Method for preparing paraffin dispersion liquid and paraffin microsphere from polymer microsphere produced by precipitation polymerization in situ and adopted as stabilizer

A technology of precipitation polymerization and polymer, which is applied in the field of Pickering emulsion preparation, can solve the problems of complex paraffin dispersion system, limitation of paraffin microspheres and its dispersion application, and difficulty in complete removal of additives, etc., to achieve industrial production and application , the experimental method is simple and easy, and the production cost is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

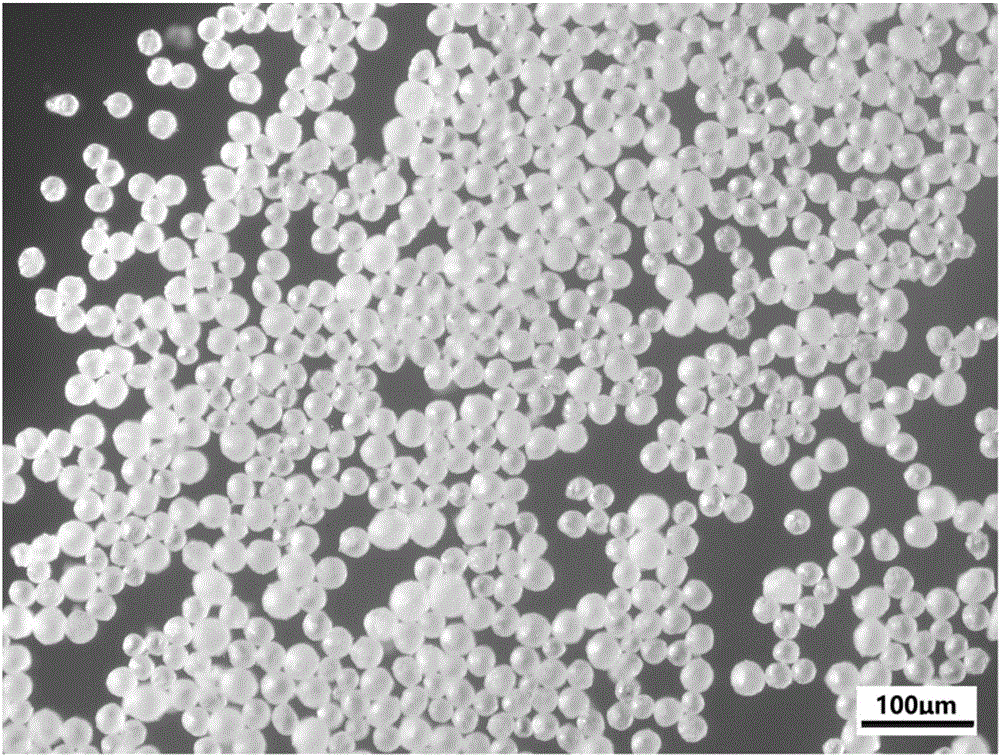

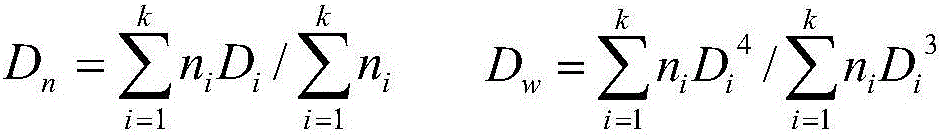

[0041] At room temperature, 80g of water / ethanol mixed solvent with a mass ratio of 10 / 90, 20g of paraffin wax with a melting point of 68°C, 0.3g of dodecene, 0.1g of trimethylolpropane triacrylate and 0.004g of azobisiso Butyronitrile was added to the reactor separately. The reactor was sealed and shaken to disperse the monomer evenly, then placed in a constant temperature water bath shaker at 75°C, and reacted for 1.0 h at a vibration frequency of 330 osc / min to obtain a paraffin wax dispersion. Keep the vibration frequency constant, add room temperature water to the constant temperature water bath oscillator to solidify the paraffin droplet. Then the system was allowed to stand at room temperature, and the upper layer liquid was removed after the layers were separated. The lower solid was dried at 60°C to obtain paraffin microspheres. The optical microscope photograph of gained paraffin microsphere sees figure 1 , the particle size of the microspheres thus measured was 2...

Embodiment 2

[0043] At room temperature, add 60g of water / ethanol mixed solvent with a mass ratio of 20 / 80, 40g of paraffin wax with a melting point of 60°C, 1.0g of tetradecene, 0.6g of pentaerythritol triacrylate and 0.03g of azobisisoheptanonitrile into the reactor. The reactor was sealed and shaken to disperse the monomer evenly, then placed in a constant temperature water bath shaker at 80°C, and reacted for 1.0 h at a vibration frequency of 150 osc / min to obtain a paraffin wax dispersion. Keep the vibration frequency constant, add room temperature water to the constant temperature water bath oscillator to solidify the paraffin droplet. Then the system was allowed to stand at room temperature, and the upper layer liquid was removed after the layers were separated. The lower solid was dried at 55°C to obtain paraffin microspheres. The particle size of the obtained paraffin microspheres was 397 μm, and the polydispersity coefficient of the particle size was 1.055.

Embodiment 3

[0045] At room temperature, 80g of water / ethanol mixed solvent with a mass ratio of 40 / 60, 20g of paraffin wax with a melting point of 45°C, 0.1g of hexadecene, 0.1g of trimethylolpropane trimethacrylate and 0.004g of peroxide Dibenzoyl was added to the reactor separately. The reactor was sealed and shaken to disperse the monomer evenly, then placed in a constant temperature water bath shaker at 70°C, and reacted for 3.0h at a vibration frequency of 200osc / min to obtain a paraffin wax dispersion. Keep the vibration frequency constant, add room temperature water to the constant temperature water bath oscillator to solidify the paraffin droplet. Then the system was allowed to stand at room temperature, and the upper layer liquid was removed after the layers were separated. The lower solid was dried at 40°C to obtain paraffin microspheres. The microsphere particle size of the obtained paraffin wax is 305 μm, and the particle size polydispersity coefficient is 1.050.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com