A process for separating and purifying atractylolide i and atractylolide ii in Codonopsis pilosula with macroporous adsorption resin

A technology for separation of atractylolide and resin, which is applied in the field of natural medicinal chemistry, and can solve the problems of low extract content, low content of atractylide II, difficulty in enrichment, separation and purification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

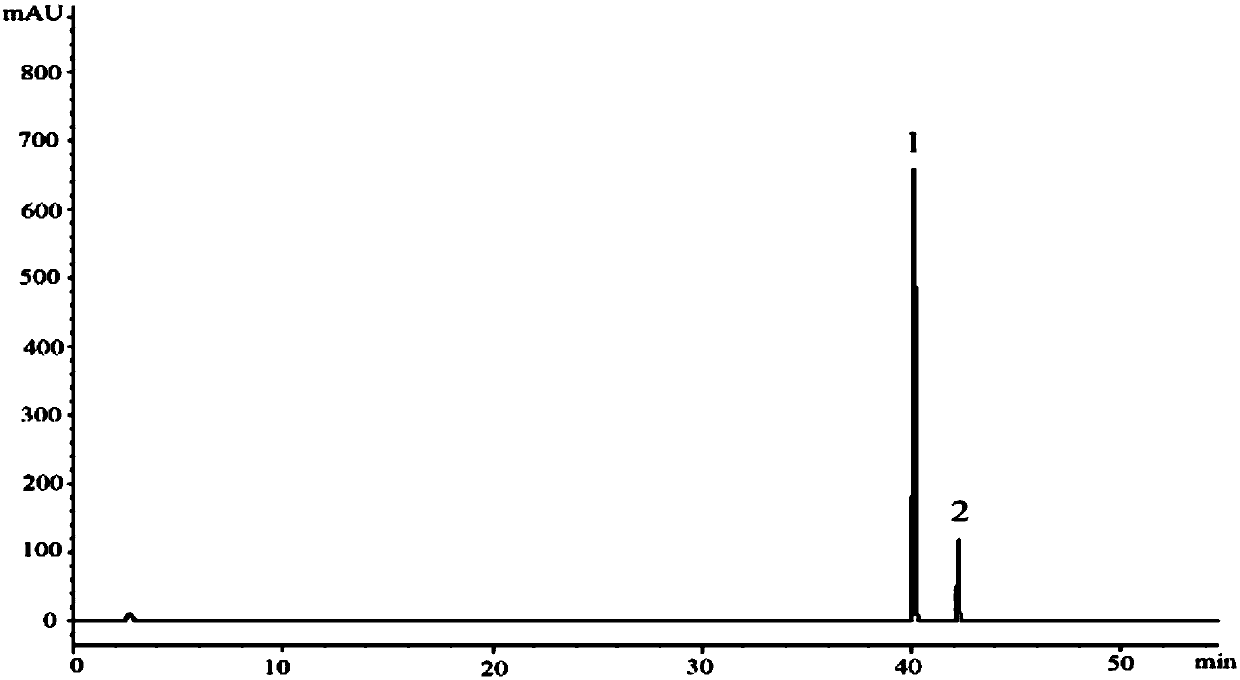

[0042] Preparation of reference solution

[0043] Accurately weigh 1.07 mg of the reference substance atractylide I and 1.12 mg of atractylide II, put them in a 10 mL volumetric flask, dissolve them with methanol and dilute to the mark, and shake well to obtain the reference substance 1. Draw up 1mL of reference substance 1 respectively, put it in a 100mL volumetric flask, dissolve it with methanol and dilute to the mark, and shake well to obtain reference substance 2.

[0044] Assay method

[0045] Chromatographic conditions: Chromatographic column: Thermo ODS HYPERSIL column; detection wavelength: 277nm for atractylolide I, 220 nm for atractylolide II; column temperature: 25°C; flow rate: 1mL / min; mobile phase: acetonitrile (B)-water (A); Gradient elution: 0 ~13min, 25%B; 13~35min, 60%B; 35~40min, 100%B; 40~55min, 100%B; injection volume: 20µL.

[0046] Optimization of Chromatographic Conditions

[0047]Selection of detection wavelength: select the absorption waveleng...

Embodiment 1

[0050] Example 1 Preparation of Codonopsis Codonopsis Crude Extract

[0051] Mix Codonopsis 95% ethanol at a weight ratio of 1:5, heat up to reflux for extraction for 2 hours, filter after completion, and concentrate the filtrate to dryness under reduced pressure. The solid is Codonopsis crude extract, which can be prepared by adding water to obtain extract solutions of different concentrations.

