A kind of superconductor-insulator-metal heterogeneous two-dimensional crystalline thin film material and preparation method thereof

A technology of thin film materials and insulators, which is applied in the field of superconductor-insulator-metal heterogeneous two-dimensional crystalline thin film materials and its preparation, can solve the problems of heterogeneous structure thin films with many defects, performance degradation, and easy contamination of the interface, and achieve a wide range of applications. Application potential, quality improvement, effect of less defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

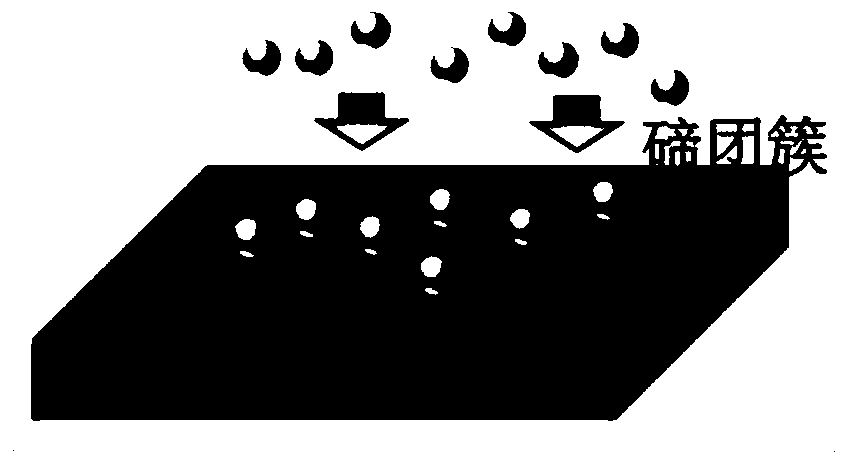

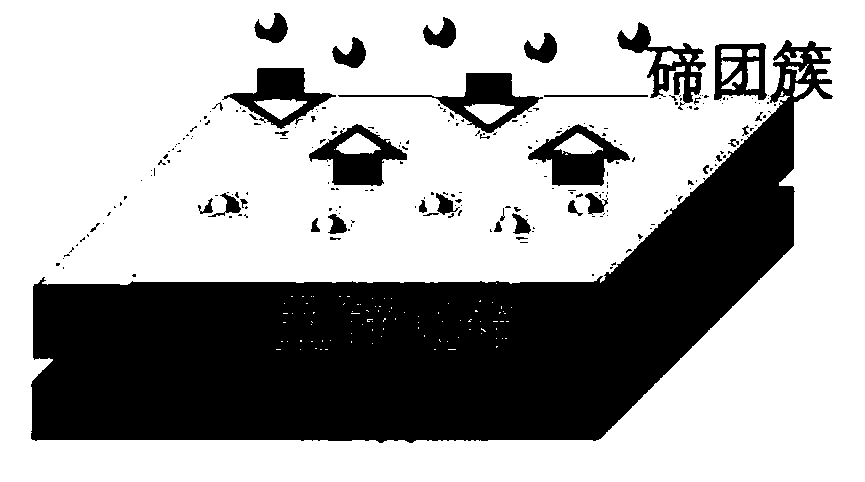

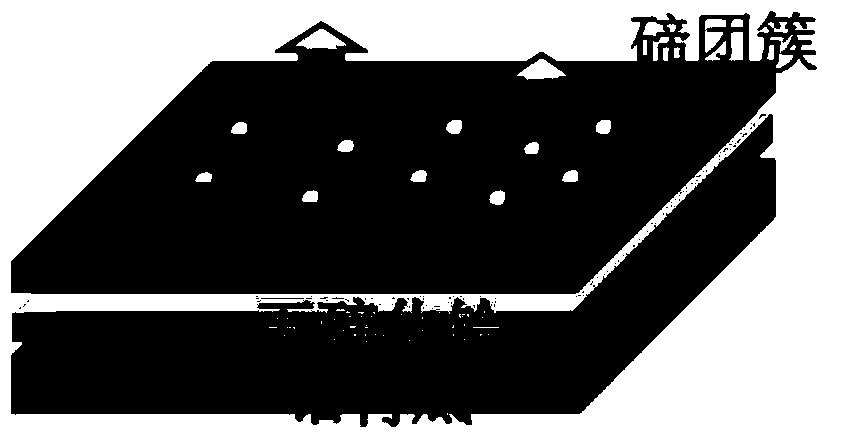

[0039]The hafnium single crystal was sputtered with argon ions for nearly 5 hours in a vacuum chamber, and then a clean and flat (0001) crystal plane was obtained by heating the metal hafnium substrate and maintaining it at a high temperature of 900 °C for 8 minutes. In a vacuum environment, an appropriate amount of high-purity tellurium was passed through a quartz crucible evaporation source, and metal tellurium was uniformly deposited on the surface of a hafnium substrate (0001) that was clean and flat and kept at room temperature. like figure 1 The tellurium particles shown are randomly distributed on the surface of the substrate, such as Figure 5 As shown in the scanning tunneling microscope image of , the samples deposited with tellurium particles were annealed at 500 °C for 15 minutes, so that the tellurium atoms covering the surface of the hafnium substrate (0001) interacted with the hafnium atoms of the substrate to form a hafnium pentatelluride film material ,like ...

Embodiment 2

[0041] The hafnium single crystal was sputtered with argon ions for nearly 3 hours in a vacuum chamber, and then a clean and flat (0001) crystal plane was obtained by heating the metal hafnium substrate and maintaining it at a high temperature of 900 °C for 5 minutes. In a vacuum environment, an appropriate amount of high-purity tellurium was passed through a quartz crucible evaporation source, and metal tellurium was uniformly deposited on the surface of a hafnium substrate (0001) that was clean and flat and kept at room temperature. The tellurium particles are randomly distributed on the surface of the substrate. The samples deposited with the tellurium particles were annealed at 450 °C for 10 minutes, so that the tellurium atoms covering the surface of the hafnium substrate (0001) interacted with the hafnium atoms of the substrate to form hafnium pentatelluride. The film material is a periodic superstructure that can be characterized by scanning tunneling microscopy, which a...

Embodiment 3

[0043] The hafnium single crystal was sputtered with argon ions for nearly 6 hours in a vacuum chamber, and then a clean and flat (0001) crystal plane was obtained by heating the metal hafnium substrate and maintaining it at a high temperature of 900 °C for 10 minutes. In a vacuum environment, an appropriate amount of high-purity tellurium was passed through a quartz crucible evaporation source, and metal tellurium was uniformly deposited on the surface of a hafnium substrate (0001) that was clean and flat and kept at room temperature. The tellurium particles are randomly distributed on the surface of the substrate. The samples deposited with the tellurium particles were annealed at 500 °C for 10 minutes, so that the tellurium atoms covering the surface of the hafnium substrate (0001) interacted with the hafnium atoms of the substrate to form hafnium pentatelluride. The film material is a periodic superstructure that can be characterized by scanning tunneling microscopy, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com