Preparation method and preparation device of coagulation type colloid bubbles

A colloidal and coagulation technology, which is applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, flotation water/sewage treatment, etc., can solve the problems that the treatment effect cannot be achieved, and achieve the improvement of sewage treatment effect and life Effect of long period and increase of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

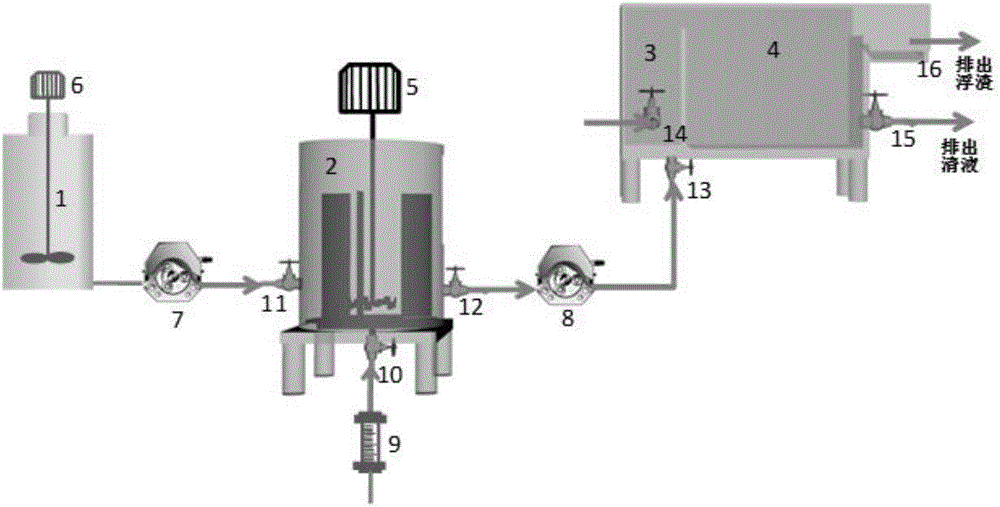

preparation example Construction

[0022] The invention provides a method for preparing colloidal colloidal bubbles, comprising the following steps:

[0023] (1) mixing the amphoteric surfactant and the coagulant to obtain a bubble generating liquid;

[0024] (2) Air is passed into the bubble generating liquid obtained in the step (1), and stirred at a stirring rate of 5000-8000 rpm to obtain coagulation-type colloidal bubbles.

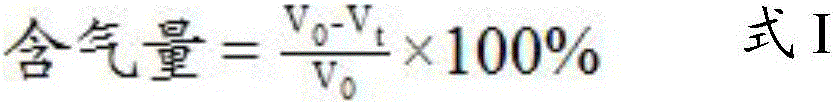

[0025] In the technical solution provided by the invention, the bubble generating liquid has a relatively high critical micelle concentration, which can reach 122-307 mg / L. The life cycle (drainage time) of the coagulation-type colloidal bubbles prepared by the method provided by the invention is long, which is 142~200s; the gas content is high, which is 53-55%; the average diameter of the coagulation-type colloidal bubbles is small, 35 to 45 μm. This can ensure that the coagulation-type colloidal bubbles maintain stable properties during the continuous process of air flotation separ...

Embodiment 1

[0040] (1) 60mg / L (as Al 2 o 3 Total) polyaluminum chloride (PACl) mixes with 109mg / L lauryl dimethyl betaine, and is stirred 5min under the condition of 40rpm at stirring rate to obtain bubble generation liquid;

[0041] (2) Pass air into the bubble generating liquid obtained in step (1), the flow rate of passing air is 33mL / min, and stir for 80s at a stirring rate of 6000rpm to obtain PACl-coagulant colloidal bubbles.

[0042] Omit the polyaluminum chloride in step (1), and prepare ordinary dodecyl dimethyl betaine colloidal bubbles according to the same method.

[0043] The product prepared after step (2) stirring in Example 1 is actually PACl-coagulation type colloidal bubble suspension and common dodecyl dimethyl betaine colloidal bubble suspension, for the PACl- Drainage dynamics test of coagulant colloidal bubble suspension and ordinary dodecyl dimethyl betaine colloidal bubble suspension: at room temperature, the newly prepared colloidal bubble suspension to be teste...

Embodiment 2

[0053] (1) 4.0mg / L (as Al 2 o 3 Total) polyaluminum chloride (PACl) mixes with 44mg / L dodecyl dimethyl betaine, and is stirred 6min under the condition of 30rpm at stirring rate, obtains bubble generation liquid;

[0054] (2) Pass air into the bubble generating liquid obtained in step (1), the flow rate of passing air is 30mL / min, and stir for 90s at a stirring rate of 5000rpm to obtain PACl-coagulation-type colloidal bubbles.

[0055] Omit the polyaluminum chloride in step (1), and prepare ordinary dodecyl dimethyl betaine colloidal bubbles according to the same method.

[0056] According to the method in Example 1, the PACl-coagulant type colloidal bubble suspension prepared in Example 2 and common dodecyl dimethyl betaine colloidal bubble suspension are carried out to discharge kinetics test, the result shows , the life cycle of common dodecyl dimethyl betaine colloidal bubbles is about 108s, and the life cycle of the PACl-coagulation type colloidal bubbles provided by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com