Embodiment 2

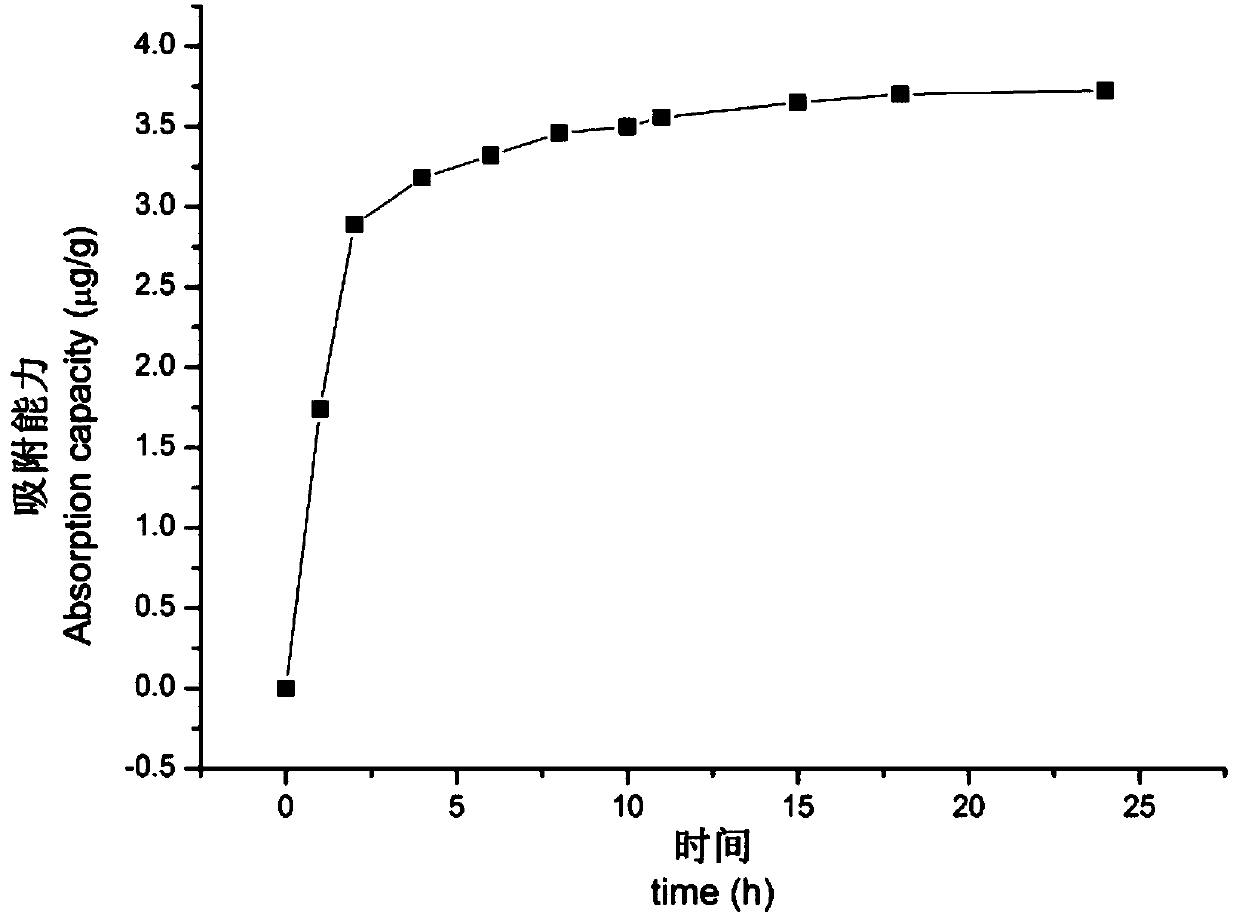

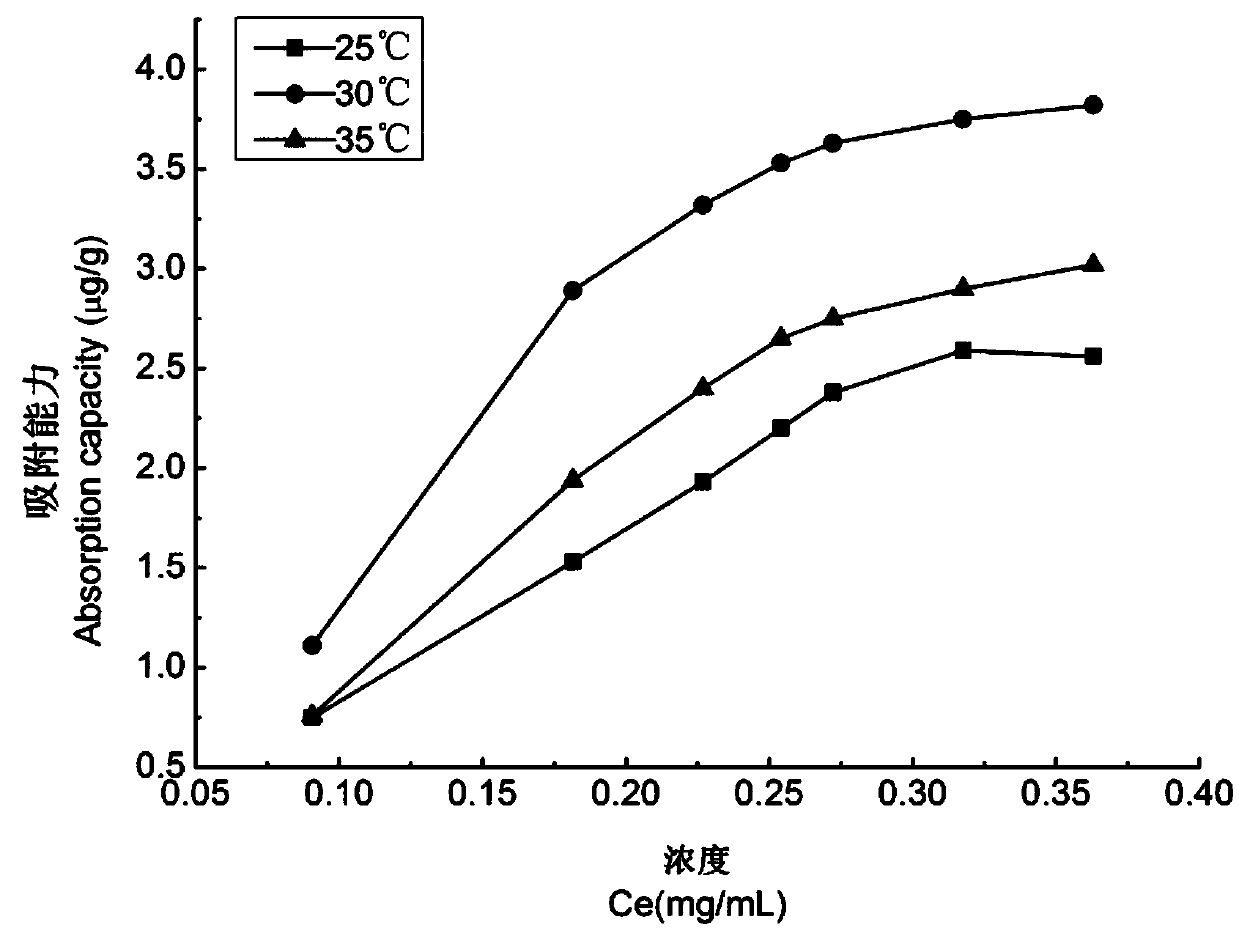

[0052] The selection of embodiment 2 macroporous adsorption resin types

[0053] The Codonopsis crude extract and water in Example 1 were prepared according to the weight / volume ratio of 0.125 g / mL to obtain an extract solution.

[0054] Weigh 1.00 g of 5 kinds of macroporous resins D101, HPD-100, H103, DM130, and S-8 that have been processed, put them into conical flasks with stoppers, add 30 mL of extract solution to each, place on a shaker and shake for 24 h, taken out, suction filtered, and the filtrate was treated for content determination. Add 50 mL of 95% ethanol solution to the resin, shake it on a shaker for 24 hours, take it out, filter it with suction, and measure the content of the filtrate as a desorption liquid after treatment. Calculate the adsorption amount, desorption amount, desorption rate and dry Solid quantity.

[0055] The calculation formulas of macroporous resin adsorption capacity, adsorption rate, desorption capacity and desorption rate are as follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com