Block koji strengthening method capable of reducing dosage of block koji and improving quality of vinegar

A high-quality and high-quality technology, which is applied in the field of biological materials and its application, can solve the problems of low saccharification ability and alcoholization ability, low vinegar production rate, etc., and achieve the effects of simple operation, increased efficiency, and broad application and promotion prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: a kind of Daqu strengthening method that reduces the dosage of Daqu and improves the quality of vinegar comprises the steps:

[0019] (1) Isolation of strains: Isolate and screen fungal strains with high production of cellulase and amylase from Daqu specially used for Shanxi mature vinegar. The specific isolation method is: collect 10g of fermented grains fermented by traditional Shanxi mature vinegar process for 24 hours in Sheng Put in a triangular flask with 90ml of sterile water, put sterile glass beads and shake for 20min to prepare bacterial suspension; pipette 1ml of bacterial suspension into a test tube filled with 9ml of sterile water, shake for 1-2min, Make it fully mixed, and then make the concentration of 10 -1 ~10 -7 Gradient bacterial suspension; draw and spread 100 μl of bacterial suspension of each dilution concentration on the Martin medium plate, make 2 parallels for each dilution, let stand for 10 minutes, and cultivate at 30°C for 3 da...

Embodiment 2

[0026] Embodiment 2: A method for strengthening Daqu by reducing the dosage of Daqu and improving the quality of vinegar. During acetic acid fermentation, the main material selected is a mixture of corn and sorghum with a mass ratio of 3:7, and the rest of the methods are the same as the preparation method described in Example 1. .

Embodiment 3

[0027] Embodiment 3: A method for strengthening Daqu by reducing the dosage of Daqu and improving the quality of vinegar. During acetic acid fermentation, the main ingredient used is sorghum, and the remaining methods are the same as the preparation method described in Example 1.

