Vacuum electron beam welding method and application of vacuum electron beam welding method to welding of hydroelectric steel

A technology of vacuum electron beam and welding method, which is applied in the direction of electron beam welding equipment, welding/welding/cutting items, welding equipment, etc., which can solve the problems of cleanliness, difficulty in guaranteeing vacuum degree, difficulty in welding seam cleaning, difficulty in welding seam forming, etc. problems, to achieve the effect of high welding difficulty, low production efficiency and fast welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

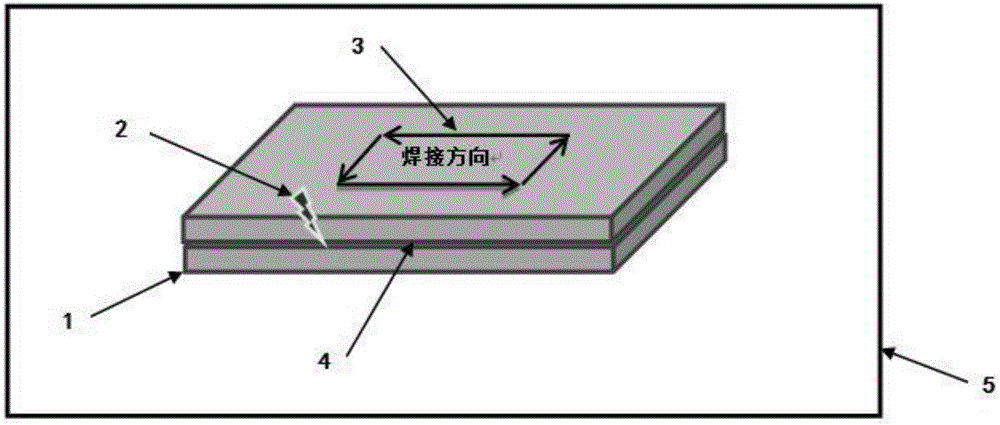

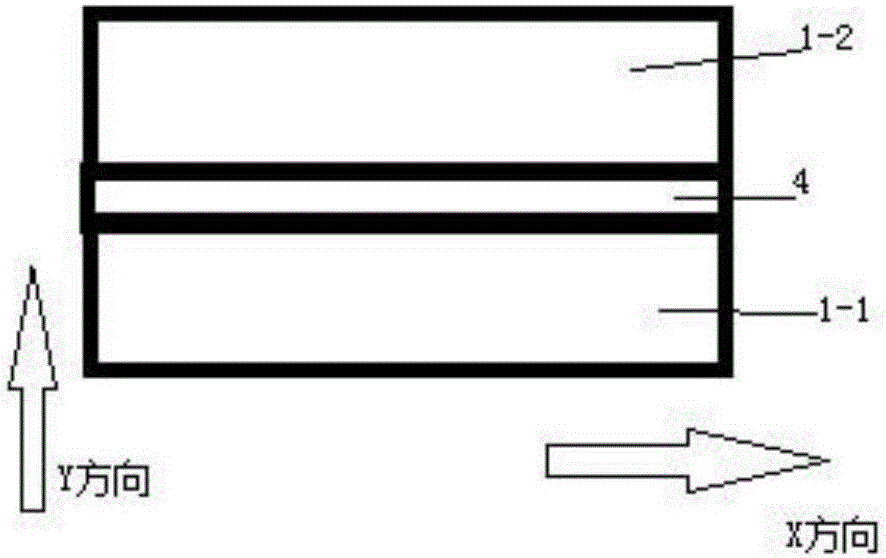

[0035] In this example, two 200mm×2200mm×4100mm (thickness×width×length) hydroelectric steel blanks were used to prepare 394±2mm×2200mm×4100mm (thickness×width×length) hydroelectric steel composite blanks by vacuum electron beam welding for use in Rolling produces extra-thick steel plates.

[0036] The chemical composition of the billet for hydroelectricity is by weight percentage: C 0.05%, Si 0.17%, Mn 1.11%, P0.0056%, S 0.0019%, Cr 0.41%, Mo 0.47%, Ni 0.14%, Cu 0.36%, V 0.026%, Nb 0.037%, Ti 0.019%, B 0.0027%, Als 0.21%, the balance is Fe and unavoidable impurities.

[0037] The vacuum electron beam welding process of the steel for hydroelectricity comprises the following steps:

[0038] (1) Surface treatment: place two blanks horizontally, and machine them with a large gantry milling machine to completely remove the iron oxide scale on the surface of the steel plate. Fresh metal is exposed on the surface of the steel plate after processing, and the surface roughness is 1.9...

Embodiment 2

[0047] In this example, two pieces of 300mm×2200mm×4000mm (thickness×width×length) hydroelectric steel blanks were used to prepare 593±3mm×2200mm×4000mm (thickness×width×length) hydroelectric steel composite blanks by vacuum electron beam welding for use in Rolling produces extra-thick steel plates.

[0048] The chemical composition of the steel billet for hydropower is by weight percentage: C 0.041%, Si 0.16%, Mn 1.01%, P0.0051%, S 0.0017%, Cr 0.37%, Mo 0.41%, Ni 0.12%, Cu 0.31%, V 0.024%, Nb 0.034%, Ti 0.017%, B 0.0021%, Als 0.19%, the balance is Fe and unavoidable impurities.

[0049] The vacuum electron beam welding process of the steel for hydroelectricity comprises the following steps:

[0050] (1) Surface treatment: Place two blanks horizontally and machine them with a large gantry milling machine to completely remove the iron oxide scale on the surface of the steel plate. Fresh metal is exposed on the surface of the processed steel plate with a surface roughness of 2....

Embodiment 3

[0059] In this example, two pieces of 400mm×1860mm×2600mm (thickness×width×length) hydroelectric steel blanks were used to prepare 791±3mm×1860mm×2600mm (thickness×width×length) hydroelectric steel composite blanks by vacuum electron beam welding for use in Rolling produces extra-thick steel plates.

[0060] The chemical composition of the billet for hydroelectricity is by weight percentage: C 0.031%, Si 0.14%, Mn 0.97%, P0.0043%, S 0.0016%, Cr 0.31%, Mo 0.37%, Ni 0.11%, Cu 0.29%, V 0.021%, Nb 0.031%, Ti 0.016%, B 0.0019%, Als 0.18%, the balance is Fe and unavoidable impurities.

[0061] The vacuum electron beam welding process of the steel for hydroelectricity comprises the following steps:

[0062] (1) Surface treatment: Place two blanks horizontally and machine them with a large gantry milling machine to completely remove the iron oxide scale on the surface of the steel plate. Fresh metal is exposed on the surface of the processed steel plate with a surface roughness of 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com