Preparation method of ZTA particle enhanced steel-based composite grinding roller based on chemical activation treatment

A technology of activation treatment and particle enhancement, applied in the field of wear-resistant material preparation, can solve the problems of poor bonding between ZTA particles and iron base, enhancement, and inability of ZTA ceramic particles to play a role, so as to enhance interface bonding and improve wear resistance. , the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

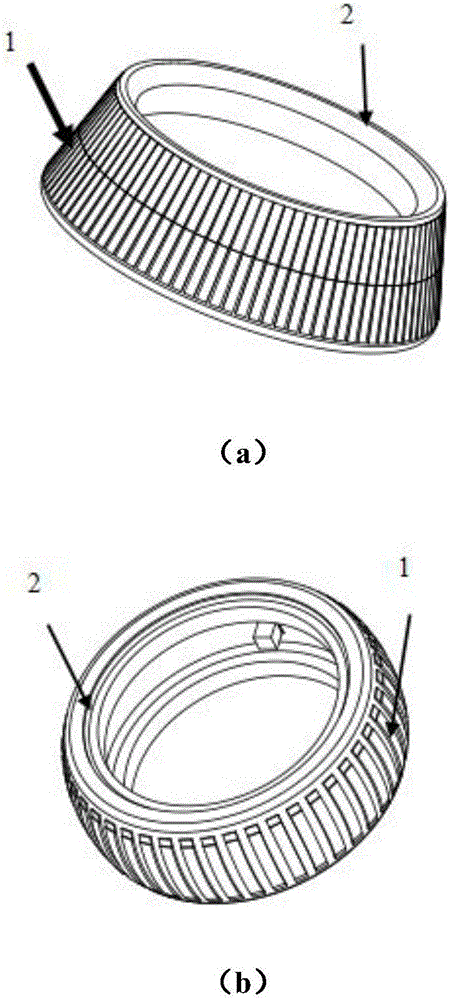

[0025] Embodiment 1: Grinding roller of column mill

[0026] 1) Mix titanium powder and inorganic salt, add ZTA particles and stir evenly to carry out high-temperature salt bath plating. The temperature of high-temperature salt bath is 750 ° C, and keep warm for 15 minutes to obtain a uniform coating; wherein, the mass ratio of titanium powder to inorganic salt is 10%, The mass fraction of ZTA ceramic particles in salt bath plating is 80%.

[0027] 2) Put the titanium-plated ZTA particles into the chemical plating solution, stir with a magnetic stirrer and heat to 70°C for 2 hours to obtain a nickel layer;

[0028] 3) Sinter the coated ZTA particles, raise the temperature from room temperature to 1200°C at a heating rate of 10-15°C / min, then raise the temperature to 1400°C at a heating rate of 5-8°C / min and sinter for 1 hour, then cool with the furnace , ZTA particles are interconnected to form a pore-like prefabricated body;

[0029] 4) Fix the prefabricated body in the san...

Embodiment 2

[0030] Embodiment 2: Cone type grinding roller

[0031] 1) Mix titanium powder and inorganic salt, add ZTA particles and stir evenly to perform high-temperature salt bath plating. The temperature of the high-temperature salt bath is 800° C., and keep warm for 30 minutes to obtain a uniform coating; wherein, the mass ratio of titanium powder to inorganic salt is 14%, The mass fraction of ZTA ceramic particles in salt bath plating is 75%.

[0032] 2) Put the titanium-plated ZTA particles into the chemical plating solution, stir with a magnetic stirrer and heat to 75°C for 4 hours to obtain a nickel layer;

[0033] 3) Sinter the coated ZTA particles, raise the temperature from room temperature to 1200°C at a heating rate of 10-15°C / min, then raise the temperature to 1400°C at a heating rate of 5-8°C / min and sinter for 1 hour, then cool with the furnace , ZTA particles are interconnected to form a pore-like prefabricated body;

[0034] 4) The prefabricated body is fixed in the s...

Embodiment 3

[0035] Embodiment 3: tire type grinding roller

[0036] 1) Mix titanium powder and inorganic salt, add ZTA particles and stir evenly to carry out high-temperature salt bath plating. The temperature of high-temperature salt bath is 800° C., and keep warm for 45 minutes to obtain a uniform coating; wherein, the mass ratio of titanium powder to inorganic salt is 15%, The mass fraction of ZTA ceramic particles in salt bath plating is 65%;

[0037] 2) Put the titanium-plated ZTA particles into the chemical plating solution, use a magnetic stirrer, stir and heat to 85°C for 6 hours to obtain a nickel layer;

[0038] 3) Sinter the coated ZTA particles, raise the temperature from room temperature to 1200°C at a rate of 10-15°C / min, and then increase the rate of temperature to 1400°C at a rate of 5-8°C / min for sintering for 1 hour, then cool with the furnace , ZTA particles are interconnected into a pore-like prefabricated body.

[0039] 4) The prefabricated body is fixed in the sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com