Method for preparing ABX3 perovskite single crystal film

A single crystal thin film, perovskite technology, applied in single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problem of not preparing perovskite single crystal thin film, and achieve high repeatability and equipment requirements. Simple, high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

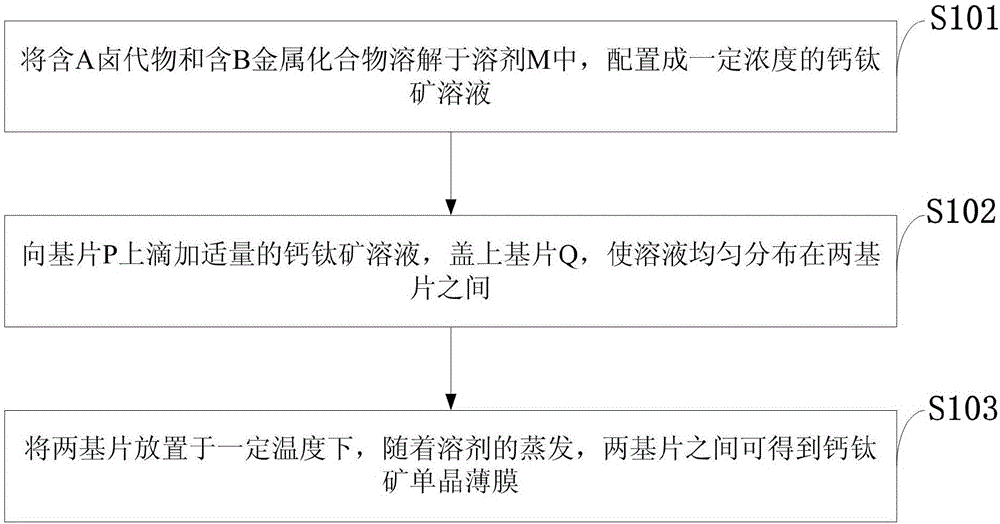

[0038] The present invention prepares ABX 3 Method for Perovskite Single Crystal Thin Films, A is CH 3 NH 3 + 、H 2 N-CH=NH 2 + , (CH 3 ) 4 N + 、C 7 h 7 + 、Cs + 、C 3 h 11 SN 3 2+ One or more of, B is one or more of Pb, Ge, Sn; X is one or more of Cl, Br, I, and the specific method includes the following steps:

[0039] 1) Weigh one or more of the above-mentioned halogenated organic and inorganic substances containing A and one or more metal compounds containing B into a 50ml beaker that has been added with a stirring bar.

[0040] Among them, the A-containing halides contain organic or inorganic ions with a radius of One or more mixtures of organic or inorganic halogenated compounds, including chloromethylamine (CH 3 NH 3 Cl), chloroformamidine (H 2 N-CH=NH 2 Cl), tetramethylammonium chloride ((CH 3 ) 4 NCl), Chlorazolium (C 7 h 7 Cl), chlorinated 2-isothiourea (C 3 h 11 SN 3 Cl 2 ), methyl bromide (CH 3 NH 3 Br), formamidine bromide (H 2 N-CH=N...

Embodiment 2

[0051] 1. Configure the solution

[0052] Weigh 0.2462g methyl bromide (CH 3 NH 3 Br), 0.8074g lead bromide (PbBr 2 ) into a 50ml beaker with a stirring bar, add 10ml N,N-dimethylformamide (DMF), put it on a magnetic stirrer and stir at room temperature for more than 2 hours to obtain a colorless, clear and transparent precursor solution. is 0.22M, and the molar ratio of bromomethylamine to lead bromide is 1:1.

