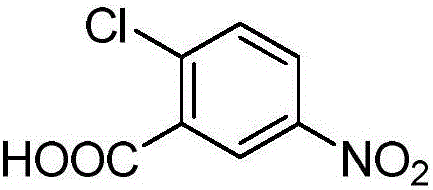

Method for synthesizing 2-chloro-5-nitrobenzoic acid through microchannel reactor

A technology of microchannel reactor and nitrobenzoic acid, which is applied in the preparation of nitro compounds and organic chemistry, etc. It can solve the problems of high risk in nitration reaction operation, excessive local concentration, large concentrated sulfuric acid, etc., so as to save equipment and land occupation The effect of space and labor cost investment, reduced consumption, and increased purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

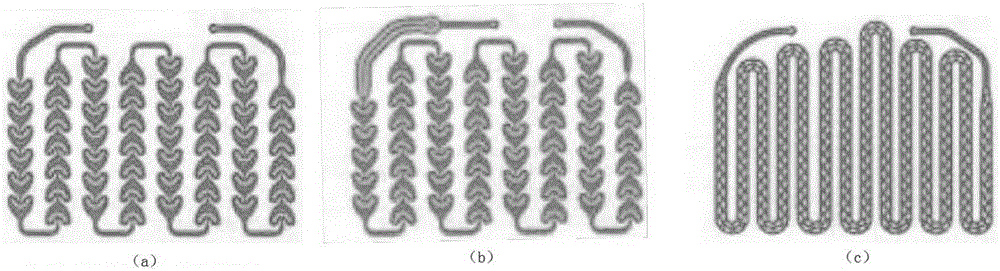

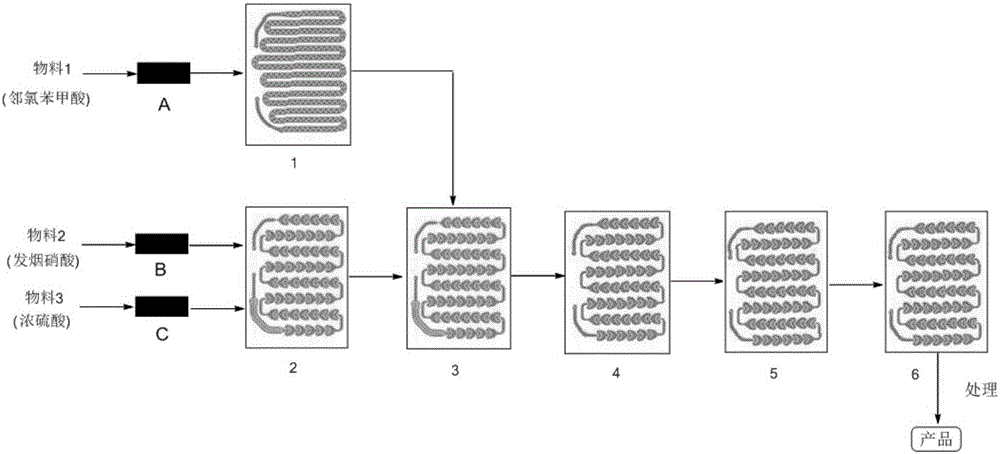

Method used

Image

Examples

Embodiment 1

[0046] (1) Take by weighing 120g of o-chlorobenzoic acid and join in 580ml of concentrated sulfuric acid and stir and dissolve as material 1, take by weighing 80g of fuming nitric acid as material 2, and take by weighing 450ml of concentrated sulfuric acid as material 3;

[0047] (2) the flow velocity of control material 1 is 15ml / min; The flow velocity of control material 2 is 3min / min; The flow velocity of control material 3 is 12min / min; Reaction temperature is 0 ℃, and the mol ratio of o-chlorobenzoic acid and nitric acid is 1 : 1.4; The residence time of reaction is 65s;

[0048] (3) After each strand of material in the reactor reaches a steady state, collect the reaction solution flowing out from the reactor outlet to feed the corresponding reaction solution of material 1 (that is, 450ml of material 1, 95.0g of o-chlorobenzoic acid) for 30min As an example, pour the collected reaction solution into 1.35L of ice-water mixture, keep stirring at room temperature for 1 hour,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com