A five-axis three-dimensional ultrasonic polishing machine tool and using method thereof

A three-dimensional ultrasonic and machine tool technology, applied in the field of polishing machinery, can solve the problems of insufficient processing efficiency and low polishing power, achieve the effects of saving polishing liquid, increasing the polishing area, and avoiding the adverse effects of processing quality and polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with drawings and embodiments.

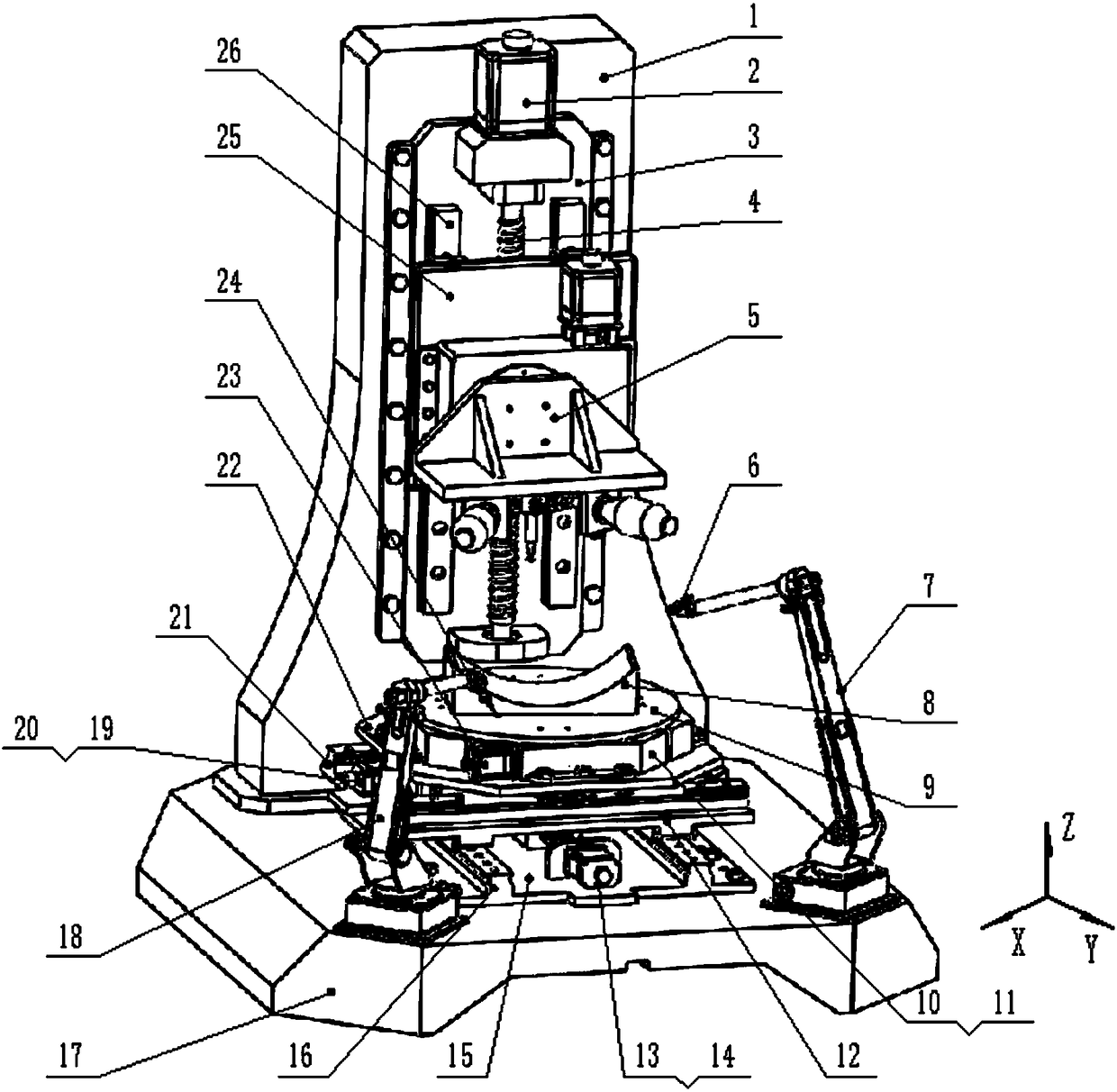

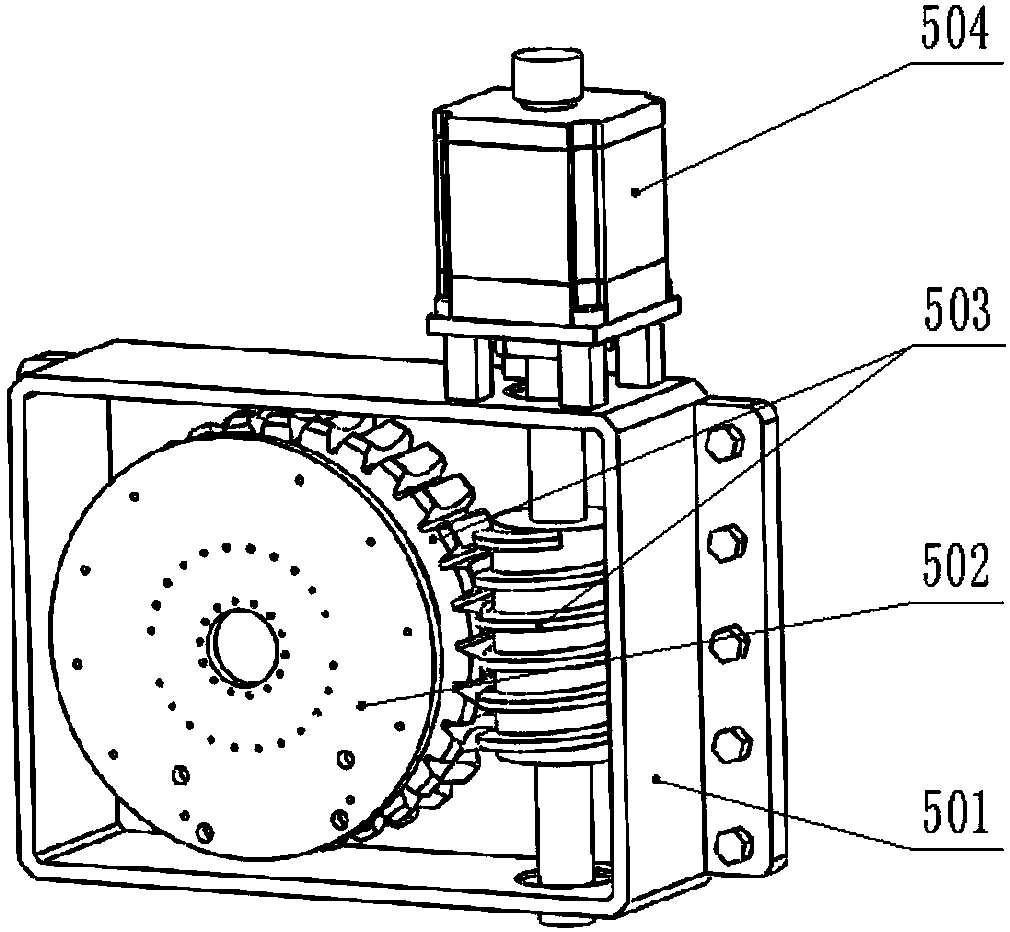

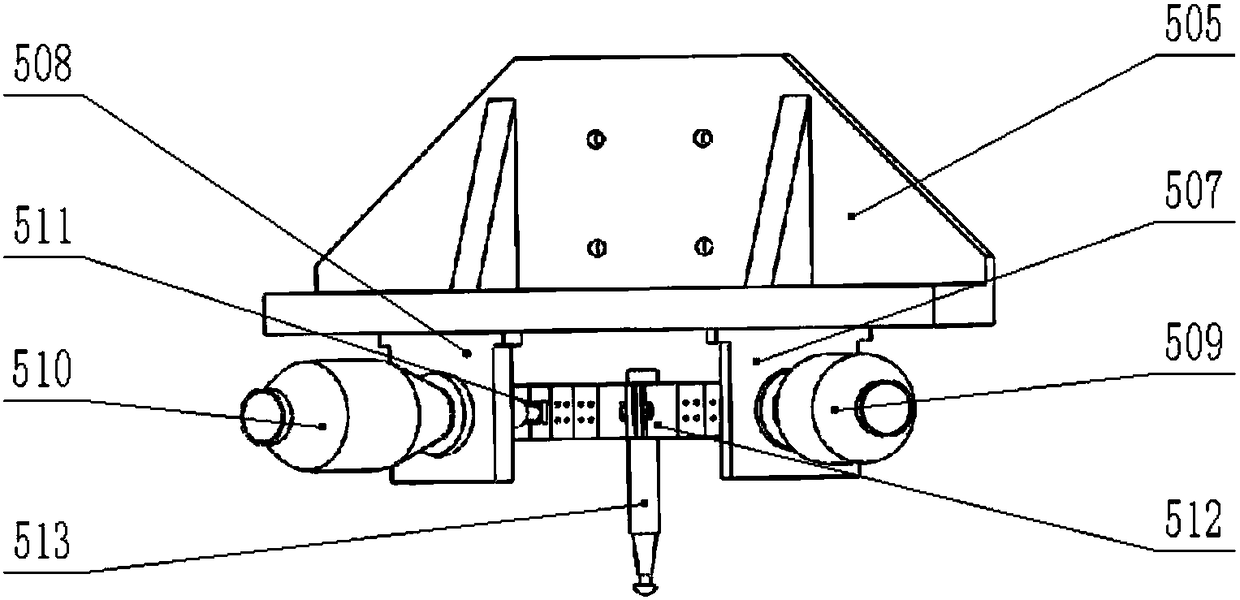

[0041] like figure 1 As shown, the five-axis three-dimensional ultrasonic polishing machine tool of the present invention includes a frame; an X-direction movement mechanism, a Y-direction movement mechanism and a Z-direction movement mechanism installed on the frame; an ultrasonic vibration polishing device 5; a rotary table; Atomizing liquid applicator and workpiece on-line detection device.

[0042] The frame includes a machine base 17 and a bed 1 vertically fixed on the machine base; on the base.

[0043] The Z-direction moving mechanism includes a Z-direction rail seat 3 fixedly installed on the front wall of the bed, Z-direction rail seats 26 on both sides of the front of the Z-direction rail seat, and a Z-direction mobile platform 25 on the Z-direction rail. The moving platform is driven by the Z-direction servo motor 2 installed at the rear of the Z-direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com