Centrifugal separator for waste spinning fiber

A centrifugal and separator technology, used in centrifuges, solid separation, separation of solids from solids by air flow, etc., can solve the problem of inability to achieve single fiber classification and separation, and achieve low energy consumption and sorting efficiency The effect of high, simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with accompanying drawing and embodiment, and wherein accompanying drawing constitutes a part of this application, but those skilled in the art should know that the following embodiment is not the only limitation that the technical scheme of the present invention is done, Any equivalent transformation or modification made under the spirit of the scheme shall be deemed to belong to the protection scope of the present invention.

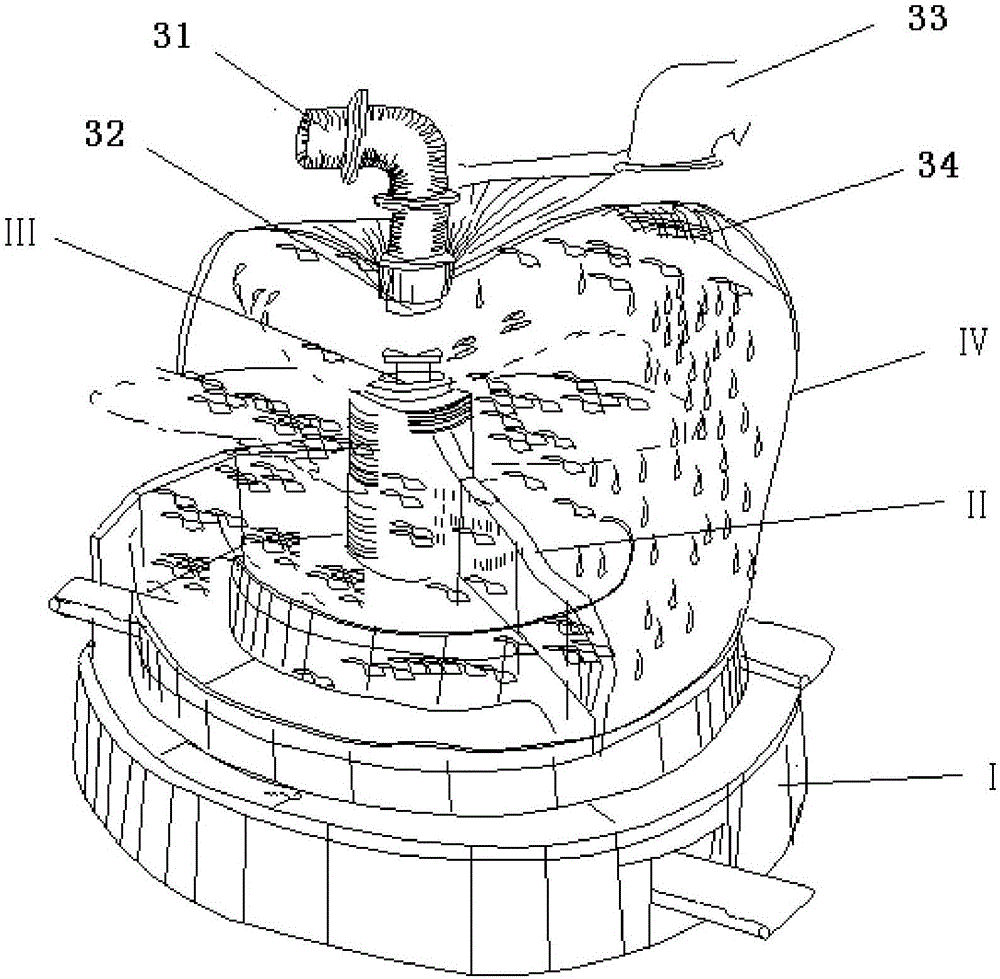

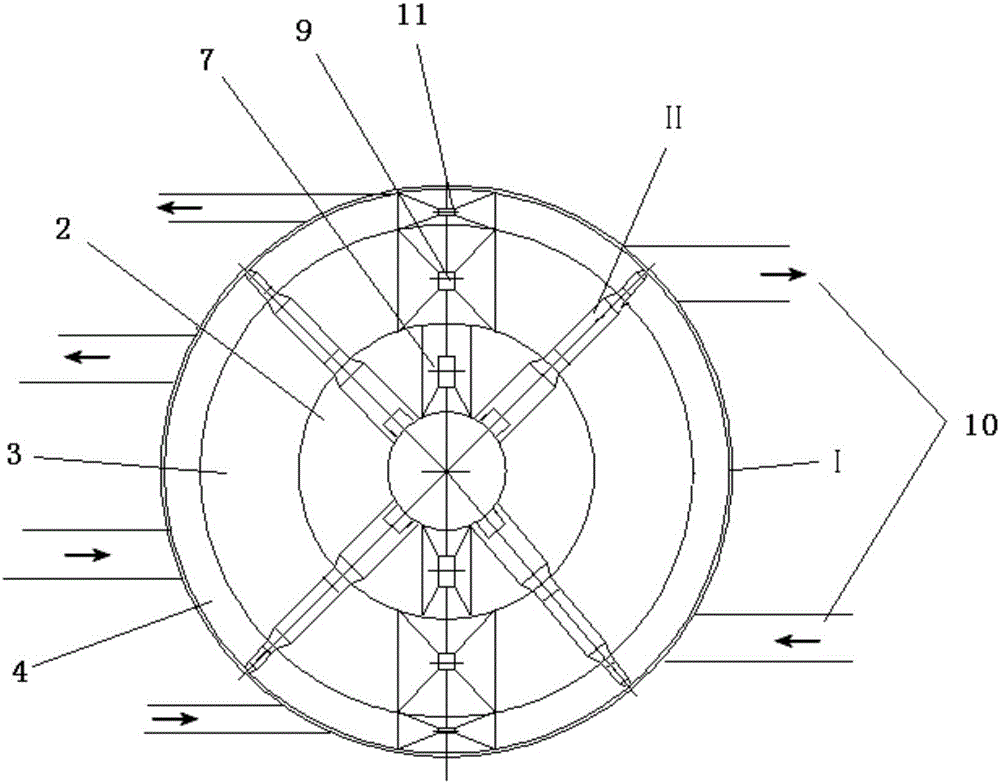

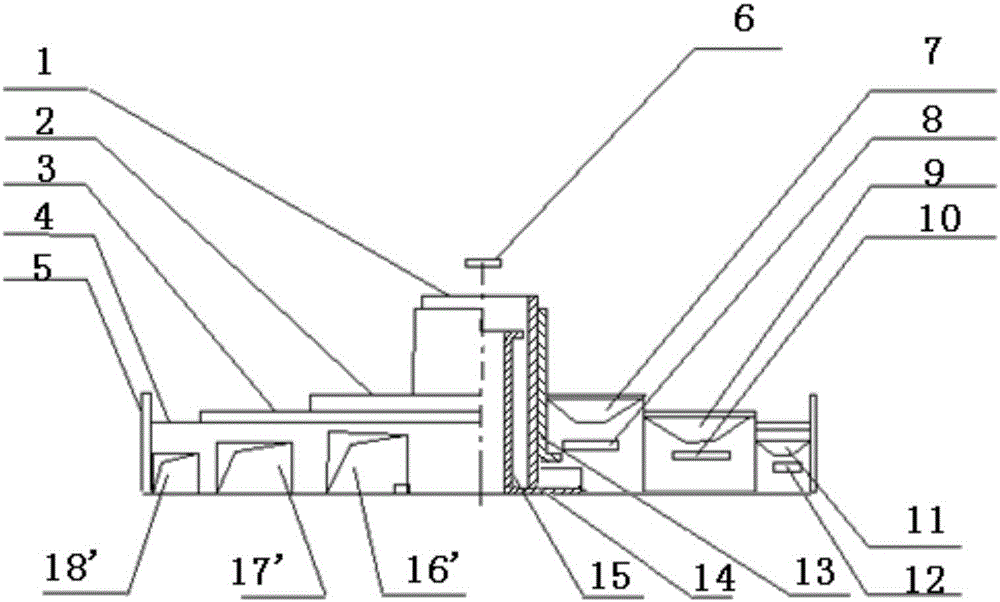

[0034] The machine utilizes the unique centrifugal effect formed by the special structure design, and obtains the classification of mixed recycled fibers, which can realize the separation of four types of fibers, namely: the separation of first-class fibers, second-class fibers, third-class fibers and waste spinning dust.

[0035] pass figure 1 , 2 As shown, the machine mainly includes four groups of parts: main frame I, rotary frame II, impeller assembly III, and hood assembly I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com