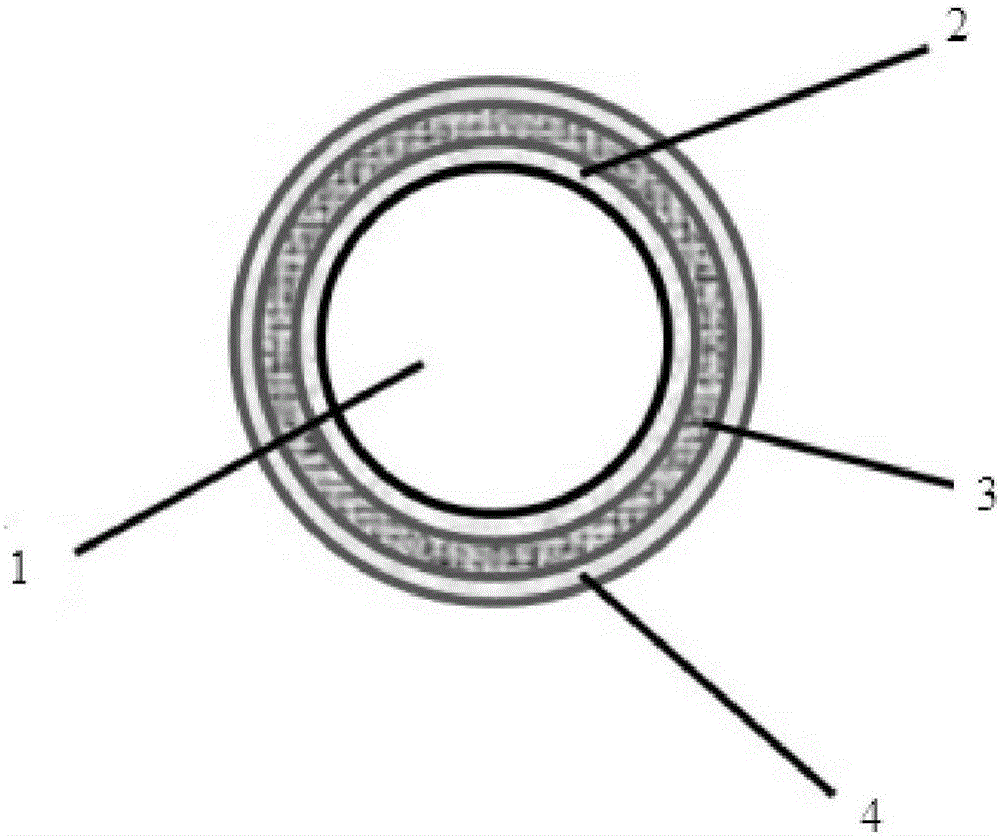

Three-layer enveloping type high-water-absorption slow release fertilizer and preparation method thereof

A technology of slow-release fertilizers and high water absorption, applied in layered/coated fertilizers, fertilizer mixtures, fertilization devices, etc., can solve the problems of high cost, high sealing requirements of production equipment, poor degradability, etc., to improve storage performance, The effect of excellent water absorption and water retention performance and good slow release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Add urea granules to the disc granulator, rotate at a constant speed, spray molten liquid paraffin at 60°C, and obtain paraffin-coated fertilizer granules after cooling. The weight ratio of paraffin to fertilizer core is 0.5:100.

[0029] (2) Put the paraffin-coated fertilizer granules obtained in step (1) into the disc granulator, spray into the atomized polyvinyl alcohol aqueous solution, the concentration is 5%, and then add the straw charcoal-based superabsorbent resin powder into the granulator. In the granulator, the straw charcoal-based superabsorbent resin powder is wrapped on the outer layer of the fertilizer granules as the middle coating layer of the slow-release fertilizer, and dried after the coating is completed. The mass ratio of straw charcoal-based superabsorbent resin to fertilizer core is 20:100.

[0030] Wherein, the method for preparing straw charcoal-based high water-absorbing slow-release fertilizer comprises the following steps:

[0031] a. ...

Embodiment 2

[0035] (1) Add urea granules to the disc granulator, rotate at a constant speed, spray molten liquid paraffin at 60°C, and obtain paraffin-coated fertilizer granules after cooling. The weight ratio of paraffin to fertilizer core is 1:100.

[0036] (2) Put the paraffin-coated fertilizer granules obtained in step (1) into the disc granulator, spray into the atomized polyvinyl alcohol aqueous solution, the concentration is 10%, and then add the straw charcoal-based superabsorbent resin powder into the granulator. In the granulator, the straw charcoal-based superabsorbent resin powder is wrapped on the outer layer of the fertilizer granules as the middle coating layer of the slow-release fertilizer, and dried after the coating is completed. The mass ratio of straw charcoal-based superabsorbent resin to fertilizer core is 20:100.

[0037] (3) Spray the coated particles of step (2) with styrene-acrylic emulsion, and finally dry to obtain coated slow-release fertilizer. The mass ratio ...

Embodiment 3

[0040] (1) Add urea granules to the disc granulator, rotate at a constant speed, spray molten liquid paraffin at 60°C, and obtain paraffin-coated fertilizer granules after cooling. The weight ratio of paraffin to fertilizer core is 2:100.

[0041] (2) Put the paraffin-coated fertilizer granules obtained in step (1) into the disc granulator, spray into the atomized polyvinyl alcohol aqueous solution, the concentration is 6%, and then add the straw charcoal-based superabsorbent resin powder into the granulator. In the granulator, the straw charcoal-based superabsorbent resin powder is wrapped on the outer layer of the fertilizer granules as the middle coating layer of the slow-release fertilizer, and dried after the coating is completed. The mass ratio of straw charcoal-based superabsorbent resin to fertilizer core is 20:100.

[0042] (3) Spray the coated particles of step (2) with styrene-acrylic emulsion, and finally dry to obtain coated slow-release fertilizer. The mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com