Dust removal and denitrification active agent for coal-fired power plants, preparation method, use method and application

A coal-fired power plant, activator technology, applied in separation methods, chemical instruments and methods, use of liquid separation agents, etc., can solve problems such as pore volume and pore size reduction, catalyst activity number reduction, catalyst poisoning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

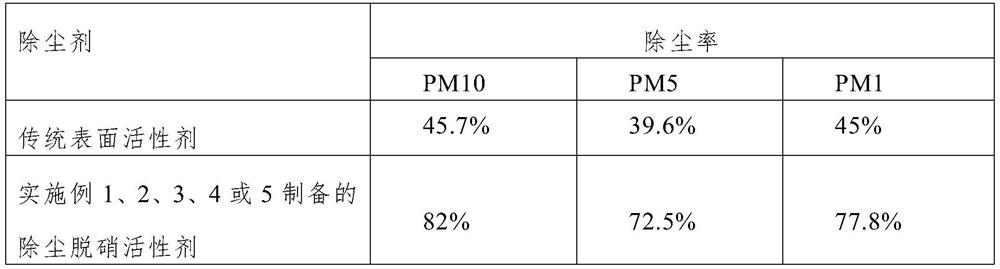

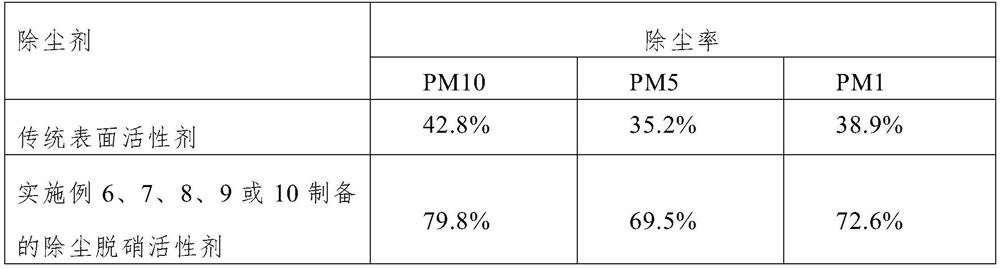

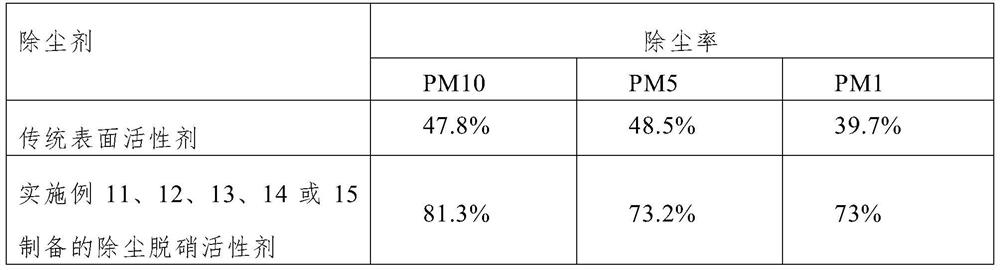

Examples

Embodiment 1

[0095] The dedusting and denitrification active agent used in coal-fired power plants in this embodiment is made from the following raw materials in mass percentage: 10% sodium dodecylbenzenesulfonate solution, 0.06% fast penetrating agent T solution, 10% sodium chloride solution, ten percent The glycol solution is 1.8%, and the balance is tap water; the mass concentration of the sodium dodecylbenzenesulfonate solution is 0.6%, and the mass concentration of the sodium chloride solution is 10%.

[0096] The preparation method of the dedusting and denitrification active agent for the coal-fired power plant of this embodiment comprises the following steps:

[0097] Step 1. Measure 100mL of sodium dodecylbenzenesulfonate solution with a mass concentration of 0.6% at a normal temperature of 25°C and pour it into a 1000mL beaker;

[0098] Step 2. Measure 0.6mL of rapid penetrant T solution, add 50mL of tap water to the measured rapid penetrant T solution to dilute, and pour the dilu...

Embodiment 2

[0103] The dedusting and denitration active agent used in coal-fired power plants in this embodiment is made from the following raw materials in mass percentage: 8% sodium dodecylbenzenesulfonate solution, 0.15% fast penetrating agent T solution, 8% sodium chloride solution, ten The glycol solution is 1.2%, and the balance is tap water; the mass concentration of the sodium dodecylbenzenesulfonate solution is 0.5%, and the mass concentration of the sodium chloride solution is 8%.

[0104] The preparation method of the dedusting and denitrification active agent for the coal-fired power plant of this embodiment comprises the following steps:

[0105]Step 1. Measure 80mL of sodium dodecylbenzenesulfonate solution with a mass concentration of 0.5% at a normal temperature of 30°C and pour it into a 1000mL beaker;

[0106] Step 2. Measure 1.5mL of rapid penetrant T solution, add 60mL of tap water to the measured rapid penetrant T solution to dilute, and pour the diluted rapid penetra...

Embodiment 3

[0111] The dedusting and denitration active agent used in coal-fired power plants in this embodiment is made from the following raw materials in mass percentage: 15% sodium dodecylbenzenesulfonate solution, 0.1% fast penetrating agent T solution, 12% sodium chloride solution, ten The glycol solution is 2.5%, and the balance is tap water; the mass concentration of the sodium dodecylbenzenesulfonate solution is 0.7%, and the mass concentration of the sodium chloride solution is 12%.

[0112] The preparation method of the dedusting and denitrification active agent for the coal-fired power plant of this embodiment comprises the following steps:

[0113] Step 1. Measure 150mL of sodium dodecylbenzenesulfonate solution with a mass concentration of 0.7% at a normal temperature of 20°C and pour it into a 1000mL beaker;

[0114] Step 2. Measure 1 mL of the rapid penetrant T solution, add 35 mL of tap water to the measured rapid penetrant T solution to dilute, pour the diluted rapid pen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com