Separation system for garbage resourceful treatment

A separation system and resource-based technology, which is applied in separation methods, liquid separation, semi-permeable membrane separation, etc., can solve the problems of low separation flux, low separation efficiency, and low flow rate, so as to save steam consumption and improve heating efficiency , to avoid the effect of burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

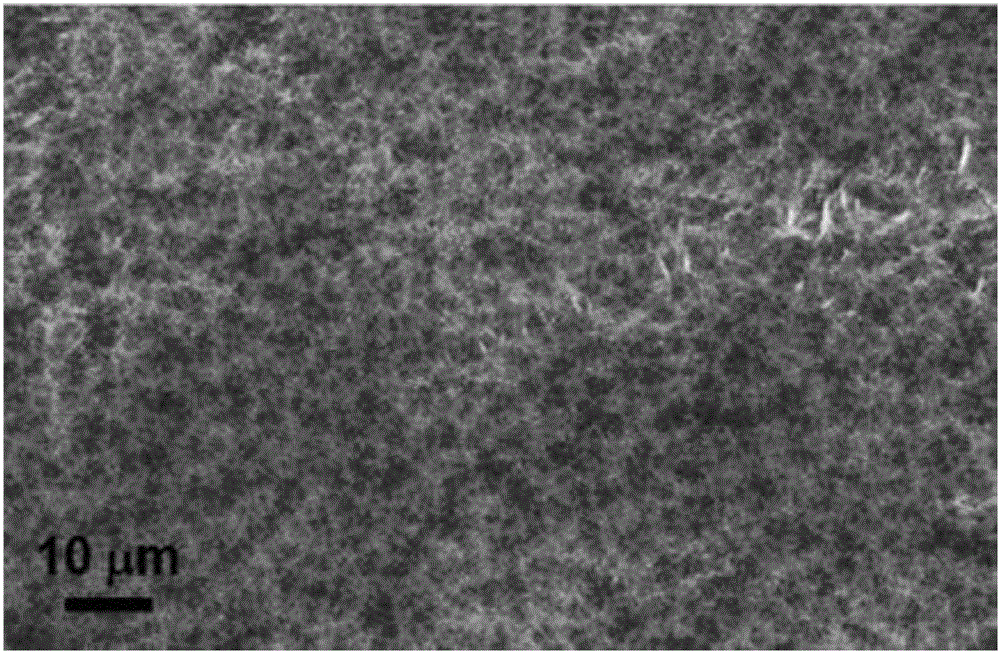

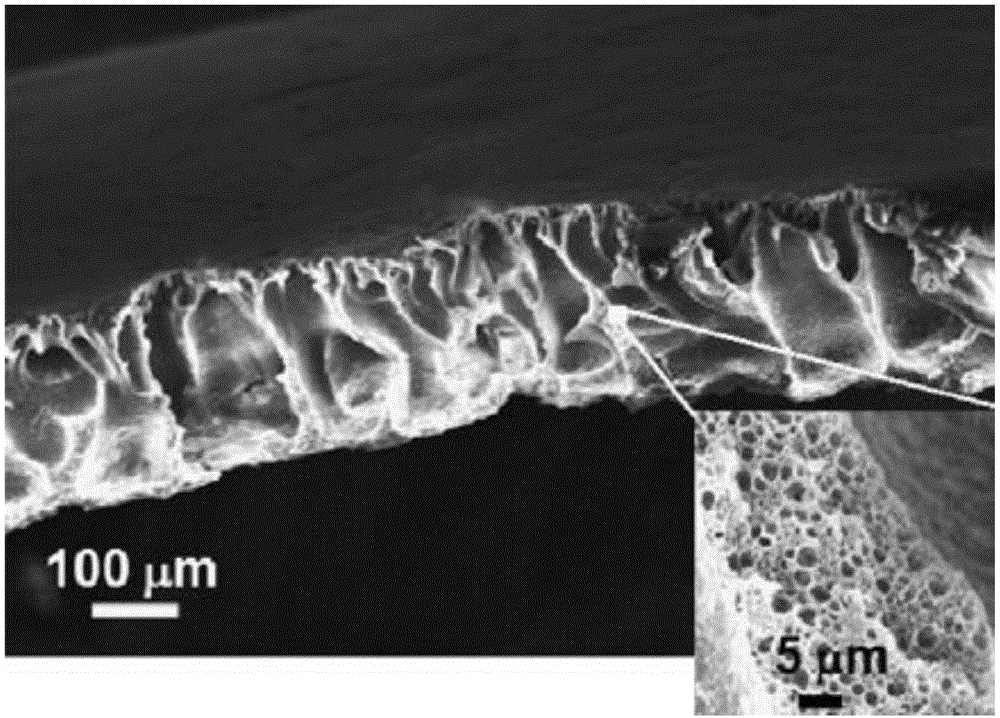

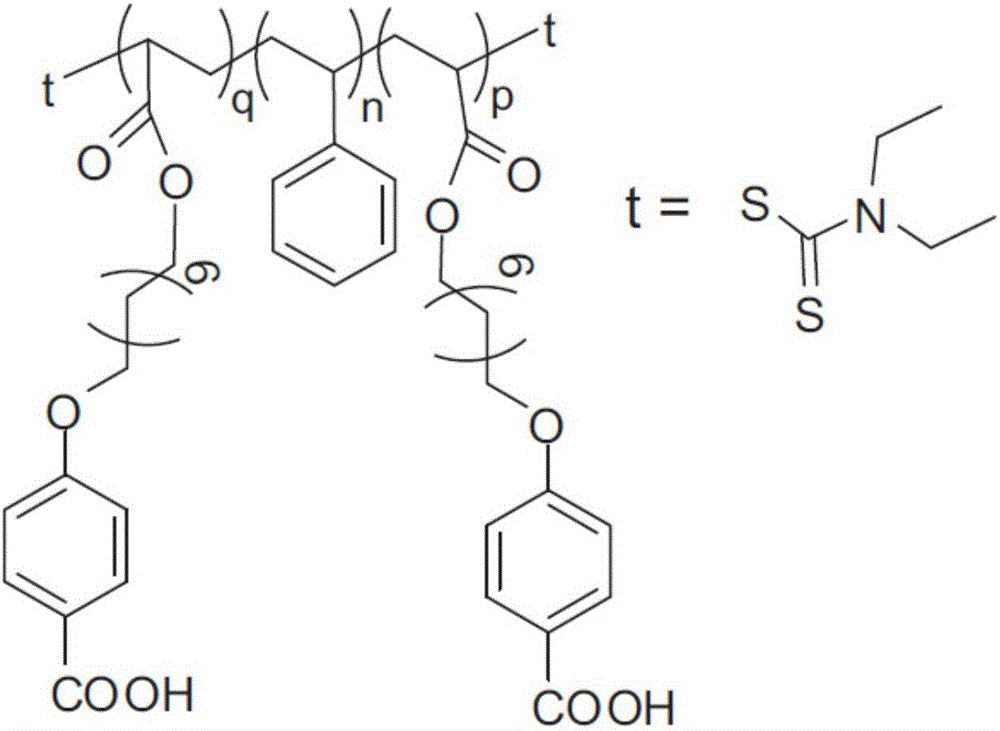

[0092] Prepare the separation membrane by the following method: the first monomer (3.5 parts by weight) shown in the above formula (2), the second monomer (0.726 parts by weight) shown in the above formula (3) and AIBN (0.045 parts by weight) The mixture is dissolved in the DMF solution, the concentration of the mixture in the DMF solution is 0.3g / mL, then the reaction system is deoxygenated (preferably deoxygenated by freeze-thaw cycles), and then the reaction system is sealed and heated to React at 80°C for 30 hours under stirring. After the reaction, methanol is added and exposed to air to terminate the polymerization reaction. Then add cold methanol that is 2 times the volume of the reaction system and ethyl acetate-petroleum ether (the volume ratio of the two is 1:4) mixture that is 1 time the volume of the reaction system to precipitate, filter, and dry to obtain the formula (3). The triblock copolymer shown. Polyvinylidene fluoride and triblock copolymer shown in formu...

Embodiment 2

[0094] Select domestic waste from the waste compression and transfer station in Haidian District, Beijing, and carry out high-temperature distillation carbonization on the above-mentioned waste through the following steps: (1) put the waste into the waste transport device; (2) pass the waste transport device through the high-temperature distillation carbonization (3) take out the gas flow of crude bio-oil and water vapor from the upper part of the high-temperature distillation carbonization device; (4) make the gas flow pass through the catalyst bed in gaseous form; (5) condense the effluent from the catalyst bed to obtain A mixture of upgraded bio-oil and water; (6) Obtaining charcoal materials from a garbage transport device passing through a high-temperature distillation carbonization device. The high-temperature distillation carbonization device is heated by high-temperature oxygen-free steam, the temperature of the high-temperature oxygen-free steam is 350°C, the nitrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com