Fiber reinforced composite as well as preparing method and application thereof

A composite material and fiber-reinforced technology, which is applied in the field of fiber-reinforced composite materials and carbon fiber-reinforced composite materials, can solve problems affecting the mechanical properties of composite material parts, complex and difficult operations, and dispersion of carbon nanotubes, and achieve excellent electrical conductivity and heat generation. Wide application prospects and the effect of improving electrical and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

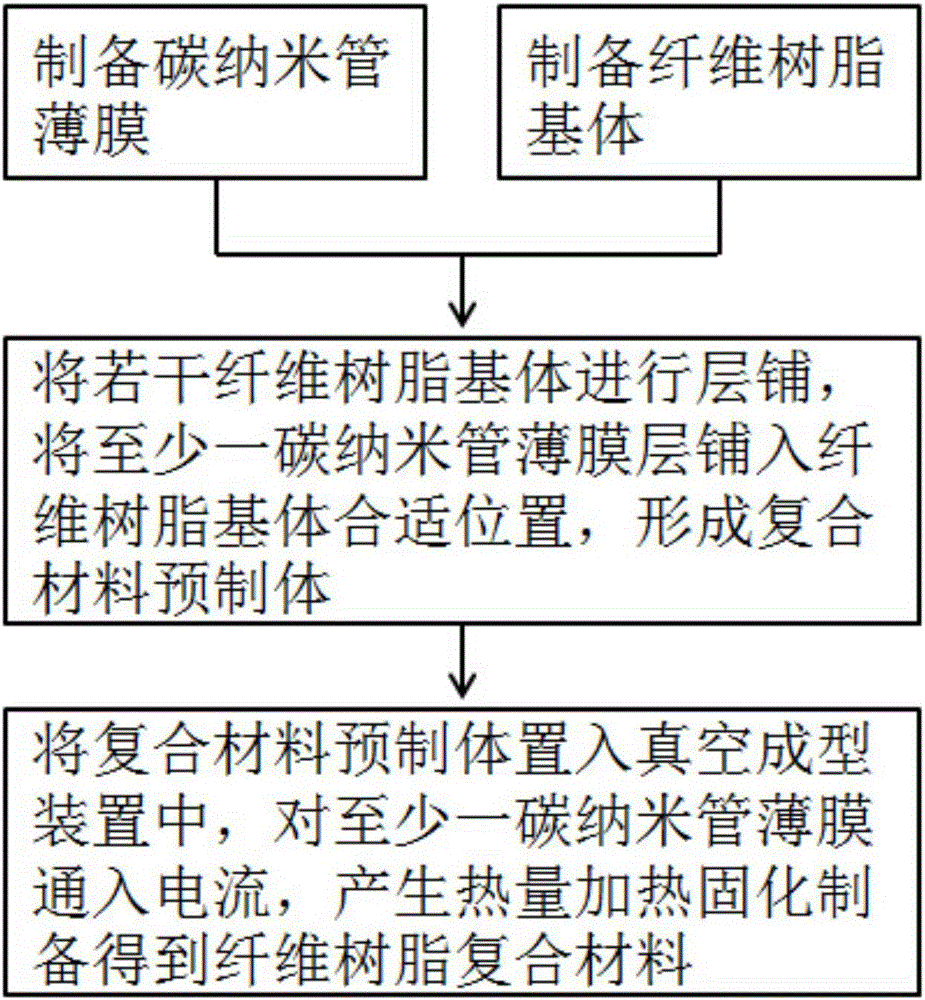

[0020] An aspect of the embodiments of the present invention provides a method for preparing a fiber-reinforced composite material, which includes:

[0021] A fiber product is provided, the fiber product comprises a fiber fabric and a resin compounded with the fiber fabric, and the resin includes a thermosetting resin and / or a thermoplastic resin;

[0022] Laminating at least one fiber product and at least one carbon nanotube film to form a composite material preform;

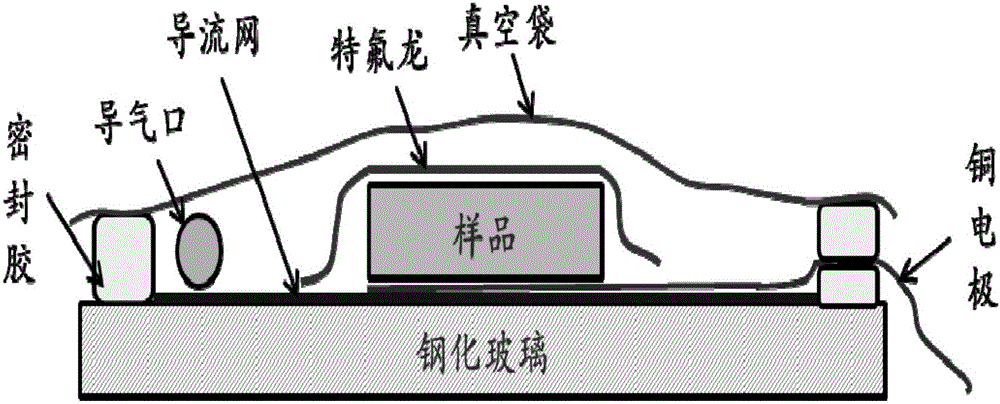

[0023] Putting the composite material preform into a vacuum forming device, then evacuating, and then passing an electric current to at least one carbon nanotube film in the composite material preform, causing the at least one carbon nanotube film to generate heat, so that the The composite material preform is heated and cured to form the fiber reinforced composite material.

