Rare earth-based nano-crystalline cellulose fiber film having ultraviolet ray filtering performance and preparation method thereof

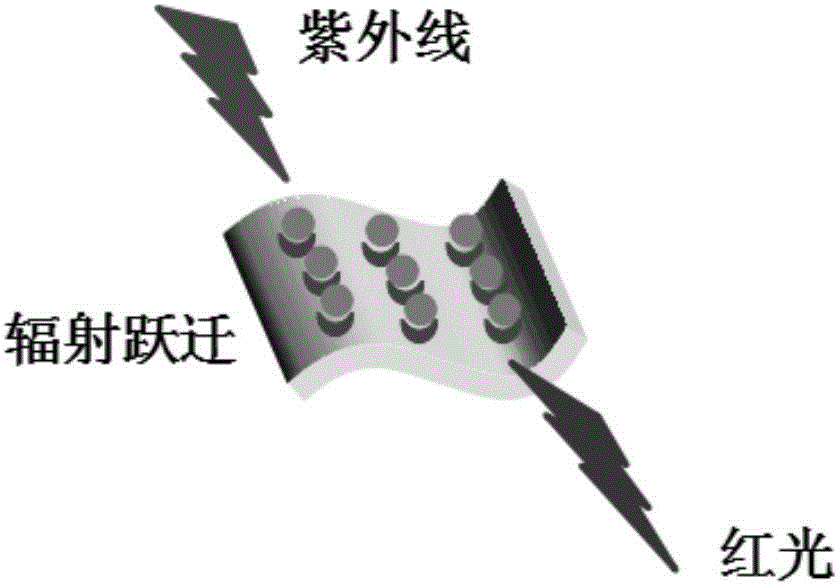

A nano-cellulose, filtration performance technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of material damage, low ultraviolet scattering efficiency, etc., to avoid agglomeration, high light transmittance, high ultraviolet light absorption rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the present invention includes the following steps:

[0035] 1. Rare earth complex Eu (TTA) 3 (H 2 O) 2 Synthesis

[0036] According to the molar ratio of 1:3, the inorganic rare earth salt EuCl 3 ·6H 2 O is mixed with 2-thenoyl trifluoroacetone (TTA), then ethanol is added in any proportion, and refluxed at 78-80°C for 3-6 hours. After cooling, filter and volatilize to obtain rare earth complex Eu(TTA) 3 (H 2 O) 2 .

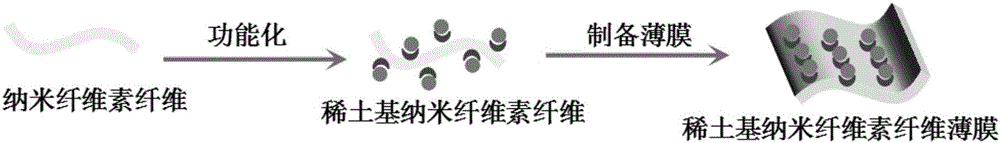

[0037] 2. Preparation of rare earth-based nanocellulose fiber Eu-NFC film

[0038] Ultrasound the nano-cellulose fibers at 400-500W ultrasonic power and 50-60KHz ultrasonic frequency for 10-15 minutes, and then mix with rare earth complex Eu(TTA) 3 (H 2 O) 2 Mix and add ethanol, reflux at 78~80℃ for 3~6h, nano cellulose fiber, Eu(TTA) 3 (H 2 O) 2 The ratio of ethanol to ethanol is (10-33) mg:1 mg: (100-150) mL; the rare earth complex is compounded on nano-cellulose fibers through solvent exchange. After cooling to room temperature, the ...

Embodiment 1

[0041] First, the massage ratio is 1:3, and the inorganic rare earth salt EuCl 3 ·6H 2 O was mixed with 2-thenoyl trifluoroacetone (TTA), then ethanol was added in any proportion, and refluxed at 78°C for 3 hours. After cooling, filter and volatilize to obtain rare earth complex Eu(TTA) 3 (H 2 O) 2 .

[0042] Then the nanocellulose fibers were sonicated for 10 minutes at an ultrasonic power of 400W and an ultrasonic frequency of 50KHz, and then combined with the rare earth complex Eu(TTA) 3 (H 2 O) 2 Mix and add ethanol, reflux for 3h at 78℃, nanocellulose fiber, Eu(TTA) 3 (H 2 O) 2 The ratio of ethanol to ethanol is 10mg:1mg:100mL; the rare earth complex is compounded on nanocellulose fibers through solvent exchange. After cooling to room temperature, vacuum filtration was performed to obtain a rare earth-based nanocellulose fiber Eu-NFC film with a thickness of 0.03 mm.

Embodiment 2

[0044] First, the massage ratio is 1:3, and the inorganic rare earth salt EuCl 3 ·6H 2 O was mixed with 2-thenoyl trifluoroacetone (TTA), then ethanol was added in any proportion, and refluxed at 79°C for 4.5 hours. After cooling, filter and volatilize to obtain rare earth complex Eu(TTA) 3 (H 2 O) 2 .

[0045] Then the nanocellulose fibers were sonicated for 12 minutes at an ultrasonic power of 450W and an ultrasonic frequency of 55KHz, and then combined with the rare earth complex Eu(TTA) 3 (H 2 O) 2 Mix and add ethanol, reflux for 4.5h at 79℃, nanocellulose fiber, Eu(TTA) 3 (H 2 O) 2 The ratio of ethanol to ethanol is 20mg:1mg:120mL; through solvent exchange, the rare earth complex is compounded on nanocellulose fibers. After cooling to room temperature, vacuum filtration was performed to obtain a rare earth-based nanocellulose fiber Eu-NFC film with a thickness of 0.06 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| UV absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com