Chromium-free passivant and preparation method thereof

A chromium-free passivation agent and a production method technology, applied in the direction of metal material coating process and the like, can solve problems such as lack of cost, and achieve the effects of low cost, elimination of heavy metals, and improvement of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

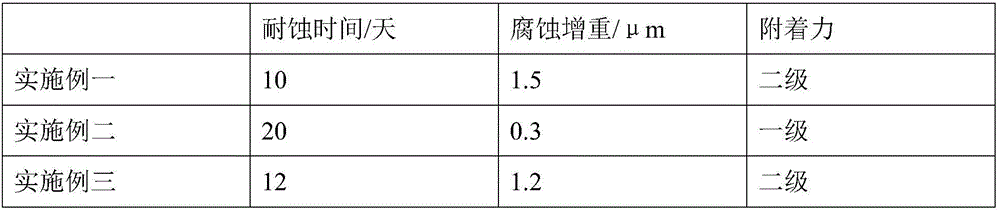

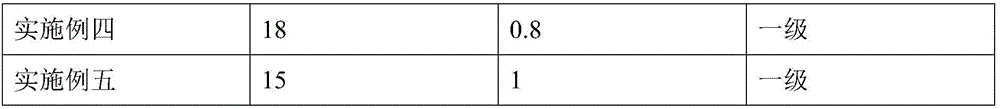

Examples

Embodiment 1

[0020] A chromium-free passivating agent, comprising 2 parts of fluozirconic acid, 10 parts of water-based resin, 1 part of phytic acid, 3 parts of silane coupling agent, and 5 parts of bone charcoal.

[0021] A preparation method of a chromium-free passivating agent, comprising the following steps:

[0022] 1) uniformly mixing fluozirconic acid, water-based resin, and phytic acid to obtain a solvent;

[0023] 2) Pour the silane coupling agent and bone char into the solvent, and stir for 60 minutes to obtain a chromium-free passivator.

Embodiment 2

[0025] A chromium-free passivator, comprising 8 parts of fluozirconic acid, 20 parts of water-based resin, 5 parts of phytic acid, 10 parts of silane coupling agent, and 10 parts of bone char.

[0026] A preparation method of a chromium-free passivating agent, comprising the following steps:

[0027] 1) uniformly mixing fluozirconic acid, water-based resin, and phytic acid to obtain a solvent;

[0028] 2) Pour the silane coupling agent and bone char into the solvent, and stir for 80 minutes to obtain a chromium-free passivator.

Embodiment 3

[0030] A chromium-free passivating agent, comprising 4 parts of fluozirconic acid, 12 parts of water-based resin, 2 parts of phytic acid, 5 parts of silane coupling agent, and 5 parts of bone charcoal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com