[0024] Further, the carbon nanotube film includes a carbon nanotube film prepared by chemical vapor deposition or physical method. Whe...

Embodiment 1

[0061] Embodiment 1: A method for preparing a fiber-reinforced resin composite material involved in this embodiment specifically includes the following steps:

[0062] 1) Select T700, 12K carbon fiber epoxy resin unidirectional prepreg (purchased from Yixing Hengya Carbon Fiber Technology Co., Ltd., epoxy resin content is 60%) and cut it into 5cm×4cm, in which the carbon fiber is along the 5cm long side direction.

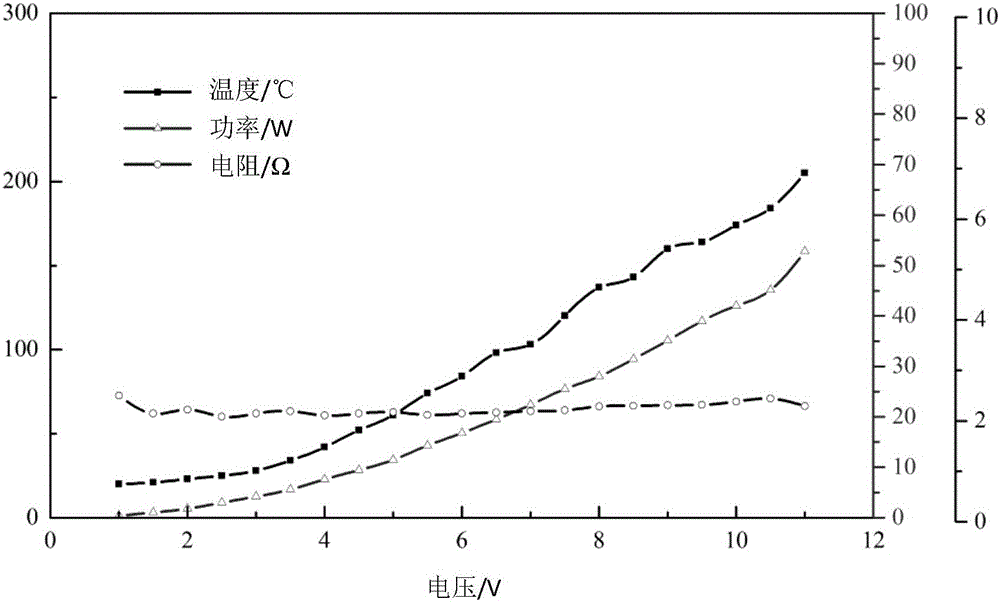

[0063] 2) Use floating catalytic chemical vapor deposition carbon nanotube film (purchased from Jiedi Nano Technology Co., Ltd., use ethanol to shrink and densify, with a thickness of 3-8 μm, and the electrothermal performance of pure carbon nanotube film can be referred to figure 2 ), cut into 5cm×4cm, wherein, the orientation direction of the carbon nanotube film is along the direction of the 5cm long side. Cut a 5mm wide copper foil as an electrode, paste and fix it on both ends of the carbon nanotube film with conductive silver glue, perpendicular to the orien...

Embodiment 2

[0066] Embodiment 2: A method for preparing a fiber-reinforced resin composite material involved in this embodiment specifically includes the following steps:

[0067] 1) Use T700, 12K unidirectional carbon fiber prepreg fabric (purchased from Yixing Hengya Carbon Fiber Technology Co., Ltd., with an epoxy resin content of 60%) and cut it into 5cm×5cm.

[0068] 2) Choose a floating catalytic chemical vapor deposition carbon nanotube film (purchased from Jiedi Nano Technology Co., Ltd., use ethanol to shrink and densify, with a thickness of 3-8 μm), and perform laser etching treatment on it. The processing method is: carbon nanotubes The tube film is spread on the stage, and the laser is adjusted to focus on the surface of the carbon nanotube film to form a point. The focused laser can etch a circular perforation on the carbon nanotube film. The laser intensity is controlled by adjusting the current. Control, the diameter of the circular holes is 150 μm, the minimum distance bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com