Production method and production device for formaldehyde-free type medium-density fiberboard

A production device and medium-density technology, applied in the pretreatment of molding materials, household components, flat products, etc., can solve the problems of increasing 50 yuan, increasing production and operation costs, and long curing time, so as to reduce deformation and shorten Heat-pressing time and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

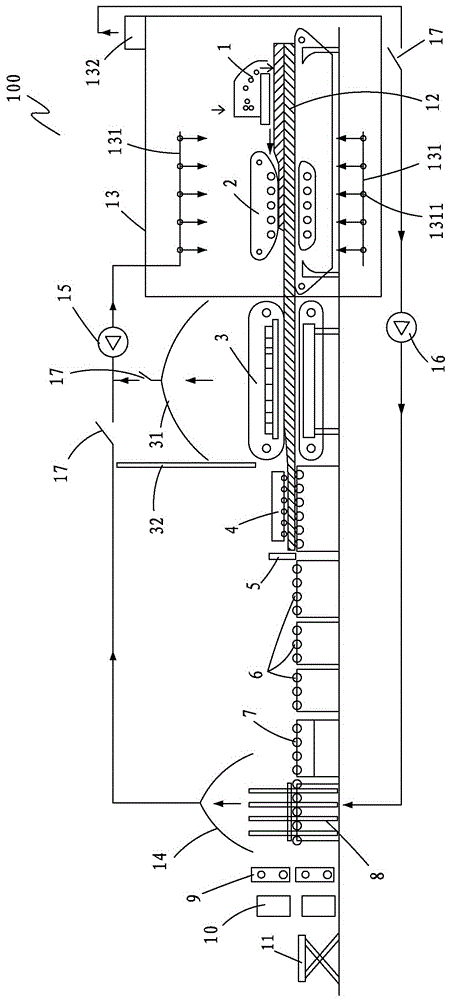

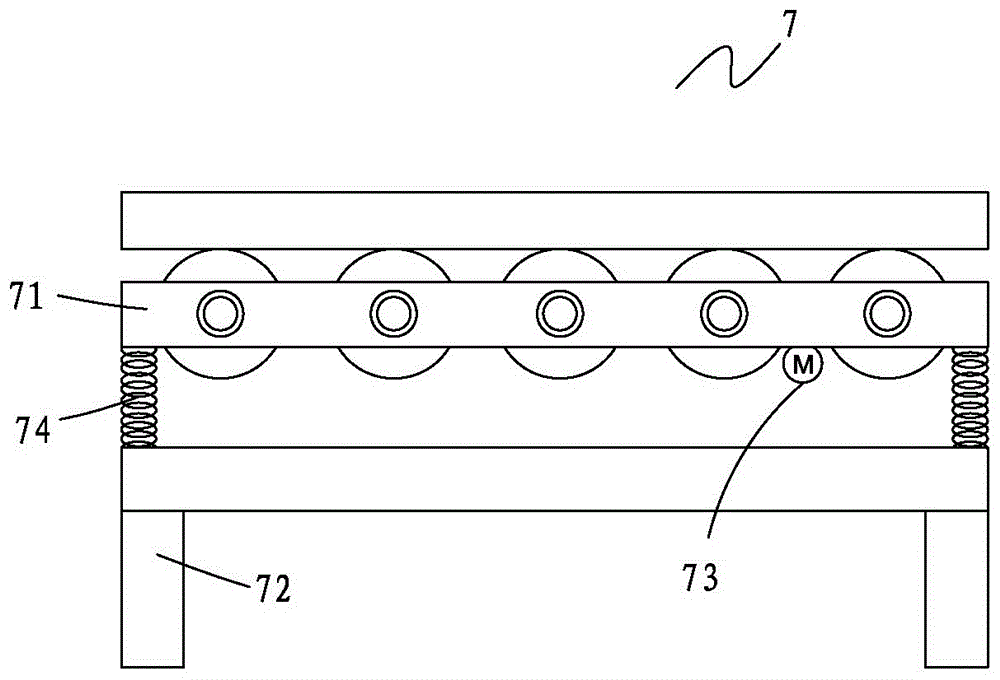

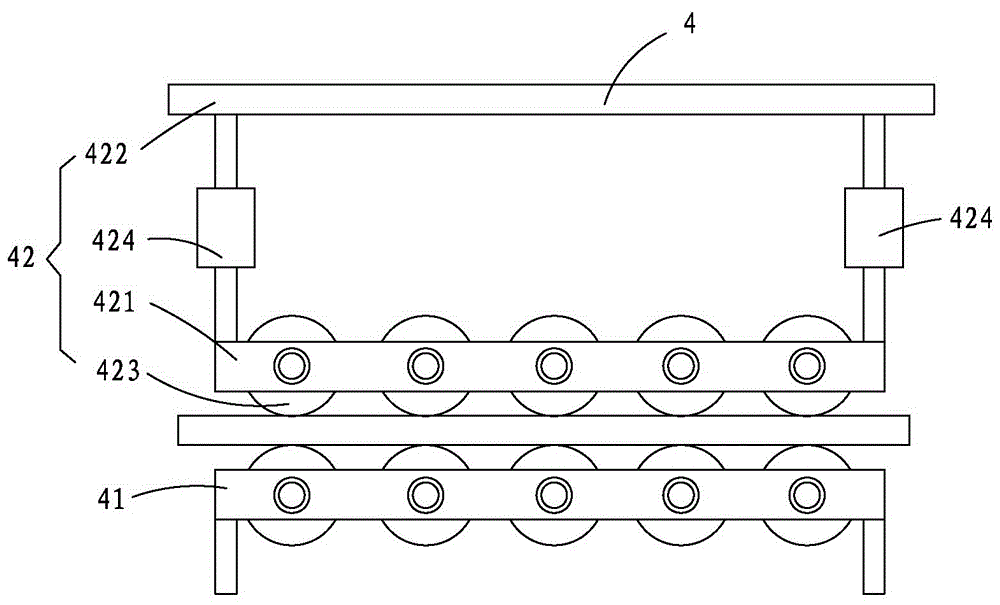

[0024] see figure 1 and figure 2 , image 3 As shown, a production device for formaldehyde-free medium density fiberboard includes a paving machine 1, a pre-press machine 2, a hot press machine 3, a cold-press rolling machine 4, and a pair of Angle saw 5, the first roller conveyor 6, shaking conveyor 7, cooler 8, sander 9, panel cutting machine 10 and stacker 11, also includes belt conveyor 12, heating chamber 13, draft cover 14, the first A fan 15 and a second fan 16.

[0025] see again figure 1 and figure 2 , image 3 As shown, the paving machine 1, the pre-pressing machine 2 and the belt conveyor 12 are located in the heating chamber 13; the heating chamber 13 has two air delivery pipes 131 and an air outlet 132, and the two air delivery pipes 131 are arranged horizontally on the Above and below the paving machine 1 and the pre-pressing machine 2, and each air delivery pipe 131 is provided with a plurality of air outlets 1311; The top of 14 communicates with an end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com