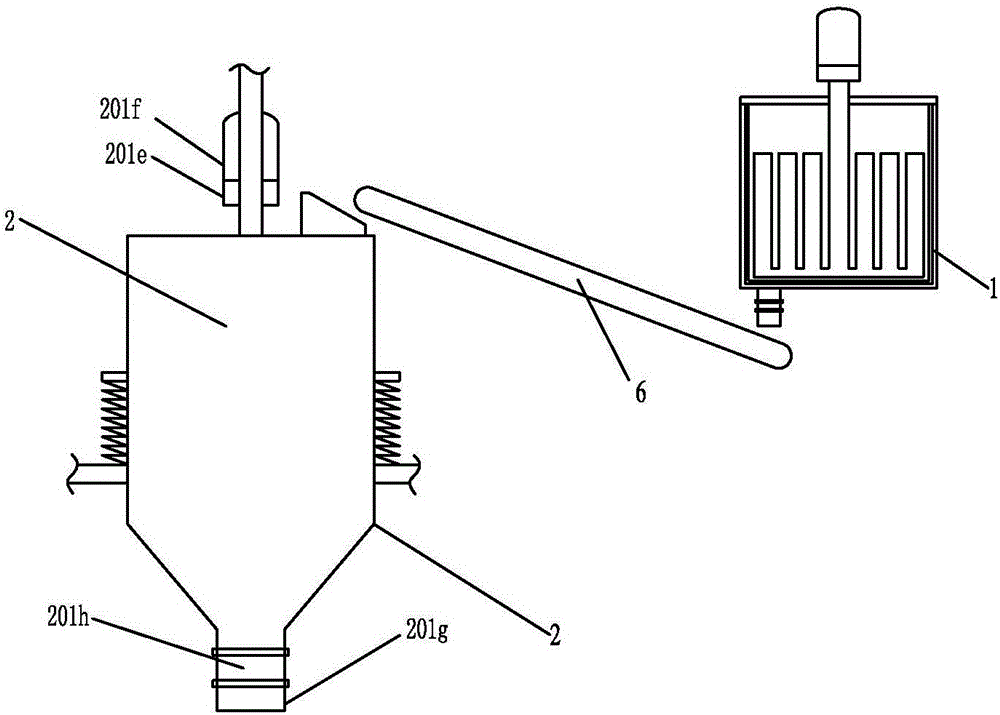

[0032] combine figure 1 , 2 and 3 to illustrate, the production line of the autoclaved lightweight block includes a dry powder mixing tank 1, a pouring system 2, a first ferry car 3, a demoulding manipulator 4, a cutting system 5, and the discharge port at the bottom of the dry powder mixing tank 1 It is arranged above the end of the dry powder conveyor belt 6, the feed port of the pouring system 2 is correspondingly arranged below the other end of the dry powder conveyor belt 6, and the first guide rail 7 is arranged under the pouring device 3, and the first ferry car is arranged on the first guide rail 7 3. Corresponding to the outlet of the pouring system 2 and perpendicular to the direction of the first guide rail 7, the second guide rail 8 is arranged. The mold box assembly 10 can be arranged on the second guide rail 8. The rear of the second guide rail 8 is connected to the second guide rail 8. Two guide rails 8 are provided with guide rail group 9 in parallel, and desc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com