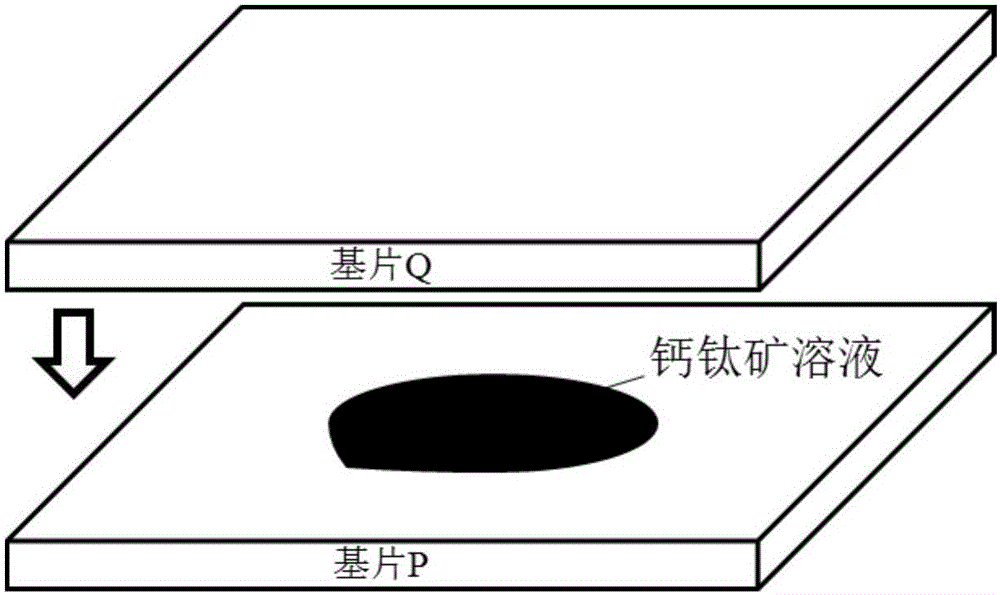

[0053] 2. Preparation of single crystal thin film

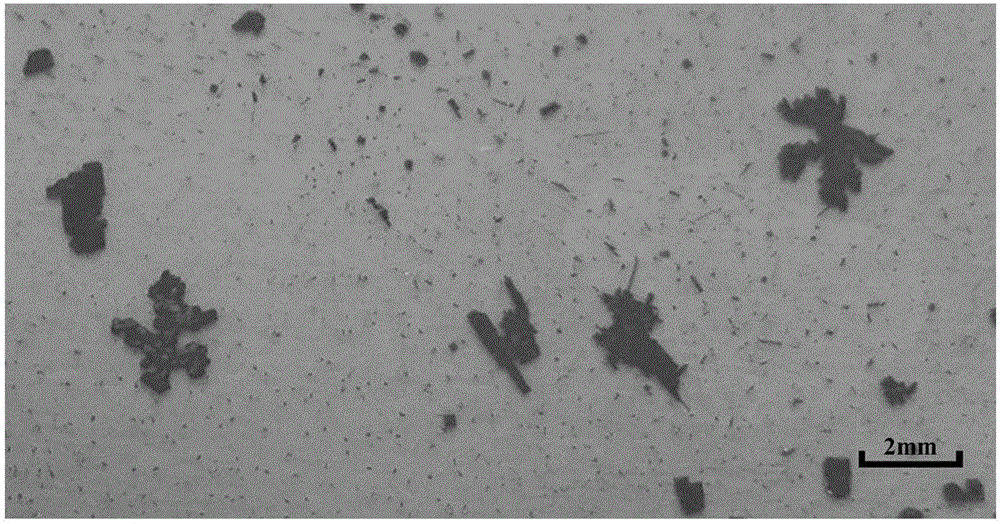

[0054] Take 100 μL of the solution in step 1, drop it in the middle of a clean 10mm×10mm glass slide, and take another glass slide to cover it, so that the solution is evenly distributed between the two glass slides, and place the two glass slides in an atmospheric environment at room temperature. After 5 days, CH can be obtained between the two glass sheets 3 NH 3 PbBr 3 single crystal film.

Embodiment 3

[0056] 1. Configure the solution

[0057] Weigh 0.7833g bromomethylamine (CH 3 NH 3 Br), 2.5690g lead bromide (PbBr 2 ) into a 50ml beaker with a stirring bar, add 10ml N,N-dimethylformamide (DMF), put it on a magnetic stirrer and stir at room temperature for more than 2 hours to obtain a colorless, clear and transparent precursor solution. is 0.7M, and the molar ratio of methyl bromide to lead bromide is 1:1.

[0058] 2. Preparation of single crystal thin film

[0059] Take 100 μL of the solution in step 1, drop it in the middle of a clean 10mm×10mm glass slide, take another glass slide to cover it, so that the solution is evenly distributed between the two glass slides, and place a 5kg glass with a flat bottom on the cover glass slide. put the above device in room temperature and atmospheric environment, after 5 days, CH can be obtained between the two glass sheets 3 NH 3 PbBr 3 single crystal film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com