Beta zeolite and preparation method thereof

A beta zeolite and mesoporous technology, applied in the field of beta zeolite and its preparation, can solve the problems of the inaccessibility of the active center, the influence of the catalytic activity and selectivity, the secondary reaction, etc., to accelerate the crystal growth rate and the preparation method is simple. Economical, low diffusion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

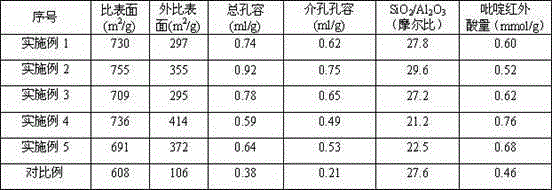

Embodiment 1

[0023] (1) Add deionized water into the stirred tank, start the stirrer and add surfactant, then add fumed silica into the stirred tank, then seal the stirred tank and raise the temperature to 150°C, and pass through Enter air to maintain the pressure in the kettle at 0.5 MPa, stir at constant temperature for 4 hours and then cool down to 50°C; add tetraethylammonium bromide, sodium aluminate and sodium hydroxide into the stirred kettle, and stir evenly;

[0024] (2) Seal the stirred tank and raise the temperature to 140°C. After stirring at constant temperature for 5 days, control the pressure at 0.38MPa by controlling the pressure relief valve, and crystallize at constant temperature for 2 days;

[0025] (3) Close the pressure relief valve, and continue the constant temperature crystallization at 140°C for 3 days. After the crystallization is completed, flush water into the kettle to quickly reduce the temperature in the kettle to below 80°C, then release the pressure, and pu...

Embodiment 2

[0027] (1) Add deionized water into the stirred tank, start the stirrer and add surfactant, then add white carbon black into the stirred tank, then seal the stirred tank and raise the temperature to 140°C, and pass through selectively Keep the pressure in the kettle at 0.7MPa with air, stir at constant temperature for 3 hours and then cool down to 50°C; add tetraethylammonium hydroxide, aluminum sulfate and sodium hydroxide into the stirred kettle, and stir evenly;

[0028] (2) Seal the stirred tank, raise the temperature to 150°C, stir at constant temperature for 2 days, control the pressure at 0.36MPa by controlling the pressure relief valve, and crystallize at constant temperature for 4 days;

[0029] (3) Close the pressure relief valve, and continue the constant temperature crystallization at 145°C for 6 days. After the crystallization is completed, flush water into the kettle to quickly reduce the temperature in the kettle to below 80°C, then release the pressure, and pump...

Embodiment 3

[0031] (1) Add deionized water into the stirred tank, start the stirrer and add surfactant, then add white carbon black into the stirred tank, then seal the stirred tank and raise the temperature to 140°C, and pass through selectively Keep the pressure in the kettle at 0.4MPa with air, stir at constant temperature for 4 hours and then cool down to 40°C; add tetraethylammonium bromide, aluminum nitrate and sodium hydroxide into the stirred kettle, and stir evenly;

[0032] (2) Seal the stirred tank and raise the temperature to 155°C. After stirring at constant temperature for 2 days, control the pressure at 0.38MPa by controlling the pressure relief valve, and crystallize at constant temperature for 3 days;

[0033] (3) Close the pressure relief valve, and continue the constant temperature crystallization at 140°C for 7 days. After the crystallization is completed, flush water into the kettle to quickly reduce the temperature in the kettle to below 80°C, then release the pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com