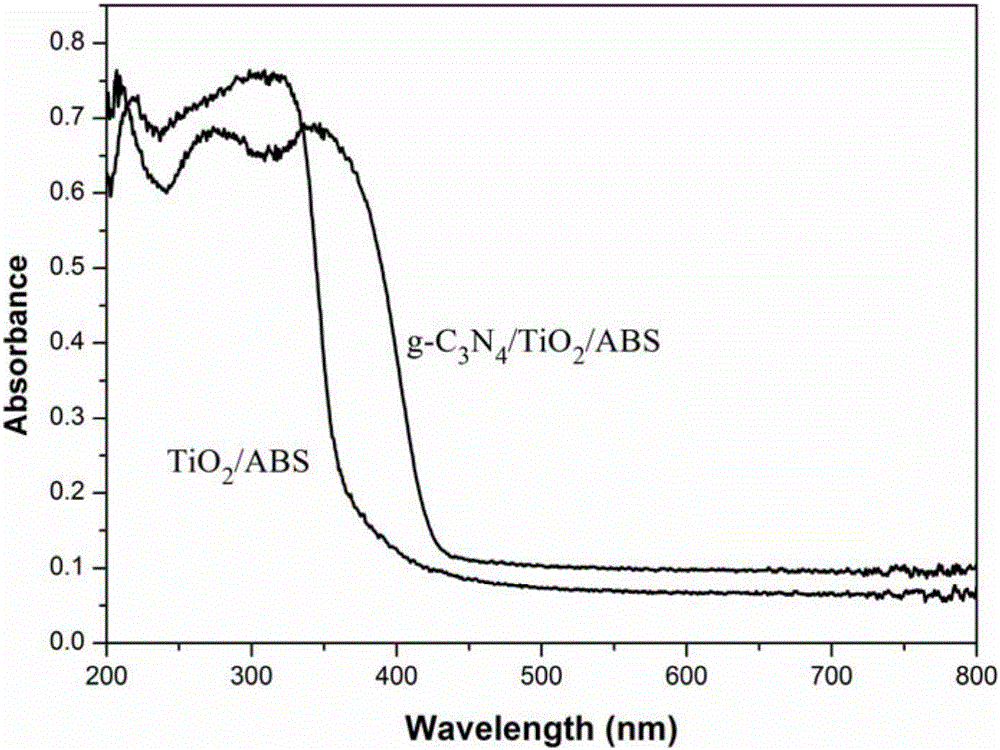

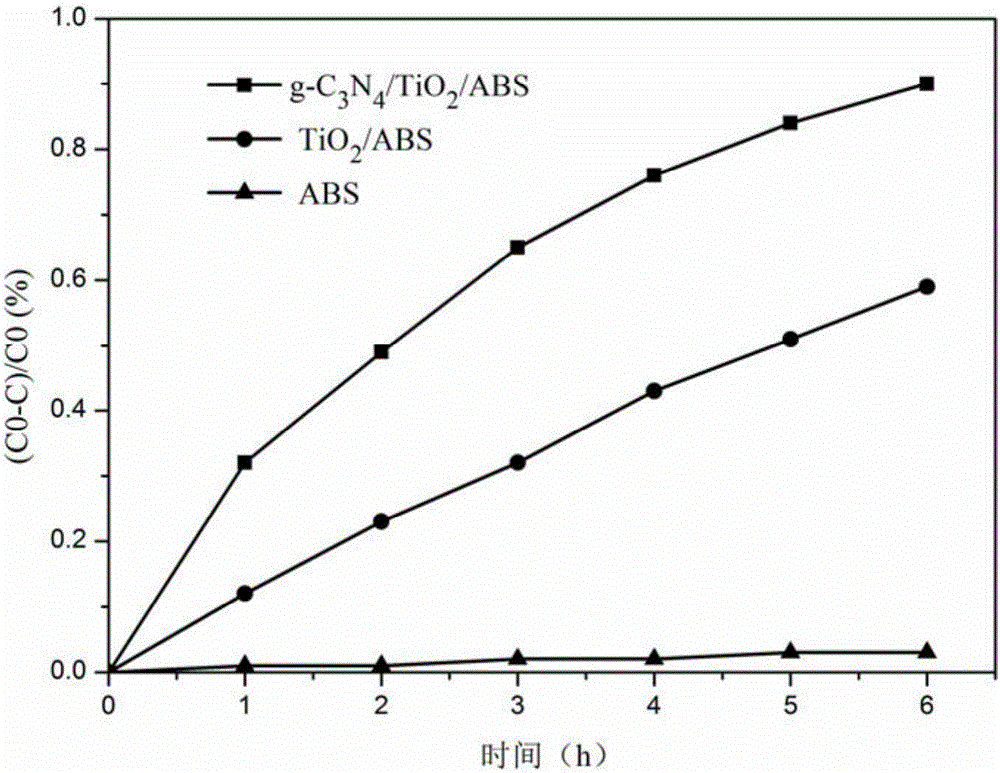

Self-cleaning acrylonitrile butadiene styrene (ABS) sheet with visible-light response and preparation method thereof

A self-cleaning, visible light technology, applied in the direction of radiation-absorbing coatings, coatings, etc., can solve the problems of low reaction efficiency, low utilization rate of visible light, low utilization rate of solar energy, etc., and achieves broad application prospects and excellent photocatalytic degradation performance. , the effect of broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a self-cleaning ABS sheet with visible light response. Put 5 g of melamine in a crucible and put it in a muffle furnace, and calcinate it at 520 °C for 6 hours at a heating rate of 10 °C / min. After natural cooling, collect the obtained Light yellow g-C 3 N 4 powder; take 0.1 g g-C 3 N 4 Disperse in 10mL of methanol, ultrasonic 1h stand-by. Take 9.6g of tetraisobutyl titanate and add it dropwise to 60mL of acetic acid (HAc), and add the sonicated g-C 3 N 4 After stirring the suspension for 0.5h, the solution was transferred to a 100mL hydrothermal kettle and reacted at 150°C for 18h. After the reaction, the product was washed several times with deionized water and ethanol, and dried in an oven at 60°C for 10 hours, and the product was collected to obtain g-C 3 N 4 / TiO 2 Powder; 27gABS (weight-average molecular weight 100000Da, butadiene rubber content 16%, number-average particle diameter 1.4μm) and 6 grams of g-C 3 N 4 / TiO 2 Add it in...

Embodiment 2

