Electrochemical element separator and electrochemical element obtained using same

A technology for electrochemical components and chemical components, applied in electrical components, electrochemical generators, electrolytic capacitors, etc., can solve problems such as easy occurrence of internal short circuit, loss of isolation between positive and negative electrodes, easy generation of pinholes, etc., and achieve easy sealing , It is not easy to produce defects, and the effect of suppressing pinholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

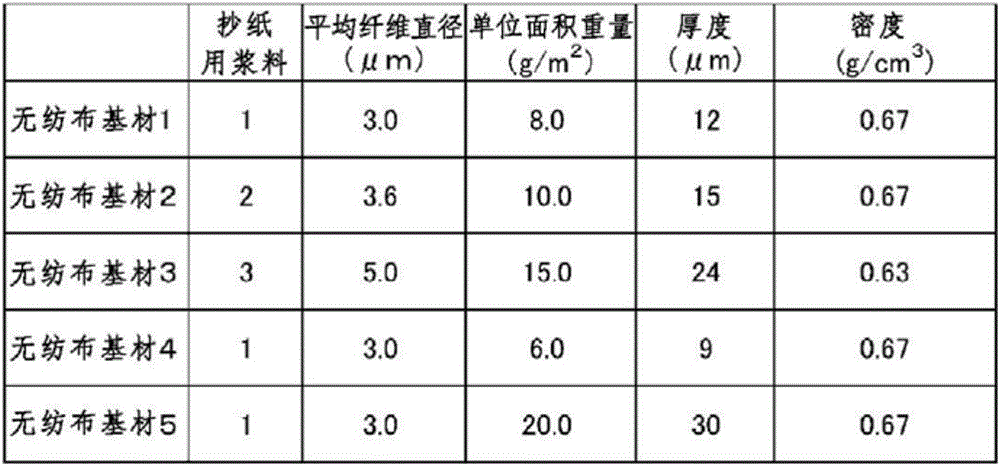

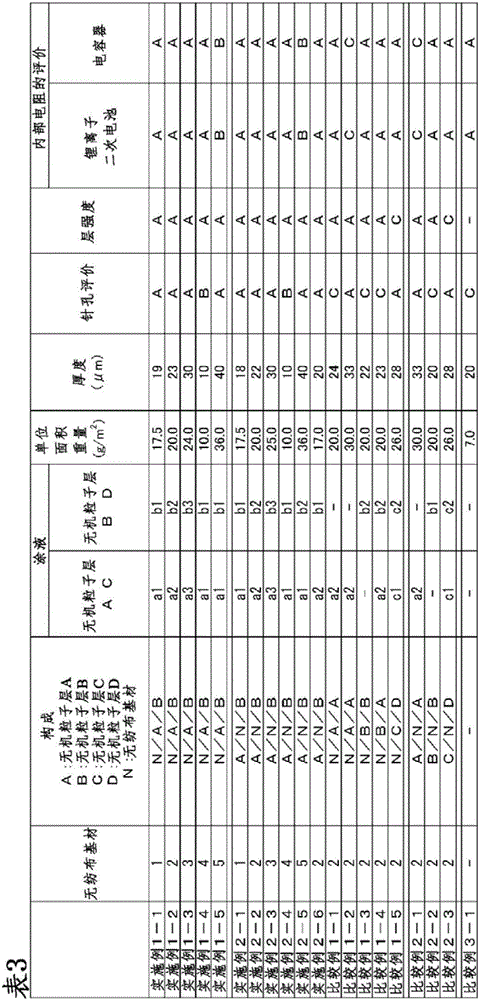

Embodiment 1-1

[0109] On the non-woven fabric substrate 1, use a reverse kiss (kiss reverse) type gravure coater to make the coating amount (dry) 7.0g / m 2 After applying the coating liquid a1 by the method and drying it, use a reverse kiss type gravure coater on the same coating surface so that the coating amount (dry) reaches 2.5g / m 2 The coating solution b1 was applied and dried in the same way as above to obtain a separator for an electrochemical element.

Embodiment 1-2

[0111] On the non-woven fabric substrate 2, use a reverse kiss type gravure coater to make the coating amount (dry) 5.0g / m 2 After applying the coating liquid a2 in the same way and drying it, use a reverse kiss type gravure coater on the same coating surface to make the coating amount (dry) 5.0g / m 2 The coating solution b2 was applied and dried in the same way as above to obtain a separator for an electrochemical element.

Embodiment 1-3

[0113] On the non-woven fabric substrate 3, use a reverse kiss type gravure coater to make the coating amount (dry) 3.0g / m 2 After applying the coating liquid a3 by the method and drying it, use a reverse kiss type gravure coater on the same coating surface so that the coating amount (dry) reaches 6.0g / m 2 The coating liquid b3 was applied and dried in the manner described above to obtain a separator for electrochemical elements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com