Turbulent flow ammonia spraying grating in boiler flue gas denitration system

A technology of boiler flue gas and ammonia injection grid, which is applied in injection devices, gas treatment, injection devices, etc., can solve the problems of small diffusion range of ammonia/air mixed gas, short service life of nozzles, poor mixing uniformity, etc., and achieve Ensure long-term safe and stable operation, prolong service life and improve mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

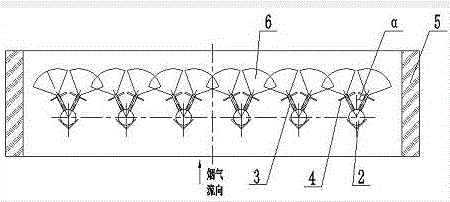

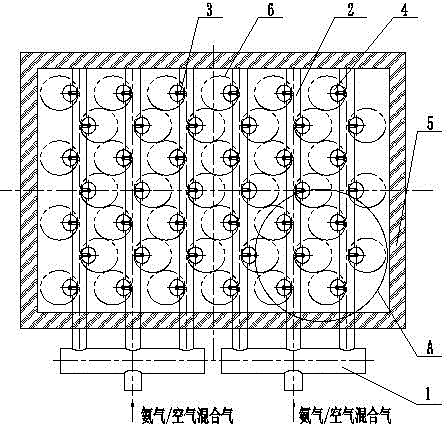

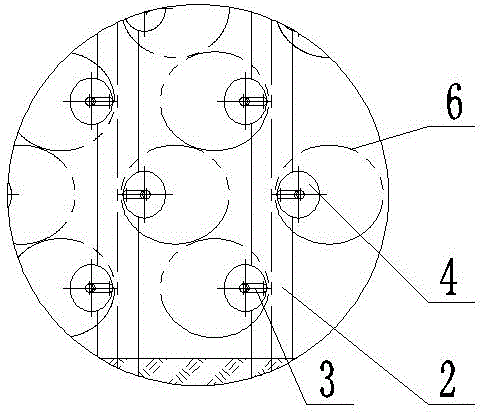

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as Figures 1 to 3 As shown, a turbulent ammonia injection grid in a boiler flue gas denitrification system includes a grid main pipe 1, a grid branch pipe 2 and a nozzle 3, and the nozzle 3 is welded to the upper half of the grid branch pipe 2, An annular spoiler 4 is welded on the nozzle 3, and the annular spoiler 4 is perpendicular to the nozzle 3 and is located at the upper end of the nozzle 3, wherein the grille main pipe 1, the grille branch pipe 2 and the nozzle 3 The quantity can be set according to the actual flue size and flue gas volume. Here, two grille main pipes 1 and six grille branch pipes 2 are designed, and each grille branch pipe 2 is equipped with 7 nozzles 3, each The nozzles 3 on the grid branch pipe 2 are arranged staggered left and right, the angle α between the nozzles 3 and the flow direction of the flue gas is 10°-45°, and the an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com