Preparation method of high-strength greaseproof paper

A grease-proof paper, high-strength technology, applied in paper, papermaking, packaging paper, etc., can solve the problems of oil-proof paper, such as poor oil resistance, not easy to degrade, poor mechanical properties, etc., to increase the critical micelle concentration and improve the mechanical strength , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

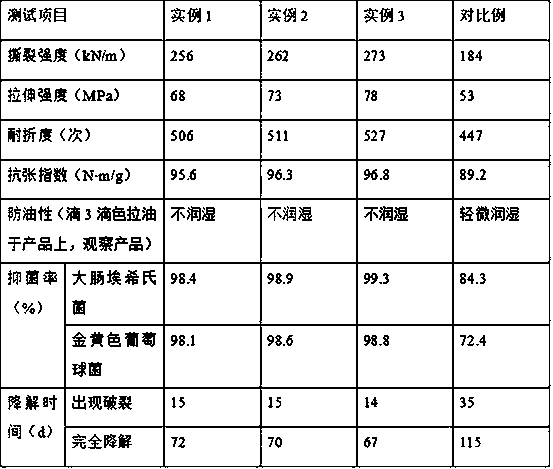

Examples

example 1

[0024] In parts by weight, weigh 4 parts of cesium fluoride, 11 parts of perfluoro-2-methyl-2-pentene, 4 parts of 4-bromobenzyl bromide and 20 parts of anhydrous acetonitrile into a sealed tube, and place Seal the tube and put it in a water bath with a water bath temperature of 80°C, and react at a constant temperature for 48 hours to obtain a reaction solution; mix the reaction solution with diethyl ether at a mass ratio of 1:2 to obtain a mixed gel solution, and use deionized water and saturated saline in sequence Wash 4 times, add anhydrous sodium sulfate to dry, filter to obtain the filtrate, put the filtrate in a vacuum drying oven, and dry it for 3 hours at a vacuum degree of 600Pa and a temperature of 50°C, and put it into column chromatography after drying. Separate and purify in the device to obtain the purified mixed solution, and set aside; weigh 500g of straw and bagasse and put them into a beaker, soak the straw with a 20% sodium hydroxide solution, put the beaker ...

example 2

[0026]In parts by weight, weigh 5 parts of cesium fluoride, 12 parts of perfluoro-2-methyl-2-pentene, 5 parts of 4-bromobenzyl bromide and 21 parts of anhydrous acetonitrile into a sealed tube, and place Seal the tube and put it into a water bath with a water bath temperature of 83°C, and react at a constant temperature for 48 hours to obtain a reaction solution; mix the reaction solution with ether at a mass ratio of 1:2 to obtain a mixed gel solution, and use deionized water and saturated saline in sequence Wash 5 times, add anhydrous sodium sulfate to dry, filter to obtain the filtrate, put the filtrate in a vacuum drying oven, and dry it for 3 hours at a vacuum degree of 700Pa and a temperature of 55°C, and put it into column chromatography after drying. Separate and purify in the device to obtain the purified mixed solution, and set aside; weigh 600g of straw and bagasse and put them into a beaker, soak the straw with a sodium hydroxide solution with a mass fraction of 23%...

example 3

[0028] In parts by weight, weigh 6 parts of cesium fluoride, 13 parts of perfluoro-2-methyl-2-pentene, 6 parts of 4-bromobenzyl bromide and 20-22 parts of anhydrous acetonitrile into a sealed tube , seal the sealed tube and put it in a water bath with a water bath temperature of 85°C, and react at a constant temperature for 48-49 hours to obtain a reaction solution; mix the reaction solution and diethyl ether at a mass ratio of 1:2 to obtain a mixed gel solution, and use deionized water in turn Wash with saturated brine for 6 times, add anhydrous sodium sulfate to dry, filter to obtain the filtrate, put the filtrate in a vacuum drying oven, and dry it for 4 hours under the conditions of a vacuum degree of 800Pa and a temperature of 60°C, and put it in the oven after drying. Separation and purification in a column chromatography device to obtain a purified mixed solution for subsequent use; Weigh 700g of straw and bagasse and put them into a beaker, soak the straw with a 25% sod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com