Waste incineration fume treatment system

A flue gas treatment system and waste incineration technology, applied in the direction of filtration circuit, liquid separation agent, combined device, etc., can solve the unfavorable problems such as widespread promotion and long-term use of waste incineration flue gas treatment technology, poor purification effect, complex structure, etc. , to achieve the effect of ensuring the cooling and purification effect of water washing, strengthening the purification function, and scientific and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

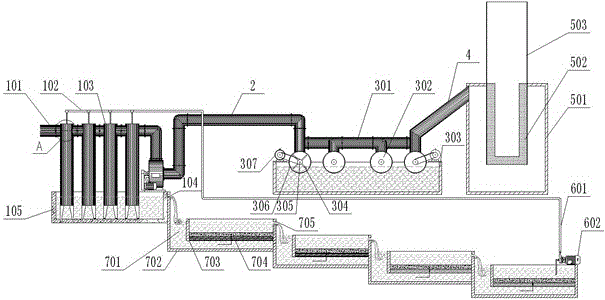

[0041] A waste incineration flue gas treatment system includes a water washing device, a liquefaction device and a filter device; the water washing device is connected to the liquefaction device through a pipeline A2; the liquefaction device is connected to the filter device through a pipeline B4.

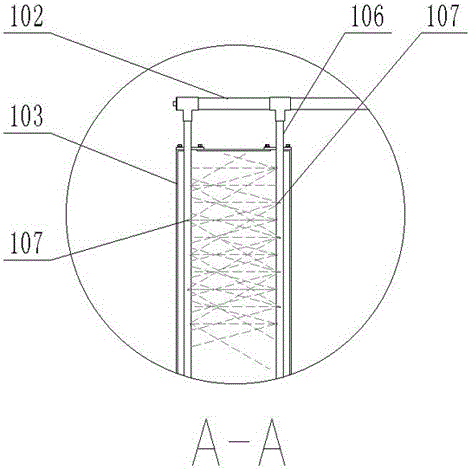

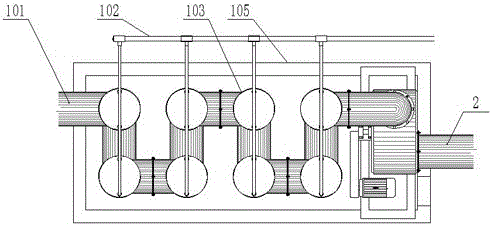

[0042] Described water washing device comprises intake main pipe 101, sedimentation tank 105, water washing tank 103 and spray parts; The top of described water washing tank 103 is connected with intake main pipe 101; 103 are installed in the sedimentation tank 105 according to the staggered front and rear positions; the spray parts include the spray main pipe 102, the spray pipe 106 and the sprayer 107; the water washing tank 103 is provided with a pair of spray Shower pipe 106, spray pipe 106 is vertically installed in the water washing tank 103; described spray pipe 106 is connected in parallel to the spray main pipe 102; The showers 107 on the pair of shower pipes 106 in 103 ar...

Embodiment 2

[0049] This embodiment differs from Embodiment 1 in that:

[0050] The water washing device is provided with 6 groups of water washing tanks 103, and the water washing tanks 103 are arranged in the settling tank 105 in a V-shaped arrangement according to front and rear positions, and the liquefaction device is provided with 4 groups of water turbines. The waste incineration flue gas treatment system also includes a purification device; the purification device includes a multi-stage permeation tank 701, and the permeation tank 701 is arranged in steps; the sedimentation tank 105 is provided with a water outlet A104, and the first-stage permeation tank 701 is connected with the water outlet A104 of the sedimentation tank 105; the osmosis tank 701 includes the pool body 702, the osmosis unit and the water outlet B705; Enclosed; the partition 703 is arranged in the pool body 702; the thickness of the sand-carbon layer 704 is lower than the height of the partition 703; the bottom o...

Embodiment 3

[0052] This embodiment differs from embodiment 2 in that:

[0053] The water washing device is provided with 8 groups of water washing tanks 103, and the water washing tanks 103 are arranged in the settling tank 105 in a staggered front and rear position. The waste incineration flue gas treatment system also includes a circulation system; the circulation system includes a circulation pump 602 and a circulation pipe 601; the circulation pump 602 is installed above the last stage of permeation tank 701; the circulation pump 602 The water inlet pipe is installed above the sand carbon layer 704, and the outlet pipe of the circulation pump 602 is connected with one end of the circulation pipe 601; the other end of the circulation pipe 601 is connected with the spray main pipe 102. The sewage in the sedimentation tank 105 infiltrates through the layers in the permeation tank 701, and the sewage is purified under the action of the sand carbon layer 704, and the purified water can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com