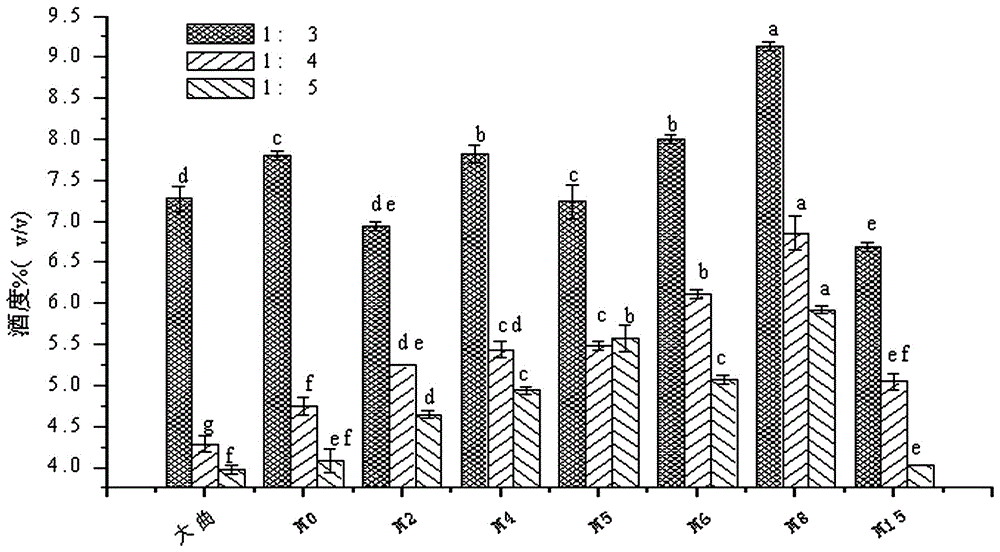

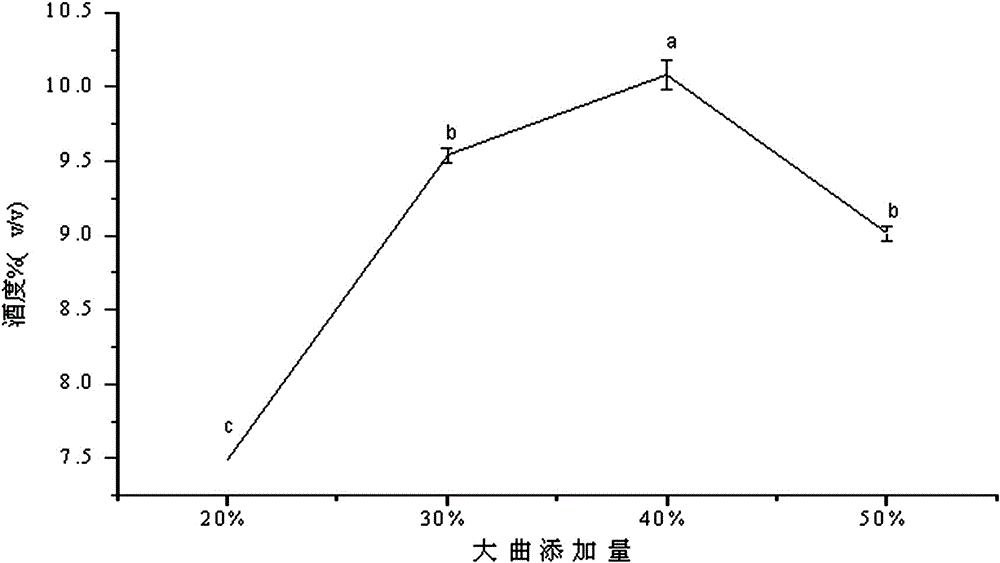

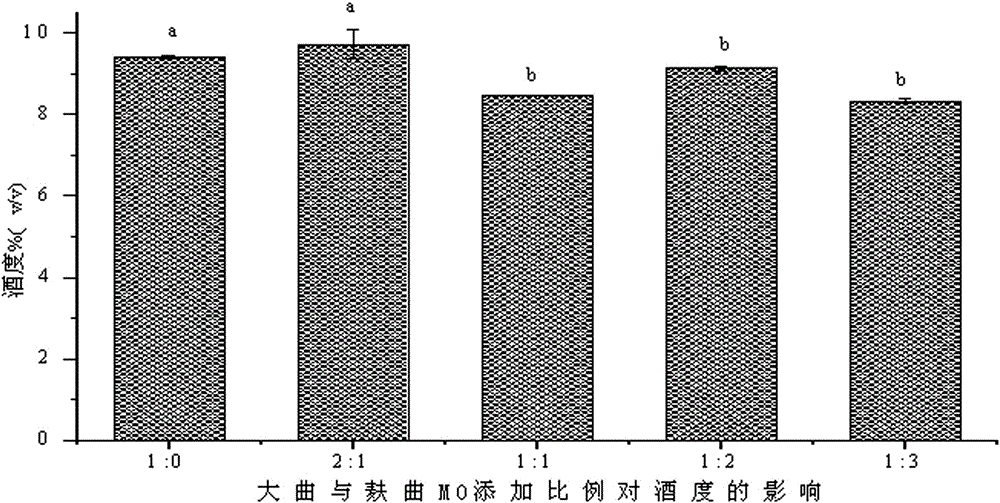

[0028] After the alcoholic fermentation, the alcohol content of mash reached 11.2% when corn was the main ingredient, 11.8% when corn and sorghum were the main ingredients with a mass ratio of 3:7, and 12.2% when sorghum was the main ingredient. Acetication and stirring provide a good alcohol content, while the alcohol content of a general vinegar factory is between 9% and 11%. The increase in alcohol content indicates that the utilization rate of raw materials has increased. After the fermentation, the starch content of vinegar grains is still very high. Therefore, the increase in the utilization rate of raw materials in the alcoholization process will not cause the problem of insufficient starch in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com