Aluminum profile automatic stacking system and control method thereof

A technology of automatic stacking and aluminum profiles, which is applied to the stacking of objects, conveyor control devices, conveyor objects, etc., can solve the problem that the stacking speed is easily affected by the physical strength and fatigue factors of workers, and the labor intensity of workers is high. Palletizing neatness collapse and other problems, to achieve the effect of convenient implementation, labor cost saving, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

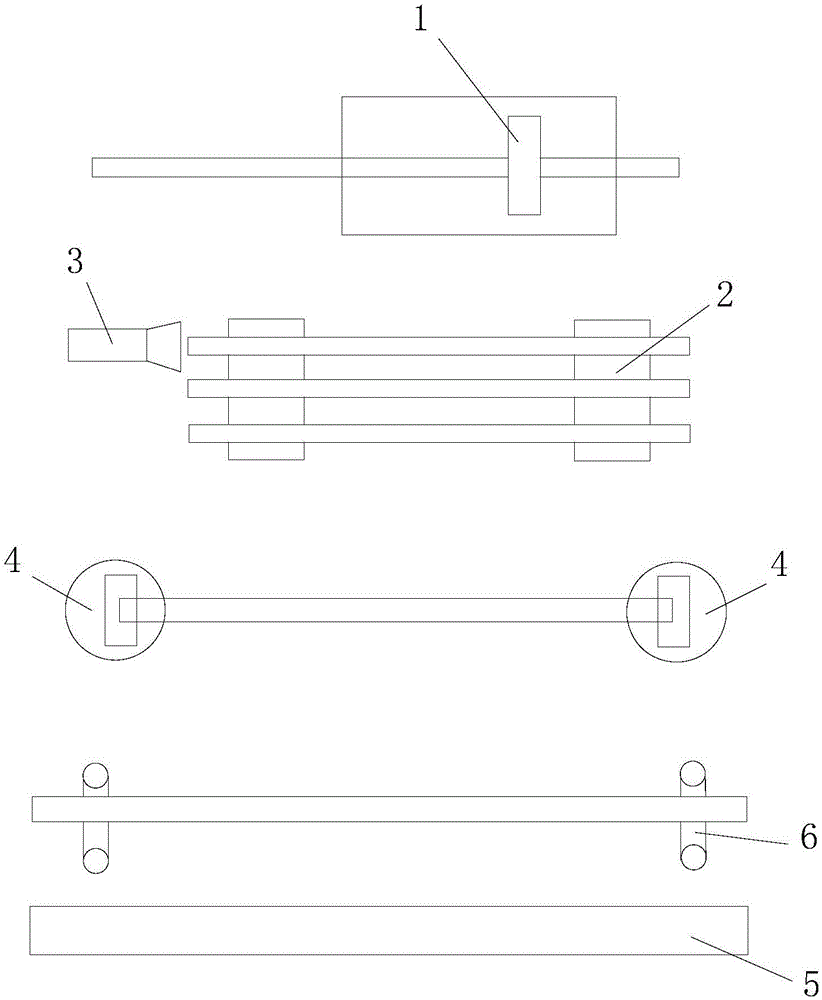

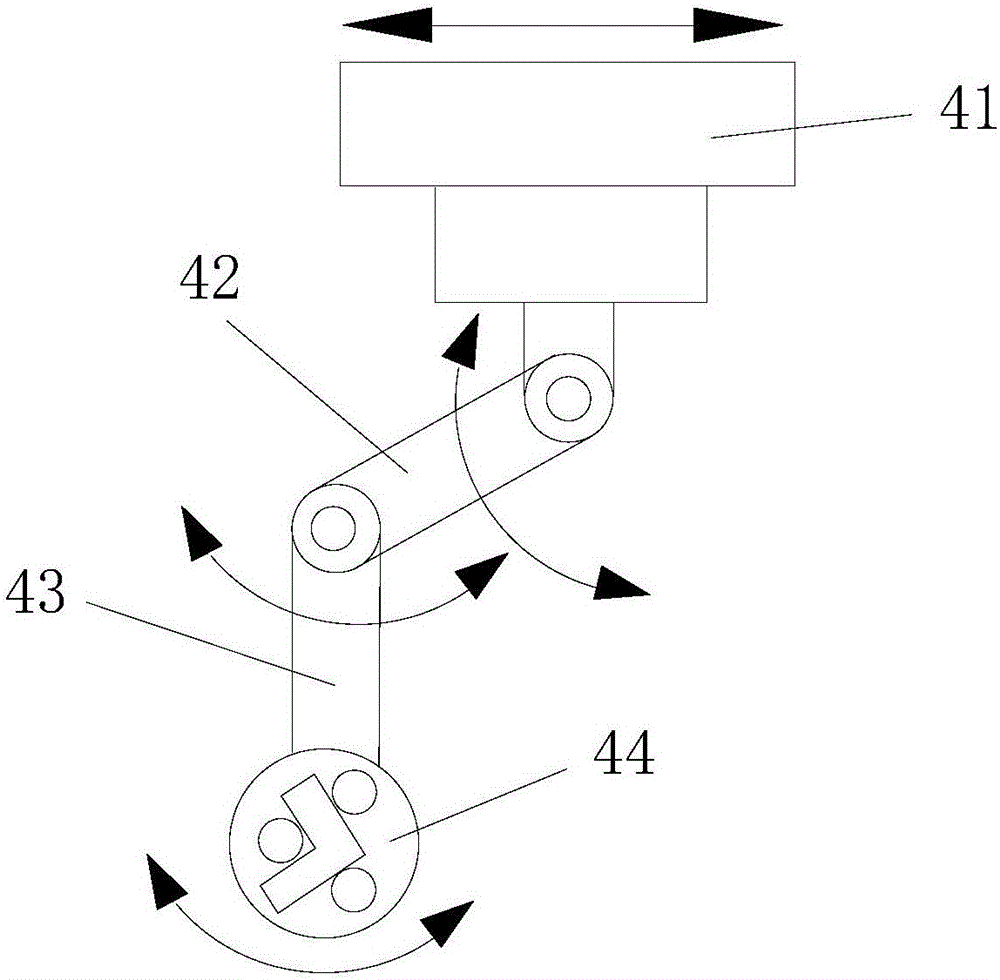

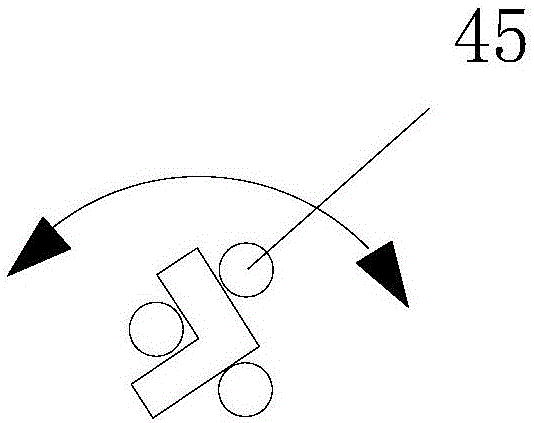

[0053] Such as figure 1 , figure 2 and image 3 As shown, the present invention discloses an automatic stacking system for aluminum profiles. The stacking system is mainly used on an aluminum profile production line to uniformly automatically identify and package aluminum profiles of various cross-sectional shapes (such as Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 Shown), reduce manual operation steps, improve automation level, thereby improving the efficiency of aluminum profile production. The stacking system mainly includes a conveyor belt 2 for transporting aluminum profiles, an industrial camera 3 for acquiring cross-sectional images of aluminum profiles, an image processor for processing image data, a first guide rail laid horizontally, a stack for grabbing workpieces Stacking manipulator 4, a gantry for transporting workpieces, and a first drive motor for driving the gantry to slide on the first guide rail.

[0054] Specifically, the industrial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com