A biological turntable treatment method for synthetic leather wastewater

A biological turntable and treatment method technology, applied in the direction of sustainable biological treatment, biological water/sewage treatment, natural water treatment, etc., can solve the problems of low treatment efficiency, single disc shape, small specific surface area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

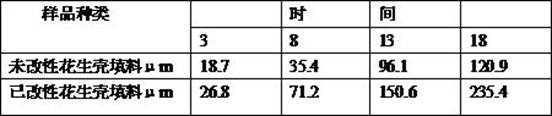

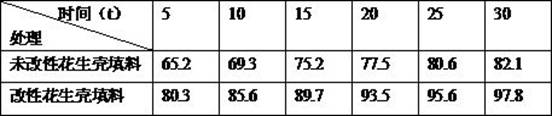

[0025] The biological turntable directly uses chitosan fiber net to make a cage instead of a disc, and adds modified peanut shell filler in the cage, the biofilm can be fixed on the surface of the filler and the cage, and the lower half of the cage is immersed in water. As the rotating cage rotates, the carrier and the biofilm on the rotating cage are alternately exposed to air and submerged in water to achieve the purpose of oxygenation and wastewater treatment. Chitosan fiber is made of chitosan as the main raw material, dissolved in an appropriate solvent, prepared into a certain concentration of spinning stock solution, and then processed by spinning, coagulation forming, stretching and other processes to obtain high molecular weight with a certain strength. functional materials. The modified peanut shell filler is to wash the peanut shells with tap water and deionized water, dry, crush, and sieve to make peanut shell particles between 300 μm. The above peanut shell parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com