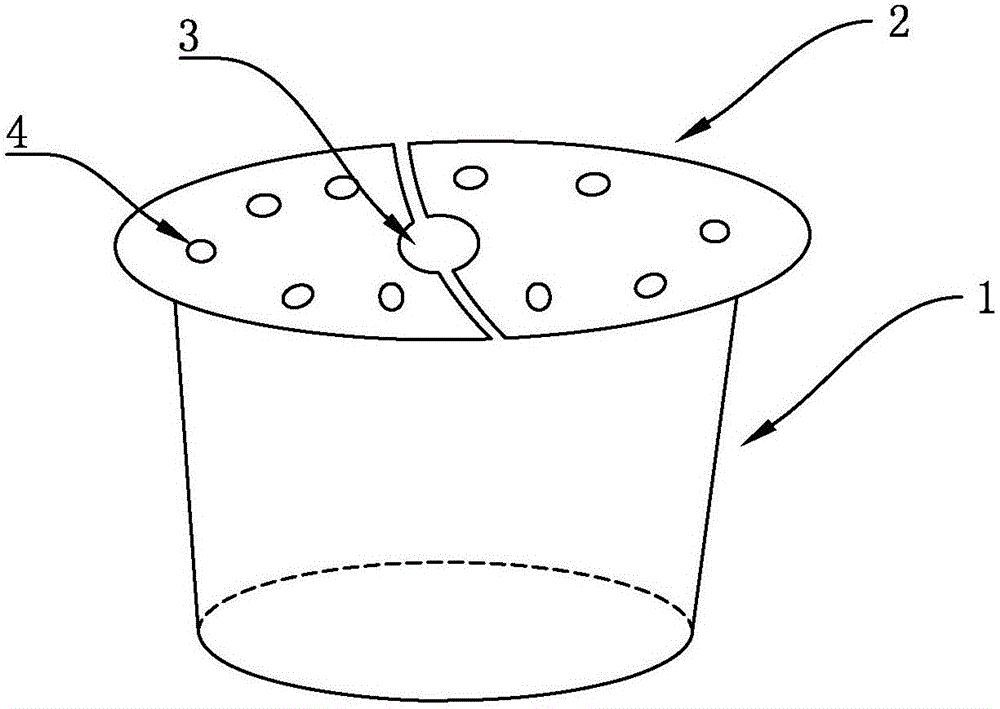

Plant cultivation bowl and preparation method thereof

A technology for cultivating pots and plants is applied in the field of plant cultivation pots and their production, which can solve the problems of large environmental changes, insufficient water resistance and insufficient water retention, and achieve the effects of shortening the planting period, obvious effects and less nutrient loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation of silage straw

[0034] Cut corn stalks, sorghum stalks, etc. into short, filled cellars, fill them up and seal them, take them out after 20 days of fermentation, and decompose the stalks initially, which is conducive to nutrient maintenance and subsequent degradation, and is also conducive to the production of subsequent processes, drying ,spare;

[0035] 2. Crush bentonite, dried cow dung, straw, soybean meal, and humic acid to 10-150 meshes, sieve, and mix with starch with a mass ratio of 10 in a mass ratio of 20:25:25:10:10;

[0036] 3. Add water to mix the raw materials in step 2, and dry until the water content is 20-25%;

[0037] 4. Pour the mixed and dried material into a hot compression molding machine for molding. Before molding, apply mold release oil (silicone oil) in the mold. The hot pressing temperature is 100°C, the hot pressing time is 150s, and the hot pressing pressure is 5Mpa;

[0038] 5. After demoulding the molded blank, coat the ...

Embodiment 2

[0043] 1. Preparation of silage straw

[0044] Cut corn stalks, sorghum stalks, etc. into short, filled cellars, fill them up and seal them, take them out after 20 days of fermentation, and decompose the stalks initially, which is conducive to nutrient maintenance and subsequent degradation, and is also conducive to the production of subsequent processes, drying ,spare;

[0045] 2. Crush bentonite, dried cow dung, straw, soybean meal, and humic acid to 10-150 mesh, sieve, and mix with starch with a mass ratio of 8 in a mass ratio of 23:25:28:8:8;

[0046] 3. Add water to mix the raw materials in step 2, and dry until the water content is 20-25%;

[0047] 4. Pour the mixed and dried material into a hot compression molding machine for molding. Before molding, apply mold release oil (silicone oil) in the mold. The hot pressing temperature is 160°C, the hot pressing time is 40s, and the hot pressing pressure is 10Mpa;

[0048]5. After demoulding the molded blank, coat the inner ...

Embodiment 3

[0053] 1. Preparation of silage straw

[0054] Cut corn stalks, sorghum stalks, etc. into short, filled cellars, fill them up and seal them, take them out after 20 days of fermentation, and decompose the stalks initially, which is conducive to nutrient maintenance and subsequent degradation, and is also conducive to the production of subsequent processes, drying ,spare;

[0055] 2. Crush bentonite, dried cow dung, straw, soybean meal, and humic acid to 10-150 meshes, sieve, and mix with starch with a mass ratio of 6 in a mass ratio of 25:30:25:7:7;

[0056] 3. Add an appropriate amount of water to evenly mix the materials in step 2, and dry until the water content is 20-25%;

[0057] 4. Pour the mixed and dried material into a hot-pressing mold machine for molding. Before molding, apply mold release oil (silicone oil) in the mold. The hot-pressing temperature is 130°C, the hot-pressing time is 100s, and the hot-pressing pressure is 15Mpa;

[0058] 5. After demoulding the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com