[0034] A preparation method of a self-cleaning ABS sheet with visible light response. Put 8g of cyanamide in a crucible and put it into a muffle furnace, and calcinate at 560°C for 5h at a heating rate of 15°C / min. After natural cooling, collect The resulting pale yellow g-C 3 N 4 powder; take 0.2 g g-C 3 N 4 Disperse in 15mL of methanol, ultrasonic 1h stand-by. Take 9.6g of isopropyl titanate and add it dropwise to 60mL of acetic acid (HAc), and add the sonicated g-C 3 N 4After the suspension was stirred for 0.5h, the solution was transferred to a 100mL hydrothermal kettle and reacted at 180°C for 12h. After the reaction, the product was washed several times with deionized water and ethanol, and dried in an oven at 60°C for 10 hours, and the product was collected to obtain g-C 3 N 4 / TiO 2 Powder; 42g ABS (weight average molecular weight 150000Da, butadiene rubber content 13%, number average particle diameter is 0.9μm) and 7 grams g-C 3 N 4 / TiO 2 Add to 278g of ac...

Embodiment 3

[0037] A preparation method of a self-cleaning ABS sheet with visible light response, put 5g of cyanamide and 5g of melamine mixture in a crucible, put it into a muffle furnace, and calcinate at 600°C for 4h at a heating rate of 20°C / min. After cooling, the resulting pale yellow g-C was collected 3 N 4 powder; take 0.3 g g-C 3 N 4 Disperse in 15mL of methanol, ultrasonic 1h stand-by. Take 9.6g of tetraisobutyl titanate and add it dropwise to 60mL of acetic acid (HAc), and add the sonicated g-C 3 N 4 After stirring the suspension for 0.5h, the solution was transferred to a 100mL hydrothermal kettle and reacted at 120°C for 24h. After the reaction, the product was washed several times with deionized water and ethanol, and dried in an oven at 60°C for 10 hours, and the product was collected to obtain g-C 3 N 4 / TiO 2 Powder; 24gABS (weight average molecular weight 200000Da, butadiene rubber content 10%, number average particle diameter is 3μm) and 8 grams of g-C 3 N 4 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com